In addition to light, water and trace elements, plants need just six nutrients: phosphorus, potassium, magnesium, calcium, sulfur and nitrogen. The last of these, denoted with the chemical symbol N, is the most important in terms of quantity. It is needed for, among other purposes, the formation of protein compounds and chlorophyll as well as for the growth of shoots and leaves.

Nitrogen is the main constituent of the earth's atmosphere. It is present there in abundance in its elementary gaseous form (N2). Unfortunately, most plants are not able to do anything with it in this state. They can only absorb nitrogen from the soil through their roots and need it in the form of ammonium (NH4+) or as nitrate (NO3–).

Nitrate compounds make up the majority of the fertilizers with which modern agriculture achieves high yields. Applied at the right time and in the right quantity, they can be absorbed nearly completely by the plants and converted into food and biomass. Subsequent problems only arise if too much nitrate lands in the fields. Sooner or later, excess nitrate seeps into the groundwater with the rain.

Refining the spreading pattern

The conventional method for spreading mineral fertilizers on a field uses so-called twin disk spreaders: The fertilizer falls out of the reservoir container behind the tractor onto two horizontally rotating disks. Their rotary movement ejects the grains up to 25 meters to the left and right as the machine drives over the field. While this allows large areas to be fertilized in a short amount of time, the distribution is performed at a fixed rate and is calculated on the basis of the total area. The "spreading pattern" is imprecise; in the case of irregular field shapes, in curves and along the edges of roads, there are inevitably strips that receive too little or too much fertilizer. Moreover, ejecting the fertilizer through centrifugal force only functions reliably with fertilizer grains that are of uniform size and quality.

"We are able to avoid all of these drawbacks with our precise fertilizer spreaders of the Aero series," says Maximilian Zimmer. He is the team leader for electronics development at RAUCH Landmaschinenfabrik in Sinzheim (Baden-Wuerttemberg, Germany). "Here, the granulate is not ejected over a large area but instead lands on the field through a system of tubes in the correct quantity and finely dispersed. During this process, the machine can block out specific areas that require no fertilizer."

Dosing system with switchable sections

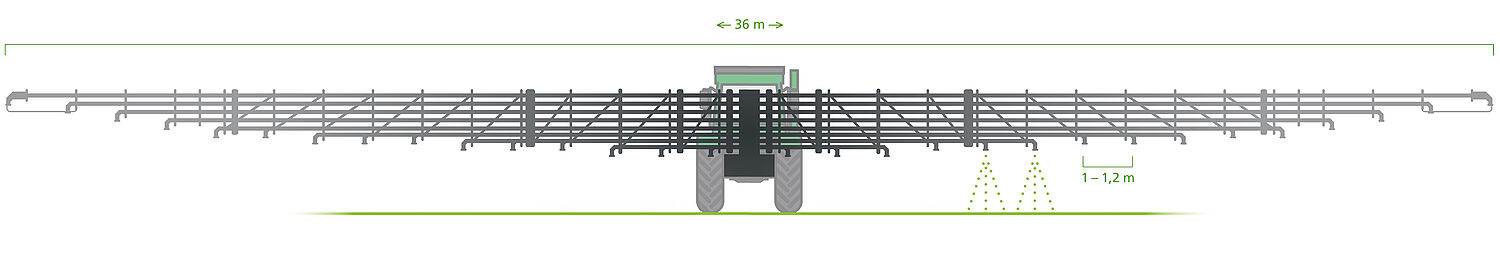

The basis for such precision fertilization is the MultiRate dosing system which, according to the manufacturer, is "the world's first dosing and distribution system for granulated fertilizer for small-scale and precise plant nutrition" for pneumatic fertilizer spreaders. It allows thirty spreading sections to be switched on and off individually. At the same time, the applied quantity can be controlled individually for each section. This allows a reduction in fertilizer usage per unit area of up to 23 percent as well as a significant increase in yield.

The fertilizer granulate lands on the field through thirty individual tubes, precisely dosed in strips of 1 to 1.2 meters in width. Each individual infeed uses sophisticated technology: The fertilizer is guided through multiple funnels to six metering shafts with five segments each.

These are CAN-bus-controlled and are equipped with cam wheels that divide the granulate into small portions. The granulate is then accelerated by a stream of air and transported to the outlet.

Motor speed controls fertilizer quantity

Each cam wheel segment is moved by a FAULHABER brushless flat motor of the 4221…BXT series with a special customer-specific gearhead and can be individually actuated. "The speed of the motor controls the quantity of the fertilizer applied," explains Maximilian Zimmer. "The machine can thereby ensure, e.g., that the quantity per unit area is always the same in a curve formation even though each outlet travels a different radius.

If, in the case of non-rectangular field geometries, rows overlap or the machine encounters the side of a path, the individual outlets can be automatically switched off and then switched back on again later. Here, the dynamics of the motor are essential. It must reach the precisely specified speed with practically no time delay and deliver a high torque."

This power comes from an extremely compact drive with a diameter of just 42 millimeters and length of 49 millimeters including gearhead, all fitted in robust steel and aluminum housings. The unit can thus withstand the unavoidable mechanical vibrations that occur in agriculture. They can even handle weather extremes without problem: The temperature range spans from minus 10 to plus 60 degrees Celsius.

Taking variable soil quality into consideration

The MultiRate dosing system driven by the FAULHABER motor enables "precision farming" in the true sense of the word. The tracks – i.e., the marks left by the tractor wheels – are excluded from fertilization as are small biotopes or other non-agricultural areas that may be located in the middle of fields. Furthermore, the fertilizer quantity can also be precisely adapted to different soils within a field. "The soil quality is recorded in detail in digital application maps," explains Maximilian Zimmer. "Using such maps and GPS data, the machine control can adapt fertilizer application to the circumstances fully automatically."

In addition to the fertilizer, the Aero fertilizer spreaders can also be used to plant intercrops, such as rapeseed or mustard grass. These bind nutrients, protect the soil and contribute to its improvement. The quality of the fertilizer granulate plays a less significant role than with disk spreaders: The machine can dose precisely and can accurately apply the fertilizer even if there is a high percentage of breakage and dust.

Maximilian Zimmer summarizes: "This precision technology not only protects the environment and – in particular – the groundwater, it also lowers costs. The farm has a higher yield with less fertilizer. And, with a lower granulate quality, the cost of the fertilizer may be significantly lower."

The Aero fertilizer spreader was awarded the Environmental Technology Prize (Umwelttechnikpreis) in the category of Measurement and Control Technology, Industry 4.0, by the State of Baden-Wuerttemberg in November 2021.

Products