The smaller a device can be built, the easier it is to transport, install or integrate into existing systems. In addition, precision production processes for metal, ceramic or plastic components allow for closer fits and narrower gaps. This then has a very beneficial spinoff on the efficiency of small and miniaturized fluid machinery such as displacement pumps. German manufacturer HNP Mikrosysteme GmbH is exploiting these new possibilities with its compact, hermetically sealed micro annular gear pump for continuous dosing – even suitable for corrosive media. To achieve a drive with dimensions and output ideally tailored to the pump delivery characteristics, HNP pump specialists worked with Schönaich-based drive expert FAULHABER. The result was a compact pump/drive delivery unit suitable for a large number of applications, including the more exotic.

Accurate and high-performance pumping

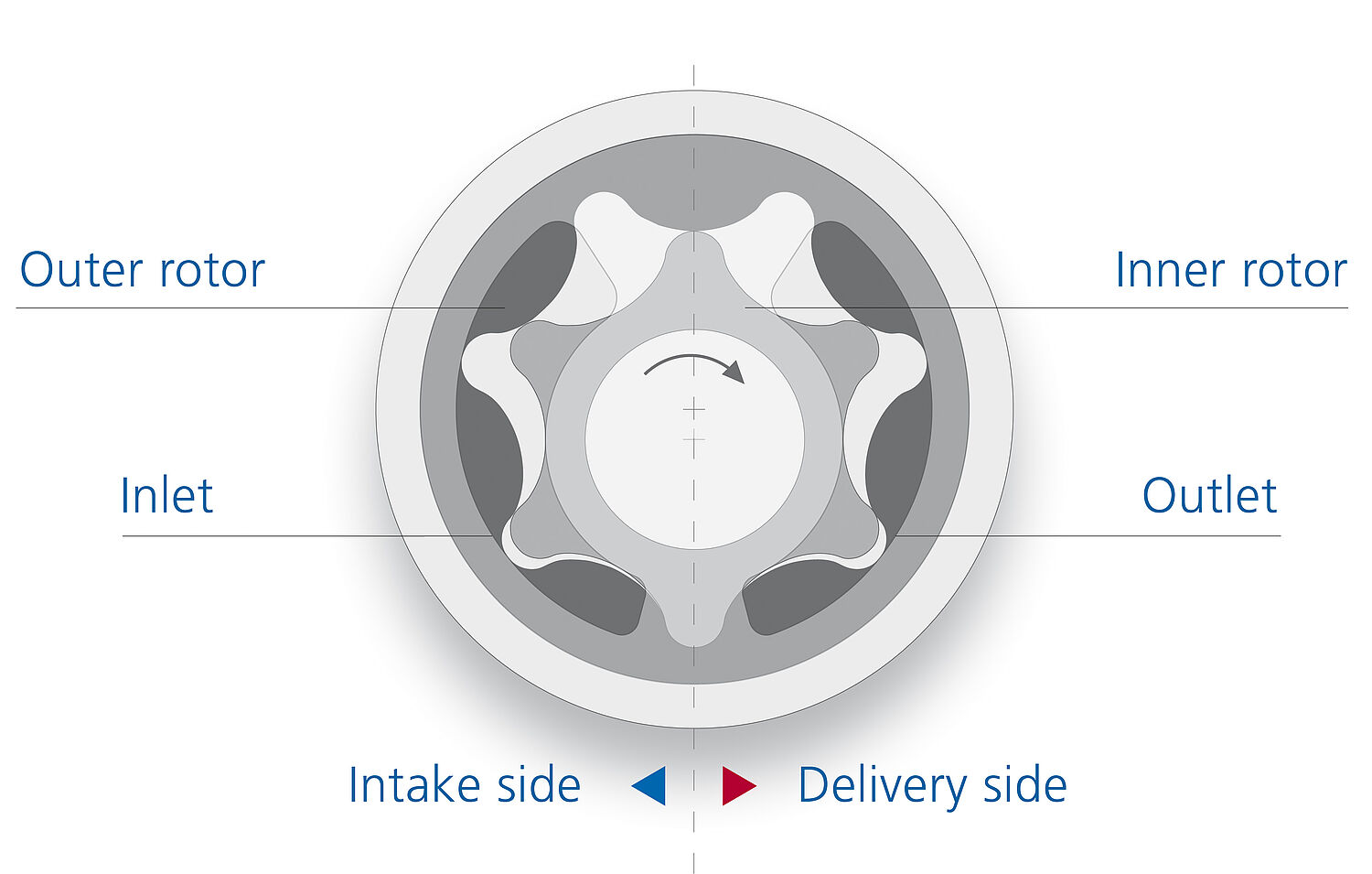

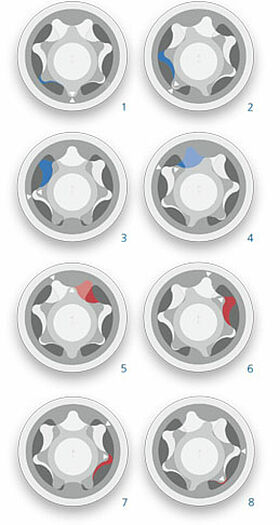

There is a wide range of applications requiring the targeted dosing of small volumes of liquid. High-tech solutions are called for if the application also requires a long service life and a seal-less pump design. Typical areas of application are the transfer of crystallizing, air-sensitive or outgassing media, fuel cell technology, the delivery of urea solution (AdBlue) to remove NOx from diesel engine exhaust gas, or dialysis and analysis technologies. The hermetically sealed pump head is driven by means of a powerful rare earth magnetic coupling, which prevents leaks on the drive end. In combination with the materials available, such as nickel-based carbides, stainless steels, ceramics based on aluminum, zirconium oxide or silicon carbide, and plastics such as PTFE, PEEK and FKM, the pumps can be adapted to various media, including corrosive substances. The pump, only 22 mm in diameter and 69 mm long, and weighing around 100 g, is designed for 24 V operating voltage and can transfer 4.8 to 72 ml/min at up to 5 bar delivery pressure. Thanks to the annular gear design, the pumpable viscosity range is between 0.3 and 100 mPas, with a pulsation of around 6% and a differential pressure range of 0 to 5 bar. The no-valve annular gear principle guarantees minimal shear forces during pumping.

Compact microdrives

The pump is driven by an electronically commutated DC motor with integrated speed controller. The brushless design enhances the service life and reliability of the drive. Motor-adapted variable speed control is guaranteed by a speed controller that has the same diameter as the motor and is mounted to the rear of the motor. This means that the user can easily adjust the speed via an analog input with 0 – 10 V. A digital input determines the direction of rotation. For additional monitoring functions, the digital frequency output provides a 15-mA output signal with six pulses per revolution. The drive supply voltage is 12 or 24 V DC, while the 22 mm motors achieve around 9 W and feature a torque of up to 59.9 Nm. Supply voltage to the speed controller is 5 to 28 V DC via a separate flat ribbon cable. The motor efficiency of around 68%, as well as the more than 95% efficiency of the control electronics, allow for long operating times even in battery-backed mobile devices. The rugged stainless steel enclosure and wide temperature range of –40°C to +85°C enable the device to also be used outdoors, e.g. for environmental measurements. The short-term overload capability of the microdrives supports such applications, as this allows increased pump breakaway torques, e.g. after overnight temperature drops, and the resulting higher fluid viscosity, to be mastered with ease.

Products