What do big future trends mean for small drives?

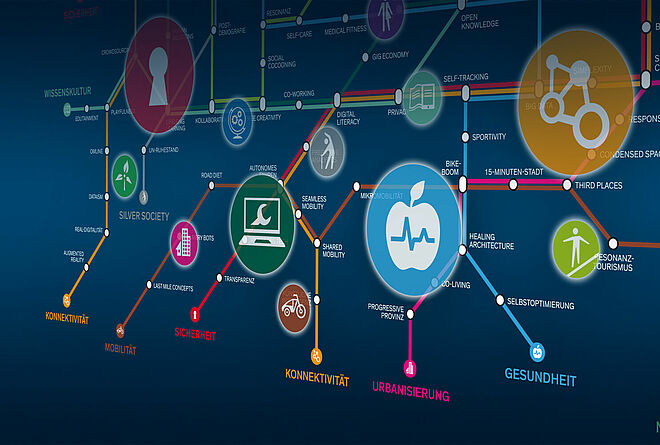

Future trends describe the changes and developments in all areas of society, the economy or technology that triggers a new movement or direction. Futurology analyzes these and uses certain boundary conditions to allow statements to be made about the future development. Among current...