Man flies to the moon and sends probes to the edge of the solar system and beyond. However, man can only penetrate a few thousand metres into the earth. In order to explore the interior of the planet, we are therefore dependent on indirect methods. Seismology – from the Greek seismós, meaning earth tremors – researches the vibrations which are caused by the movements of the continental plates. Conclusions are drawn about what is happening in the earth's interior from their spread, just like using ultrasound to view a baby. A "proper" earthquake that can be felt without instruments is relatively easy to measure. The vibrations are intense and the signal is appropriately clear and can also be recorded by less sensitive sensors.

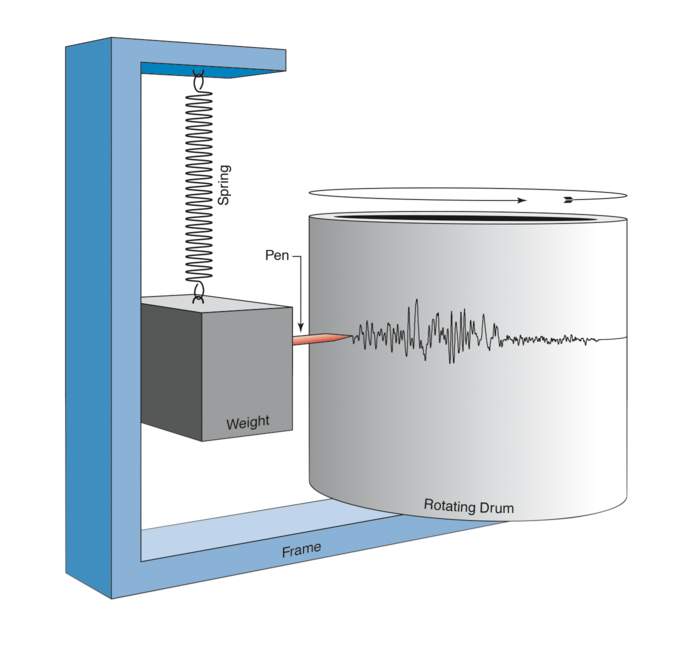

It is more difficult when the movements are very small, such as the washing of the ocean waves, which is present as micro-seismatics all over the world. The simple traditional seismometer has no chance in this case. It basically consists of a weight – the pendulum –, which is suspended from a spring. A pin is attached onto the weight which draws curves onto a continuous roll of paper when the vibrations occur. The deflection indicates the strength of the vibrations – but only as far as edges of the paper roll. At the other end, the sensitivity is limited by the thickness of the pin: minimal deflection of less than the line width is no longer clearly recognisable. This corresponds to dynamics of approx. 60 dB.

A sheet of paper 18 kilometres wide

In order to overcome such limitations, prospective geophysicist Gunar Streckeisen developed the so-called STS-1 broadband seismometer at the ETH in Zurich during the course of his dissertation and under the guidance of Erhard Wielandt about 35 years ago. He later founded Streckeisen AG in Winterthur in order to manufacture these devices and distribute them all over the world. This meant the end of road for classic seismometers. Erhard Wielandt was the driving force in the development of modern seismic measuring technology at this time.

The pendulum remains in the balanced equilibrium position

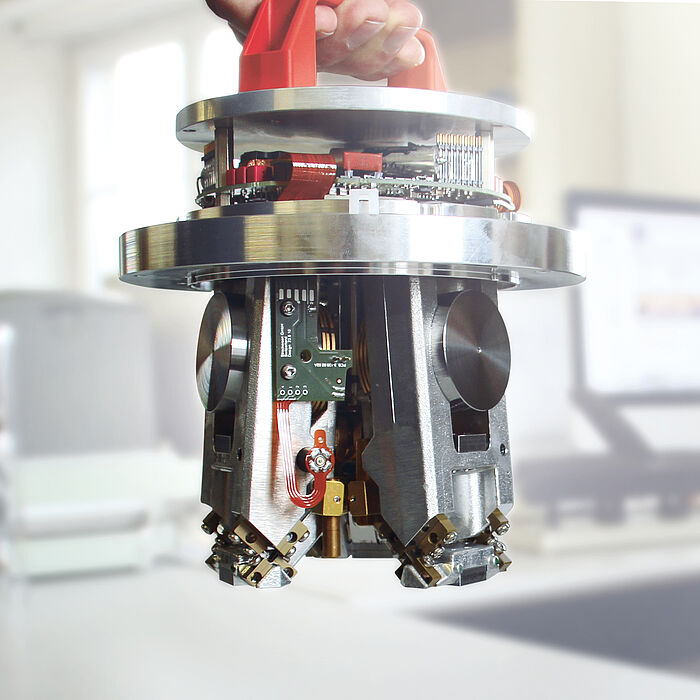

The only thing that a broadband seismometer has in common with its classic predecessor is the moving pendulum, which reacts to outside forces. A pin is no longer needed, particularly since a straight line would always be drawn. The trick with which the Streckeisen seismometer achieves its extremely large dynamics lies in the tracking: an electromagnetic feedback system ensures that the pendulum always remains in the established, balanced equilibrium position. "It works like an electronic balance", explains Robert Freudenmann, managing director of Streckeisen. "The correction signal that is needed for tracking is also the output signal at the same time. The more powerful the movement acting upon the device the greater the signal, and the pendulum therefore always remains in the middle.” 145 dB can be achieved using a measuring principle such as this, which corresponds to an 18 km wide sheet.

In order to record the movements of the earth in all three dimensions; each seismometer has three pendulums. They are in a slightly tilted position, arranged in a circle, each offset by 120 degrees. They react differently depending on the direction of the force, and the three-dimensional image of the spacial variations can be calculated from the differences.

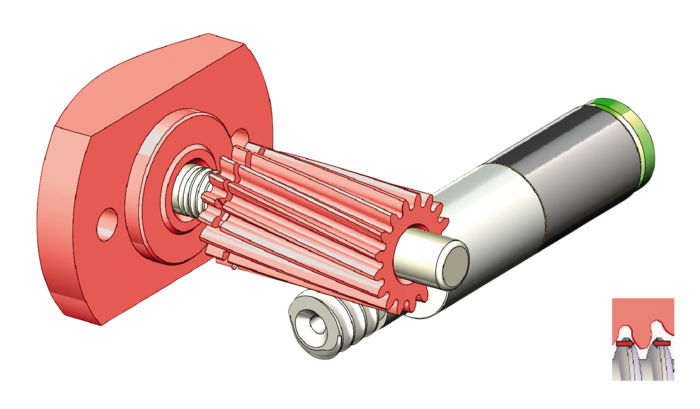

Balancing once in ten years

Once installed, the high-precision electromechanics work automatically and can go without human intervention for a long period. Exact alignment of the seismometer and balancing of the pendulum are crucial before starting operation. "Traditionally, seismometers have always been aligned eastwards", explains Robert Freudenmann. "In order to balance the pendulums, a moving mass on the pendulums is moved until they are perfectly balanced. The mass is a toothed ring, which is moved to and fro by rotating on an axis. It is driven by a screw that is positioned at right angles to it. There is a small amount of play in the toothed ring and the screw. When perfect equilibrium is reached, the tooth of the adjusting weight remains between the tooth flanks of the screw, i.e. the pendulum can be moved freely."

Long-term reliability

This process, which is known as "centring" within expert groups, is carried out by an AM0820 stepper motor with 16:1 planetary gearheads from FAULHABER. It must fulfil a wide range of requirements of the high-quality application: small dimensions and current consumption; precise movement and insensitivity to low temperatures, since Streckeisen devices are also used in Northern Alaska and near the South Pole. But the most important thing is longterm reliability: "For long-term measurements, a location is chosen which the ambient conditions are very stable", explains Robert Freudenmann. "In extreme cases, the pendulum is balanced for the first time before being put into operation, and the second time may only occur ten years later. Then the motor immediately has to perform its task again with precision, even after a long period of inactivity. We know that FAULHABER motors are capable of this."

Inflated concrete chamber

Not all devices are used for long-term measurements. In so-called array measurements, a large number of seismometers are arranged in a grid formation in a certain area in order to record the special features of the subsoil in this location. Once the measurements are complete after several months or a few years, the grid is moved and the devices travel to their next location. For example, the states of the USA are measured one after the other in this way. However, the unavoidable movement that takes place during transport is not good for the sensitive sensors. In order to prevent damage, the moving parts are therefore secured with a transportation lock. This is carried out by the fourth motor in the Streckeisen seismometer, a 0816P006S DC-micromotor. "FAULHABER can provide us with both steppermotors and also micromotors with the right and with outstanding quality in a practical way", emphasises Robert Freudenmann.

Modern seismometers from Streckeisen are smaller and easier to set up than the first generation. A new variant with a tubular housing can be lowered into boreholes. The installation is still carried out by means of delicate manual work. It cannot be checked whether the components interact with the necessary accuracy until right at the end. Every sensor is therefore subjected to extensive testing in an air-raid shelter for insensitivity to air pressure fluctuations, amongst other things. A ventilator blows air into the chamber, which is surrounded by thick concrete, and "inflates" it. "Its hard to believe, but the increased air pressure actually alters the room, even though it is only by a few nanometres", explains Robert Freudenmann. "Our devices can detect this change. If a device was not sealed, we would receive a deviating signal. Using tests such as this, we ensure that only perfectly functioning seismometers are delivered that precisely record what is going on in the earth's interior.

Products