Quakes are a sure sign of the movement of masses below a planet's surface. This realisation is actually quite recent in the world of natural sciences. Around 100 years ago, the German geoscientist Alfred Wegener proposed the theory of plate tectonics – a theory which was initially ridiculed by colleagues. Today, our understanding of continental plates, which float and shift on the Earth's molten mantel, is routinely taught in schools. Deep rift valleys and high ridges: the movement of continental plates alters geological formations. This is known to happen on Earth. But what about on our planetary neighbour Mars?

More sensitive than any other device

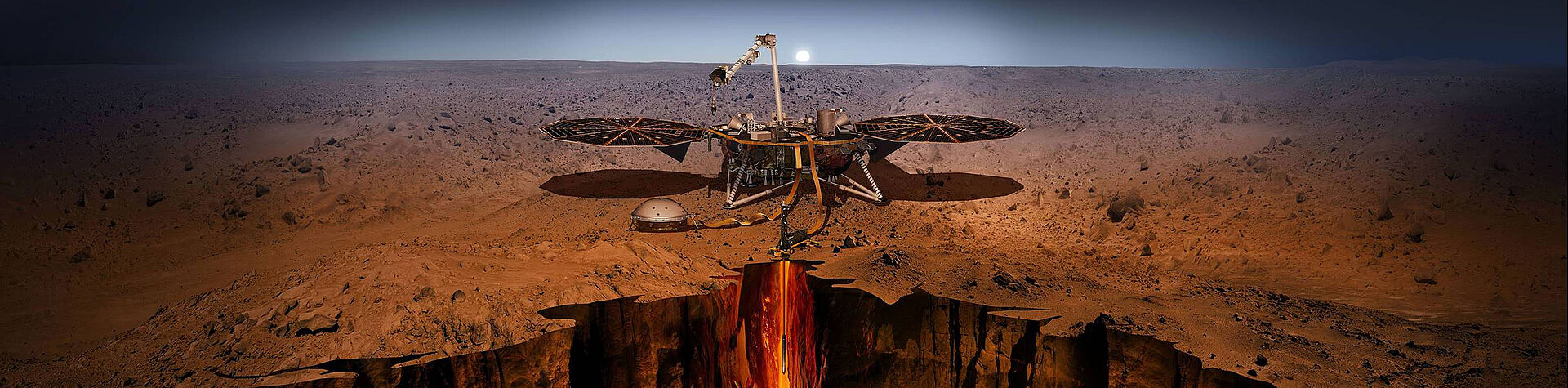

The Upper Rhine Plain in Germany stretches over a length of around 400 kilometres. The Valles Marineris on Mars is ten times as long and at some points is seven kilometres deep. Was the canyon on our neighbouring planet also formed as a result of plates shifting on the planet's crust? And: did this process end long ago, or is it still continuing today? These questions can be answered by measuring seismic waves. Is there seismic activity on Mars? NASA's "InSight" mission, which was launched on 5th May 2018, should provide an answer to this and other questions. The lander will touch down on Mars at the end of November and, using its robot arm, will place a seismometer on the planet's surface. The measuring instrument called SEIS is so sensitive that it can detect subsurface displacement corresponding to the diameter of a single hydrogen atom. NASA refers to this instrument as "the most sensitive seismometer that was ever built."

Compensating for material expansion

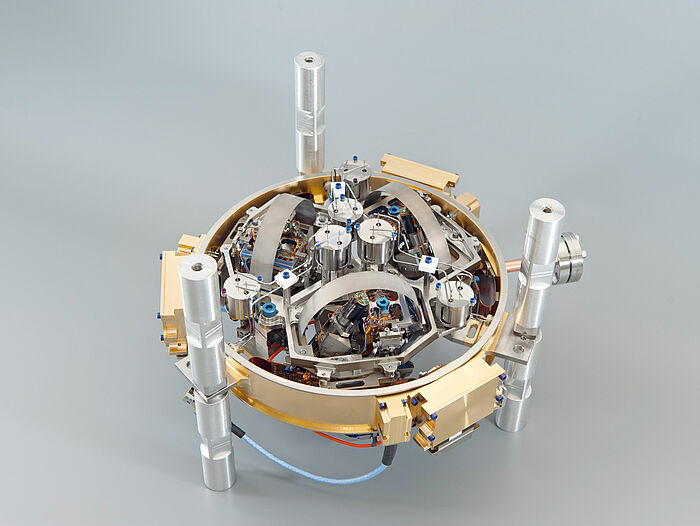

The sensitivity and measuring accuracy are, among other things, the result of the thermal balancing of a spring mechanism. This balancing is necessary because the different seasons on the Red Planet cause great fluctuations in temperature. And what applies on Earth equally applies on Mars: different temperatures cause materials to contract and expand and also have an effect on their strength – an aspect that is particularly noticeable in spring mechanisms. Three type AM 0820 stepper motors from FAULHABER are installed inside the vacuum chamber of SEIS in order to offset these changes in temperature. The motors with a diameter of just eight millimetres are combined with 08/1 series planetary gearheads from FAULHABER. With their stainless steel housing the gearheads are equipped with a special shaft and a specially coated ball bearing for their use on Mars.

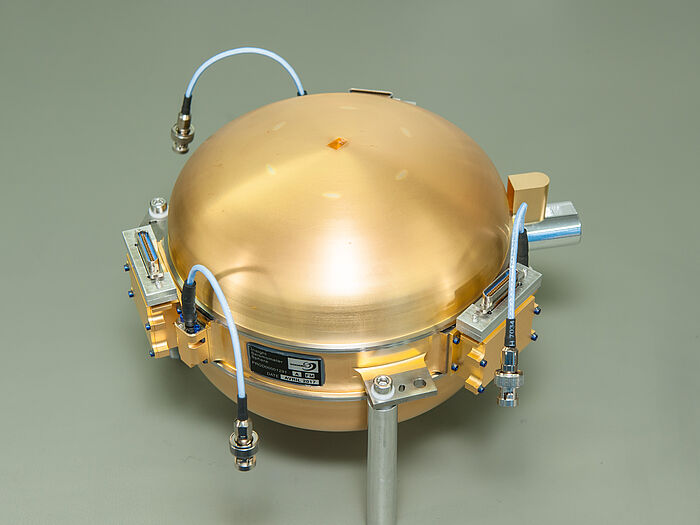

The seismometer was built primarily by Sodern – a subsidiary of the French Ariane group. When evaluating the drive technology, Sodern sought the best technical equipment. "This required painstaking research," recalls press spokesman Rémy Lambertin. After all, his company was about to "build one of the smallest instruments that we have ever sent to Mars." And the smaller an instrument is, the more fragile it will be. Consequently, the bar was set extremely high with respect to aspects such as robustness, durability and operational reliability.

The stepper motor drive solution designed jointly with the French FAULHABER subsidiary is expected to perform at least 160 correction cycles over a period of two years. The endurance tests carried out on Earth were, however, designed to simulate six years – and this in a thermal operating range of -120 to +70 degrees Celsius. FAULHABER stepper motors have already been used successfully under such demanding ambient conditions on other NASA and ESA Mars missions.

Well lubricated – a real challenge

According to Rémy Lambertin, one of the greatest challenges associated with use of the seismometer was ensuring that the drive technology was lubricated effectively. A special lubricant is necessary because the average pressure on the surface of Mars is only 6.36 hPa. On Earth, this roughly corresponds to the air pressure at an altitude of 35 kilometres. Reliable lubrication of the motors' ball bearings as well as the gearheads' sliding parts is provided by Dicronite and is one of the crucial factors enabling SEIS to be adjusted with zero backlash and exceptional durability on the Martian surface.

SEIS – Seismic Experiment for Interior Structure – essentially consists of two triaxial seismological sensors that detect ground motion of different intensity and frequency. One sensor measures frequencies of 0.01 to 10 hertz, and the other frequencies of 0.1 to 50 hertz. SEIS is supported by instruments that measure wind strength, air pressure, temperature and magnetic field. The objective of these measurements is to find out whether vibrations really are of seismic origin or simply the result of disruptive factors on the surface of Mars. In all, the instrument is able to detect vibrations that shift the ground of the Red Planet by less than the thickness of a hydrogen atom. This degree of precision is only possible because the positioning system driven electrically using FAULHABER stepper motors performs an elaborate levelling process. Incidentally, the system was developed in Germany at the Max Planck Institute for Solar System Research in Göttingen.

Backlash-free microdrives

After the landing in November, the drive axes will work with a positioning accuracy that has a tolerance of less than 0.1 degrees. The zero backlash of the six FAULHABER drive axes ensures the consistently high repeatability of travel – and this with a net mass of less than 20 grams. This huge technological effort is necessary because SEIS is alone on Mars. In contrast, seismometers on Earth are usually part of a network – which ultimately improves measuring precision. With this in mind, the highly sensitive seismometer on the Red Planet is housed in a thermally insulated vacuum box which is intended to protect against disruptive environmental factors.

Products