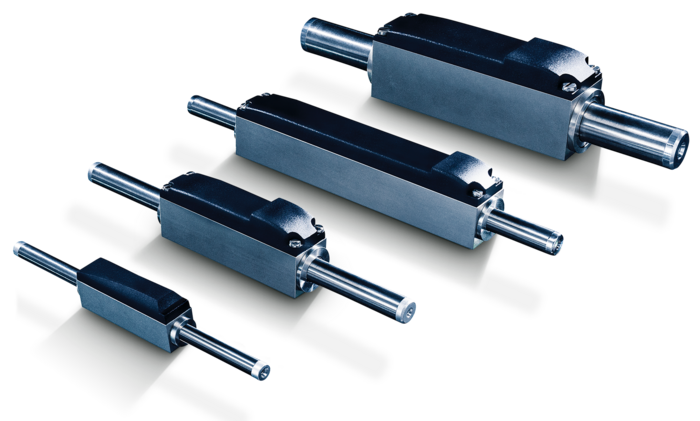

The conventional electric motor generates its force from a rotational motion; its rotor and stator are positioned in a circular arrangement. In contrast, the linear motor has a forcer rod rather than a rotor as its moving component. Its forcer rod and stator are virtually "rolled out" and placed on top of each other in their straight form. As a result, with a linear motor, the torque is produced in a straight line and the forcer rod moves back and forth along one axis.

How are FAULHABER linear motors designed?

In linear motors, the winding can be either the stator or the rotor. The permanent magnets each act as the corresponding counterpart. However, with FAULHABER, the neodymium permanent magnets are always housed in the forcer rod, while the coil acts exclusively as the stator. This design enables small linear motors with a particularly small volume that can also produce a very high torque.

The oblong-shaped winding of the linear motor is self-supporting and coreless so that no cogging torque is generated. It is split into three electrically isolated segments and is hollow inside. In this cavity is where the forcer rod moves; the two components are separated by a small air gap. In the forcer rod, multiple magnets are glued behind one another in a rod shape, with the matching poles meeting in each case (north-north, south-south).

The forcer rod is the only moving component of the linear motor. It has a lubrication-free sleeve bearing made of wear-resistant polymer at each end of the stator. This design is the basis for the extremely long service life of the linear motors from FAULHABER: Depending on the type of load that is moved in the application, they can perform between several million and several hundred million cycles.