With stepper motors, the rotor moves around its circular path in multiple individual steps. By switching the stator windings on and off in a targeted manner, it can be moved into specific positions. This mode of operation differentiates it in principle from conventional electric motors with continuous rotation.

When the power supply is switched off, the rotor remains in the most recent step position and its magnets provide a currentless static torque. This is particularly advantageous in many battery-driven applications. As the motor controller counts the steps completed, it also performs the function of an encoder. In general, an additional encoder is not required for operation.

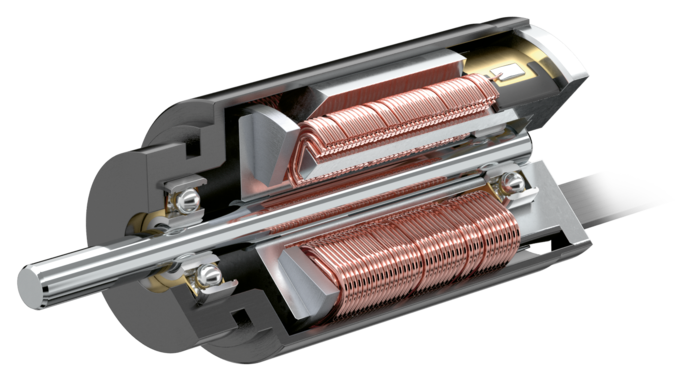

How are FAULHABER stepper motors designed?

The stepper motors from FAULHABER are all two-phase devices and are designed as permanent or disc magnet motors. In the latter case, up to 25 pole pairs are arranged like pizza slices on the disc magnet of the rotor. The windings of the one- or two-piece stator are positioned perpendicular to the disc magnet. In permanent magnet motors, the rotor consists of a plastic sleeve that contains multiple small permanent magnets. The windings are housed in a two-piece stator. The rotor runs between the stator halves.

Regardless of their number and arrangement, the stator windings are energized alternately in two phases. With each phase, the rotor moves by one magnetic pole segment. Both stepper motor variants have a range of design-related strengths, in comparison with both conventional DC motors and the hybrid stepper motors that are used in large numbers in electronic mass products.

Conventional stepper motor technologies are generally optimized for one of several characteristics such as speed, torque or precision. However, the stepper motors from FAULHABER achieve top values in multiple categories simultaneously. In terms of positional accuracy, they attain absolute peak values. For example, the maximum positional deviation when using a FAULHABER stepper motor with a lead screw can be less than two microns. Like all motors from FAULHABER, the steppers are also characterized by maximum power with the smallest volume.