Testing and vaccines provide the way out of the coronavirus lockdown and a gradual return to normality. But the measures introduced by the authorities to contain the pandemic were quickly exhausted. Because the exponential spread of the virus led to a soaring global demand for tests and vaccines. In the beginning, the capacities were insufficient, and the wait for test kits and vaccines really put the patience of the world to the test.

Laboratory automation against Covid-19

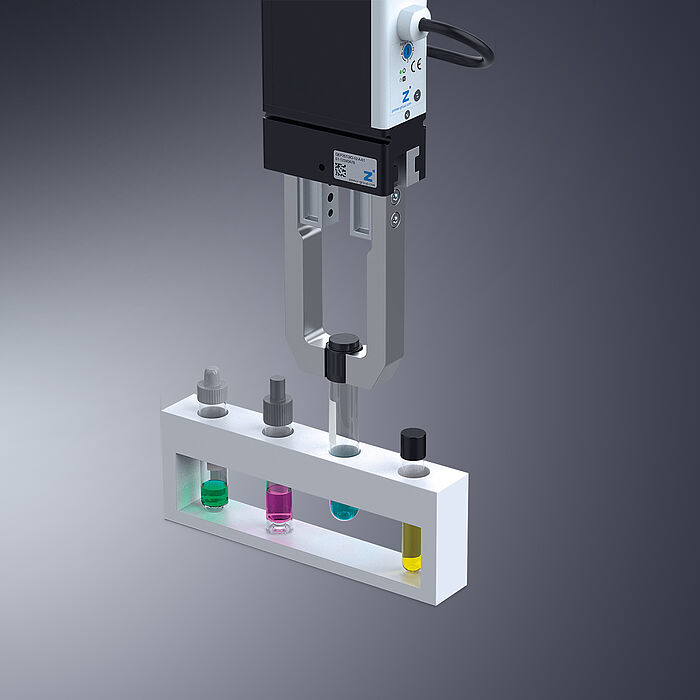

The pharmaceutical industry, medical technology, and medical laboratories did actually work extremely quickly. This also applies to the expansion of production and to the increase of testing capabilities. A key factor in this success was automation. In laboratories, the pandemic proved to be a major impetus for automation. Automatic laboratory devices and universal, flexible robots can relieve specialists of a great deal of work and increase both throughput as well as efficiency. The automatic gripping and handling of samples, pipettes, or reagents is among the central, constantly recurring process steps here. For this purpose, delicate, industrial small parts grippers are required.

Two different technologies are generally available for gripping, explains product manager Maik Decker, who is responsible for this area at the southwest German manufacturer Zimmer Group: "Up until now, most grippers in industry have been powered pneumatically, i.e., with compressed air. This technology is, however, not suitable for the hygienic environments required in laboratories, in medicine and in the pharmaceutical and medical technology industries. Grippers with electric drive are therefore used in these areas."

Electric motor makes grippers flexible

In addition to the hygienic aspect, these grippers have another advantage: they function without a compressed air system and the associated lines. In some industrial sectors, these are standard equipment in production facilities – electricity is, after all, available everywhere. Besides, the machines in which the grippers are installed operate with electric power. An electrical connection is much easier to install than a compressed air supply. Moreover, the control of electric components is both simpler and more flexible than working with pneumatics. "We see a clear trend toward the electric drive, not least in the automotive industry," explains Maik Decker.

New products from the Zimmer Group, such as the new GEP2000 series, serve and consolidate this trend. The small parts gripper can – depending on the version – grip and hold components weighing up to five kilograms but can likewise handle delicate and sensitive parts such as a test tube without problem. "The advantages of the electric drive also include the ability to adapt the gripping force to various objects at any time," explains Volker Kimmig, team leader for software at the Zimmer Group. "With the appropriate controller, the gripper can switch between different parts during a running process."

10 million cycles without maintenance

The power for these work steps is supplied by a brushless DC-servomotor of the BX4 series from FAULHABER. In addition to a high torque, the strengths of the four-pole drive include its low vibration and low noise, compact design and a long service life. "We guarantee that this product will perform over 10 million cycles without maintenance," says Volker Kimmig. "This is, of course, only possible with a motor of very high quality." Such a motor must also provide a number of additional features to meet the demands of continuous operation in a typical pick-and-place application.

The development engineer uses the production of car keys as a good example: "Large quantities and high throughput set the tone here. The gripper robots work under very high-paced, permanent stress with short cycle times. The motor must therefore start and then stop again at very short intervals. Decisive here is the motor's acceleration, as every tenth of a second counts in the process as a whole. Moreover, the motor needs to be able to efficiently dissipate the heat that forms in such an operation in order to eliminate the possibility of overheating."

Proven collaboration

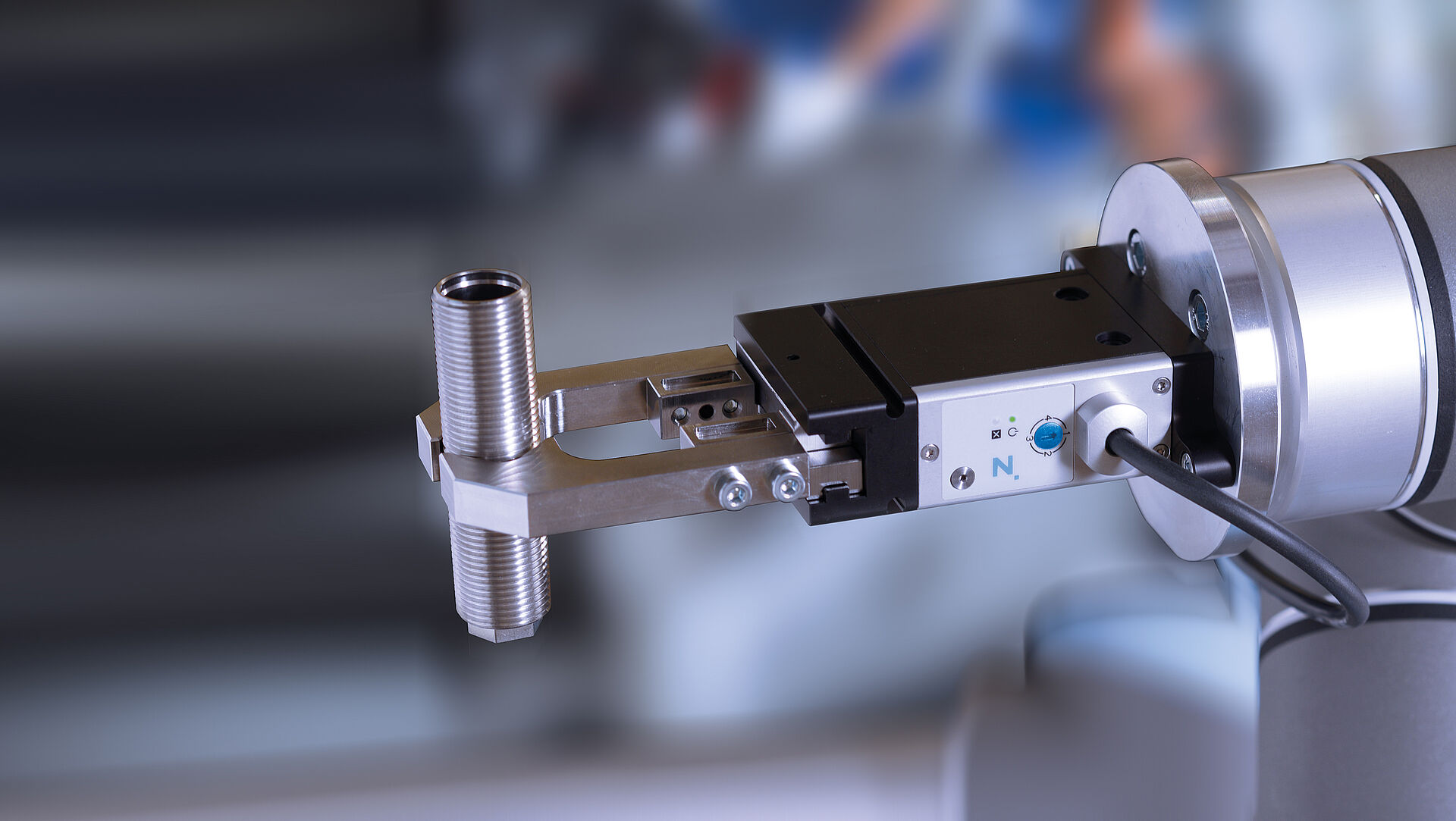

The gripper experts from the Zimmer Group knew, not only from the data sheet, that the BX4 from FAULHABER would satisfy these requirements. They had previously installed motors of this series in their GEH6000 gripper family. Essentially, this so-called long-stroke gripper works in the same ways as the small parts gripper. Its stroke, i.e., the distance between the open and closed position of the gripper jaws, is significantly larger and can be up to 80 millimeters.

"The device can thus cover a wider range of different-sized target objects in the same process," explains Maik Decker. "The smaller GEP2000, on the other hand, can also perform its work in very confined conditions. Of course, this only functions with a motor that delivers very high power in a very small space."

Mechanical self-locking

The gripper series have one special feature in common with other Zimmer Group products: The motor power is transferred to the jaws by a worm gear drive with a steep pitch. Even in the event of a power failure, the gripping force is retained and the respective position held. Once gripped, a work piece is held securely by this mechanical self-locking function, without an additional device such as a brake being required.

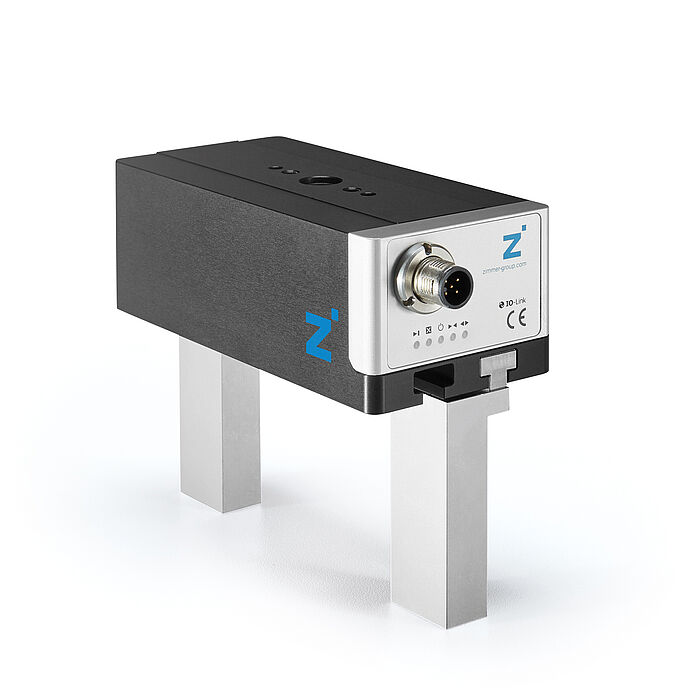

The drive electronics in the two gripper types operate slightly differently. With the GEH6000, the encoder signals of the drive are used for positioning the jaws; with the GEP2000, this task is performed with the help of a positioning sensor. Both solutions achieve a very high degree of repeatability: the specified path of the jaws is reproduced to within one five hundredths.

"In many applications, the prepositioning when lowering the gripper to the target object is very important," explains Volker Kimmig. "In constrained spaces, the open position is often only allowed to be very slightly larger than the closed position. When "maneuvering" a robot arm in a complex environment, it may also be necessary to make very precise presettings. We do this using very precise electromechanics, where the motor once again plays a crucial role, as well as with a flexible data connection. Our devices can be equipped with IO-Link and with digital I/O. This makes it easy for them to move in and back out again just about everywhere."

Products