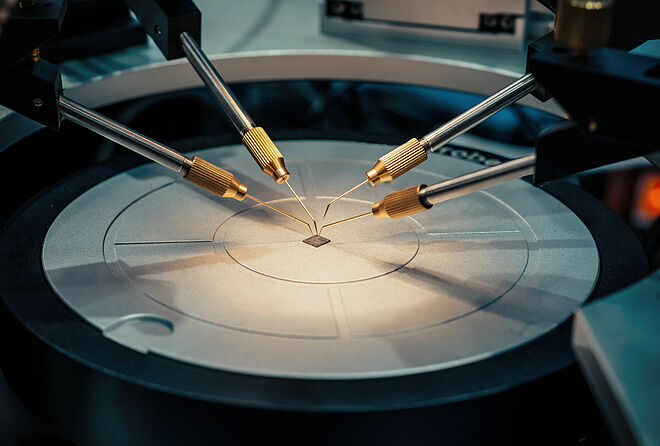

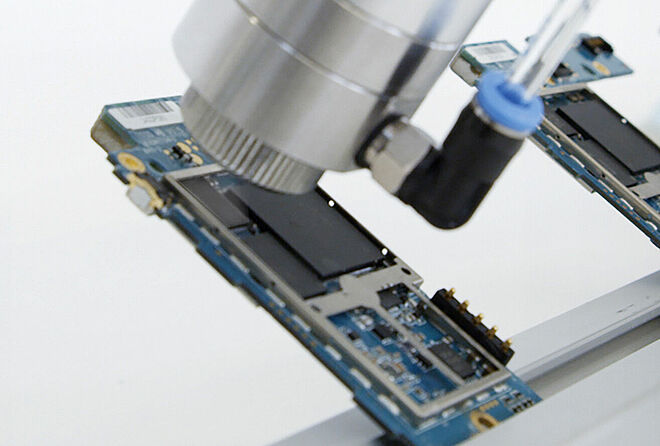

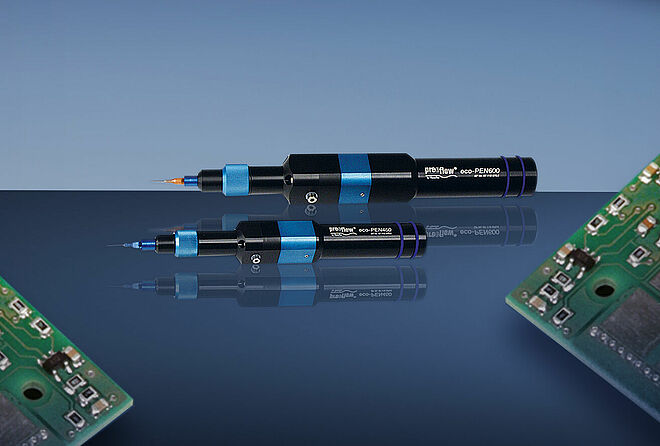

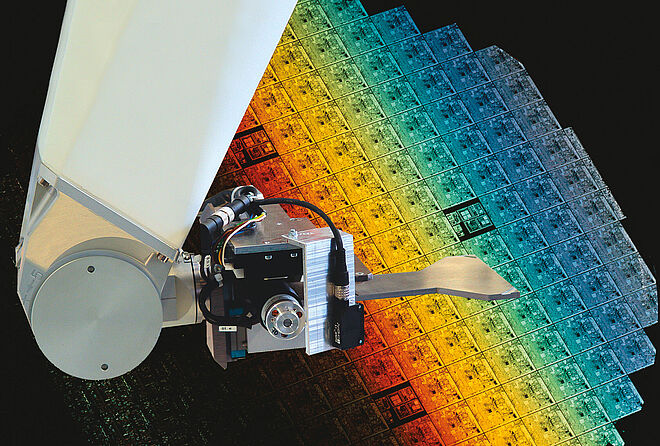

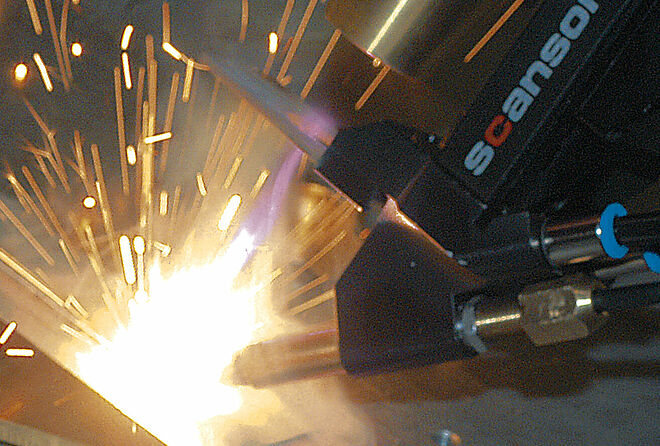

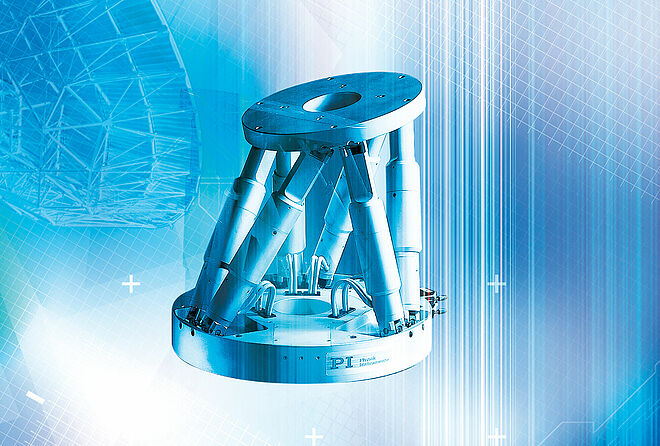

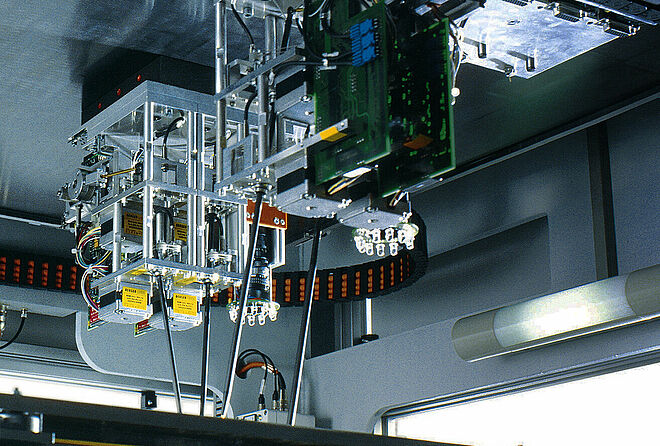

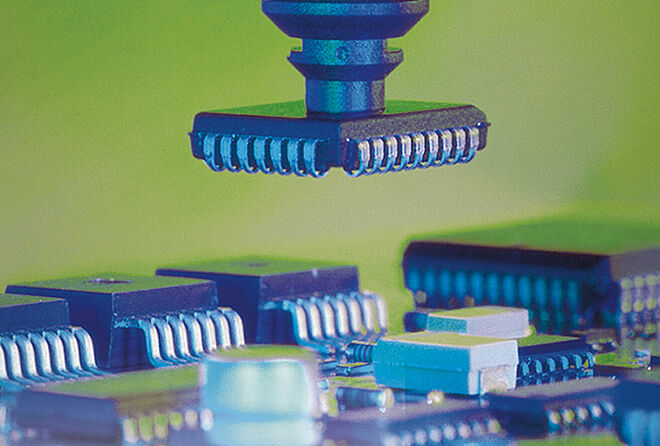

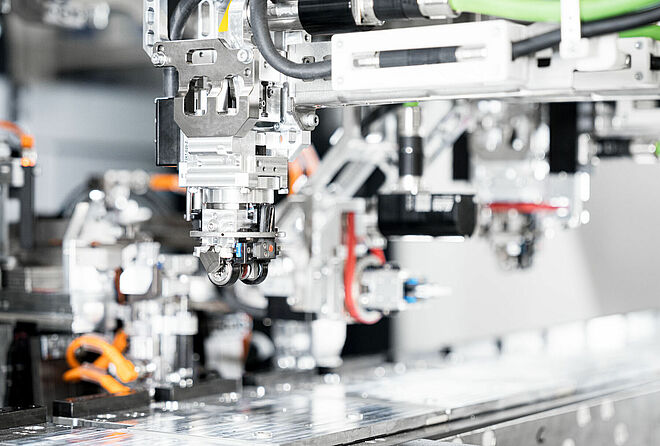

A "compact automation" is a mechatronic system that performs a whole series of consecutive production steps autonomously. "Compact" refers to the small dimensions, in the millimeter and centimeter range, of the products to be processed. Designing and constructing such systems is one...