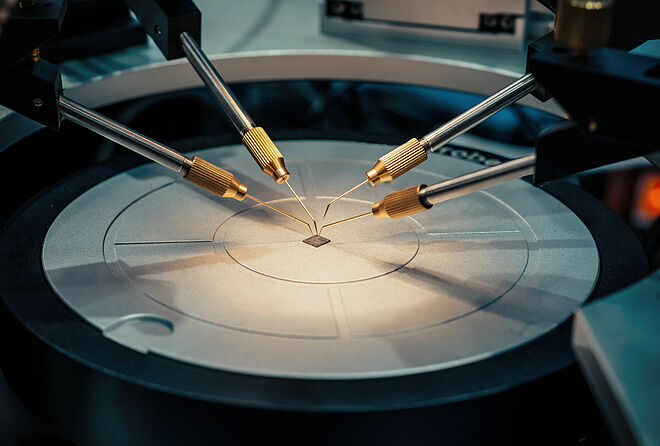

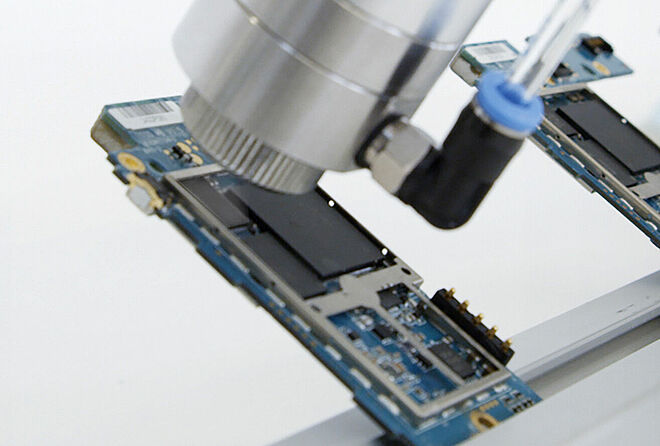

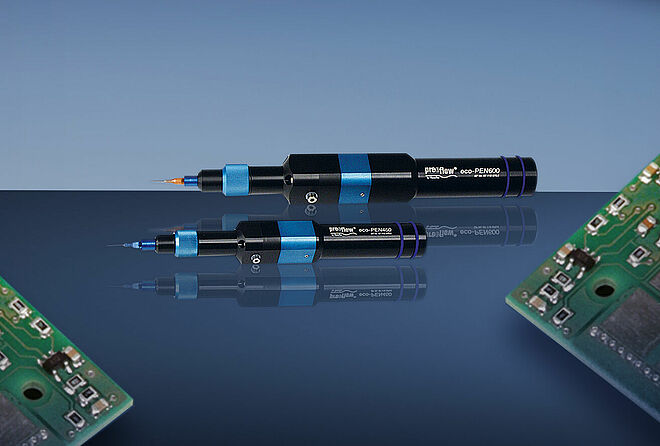

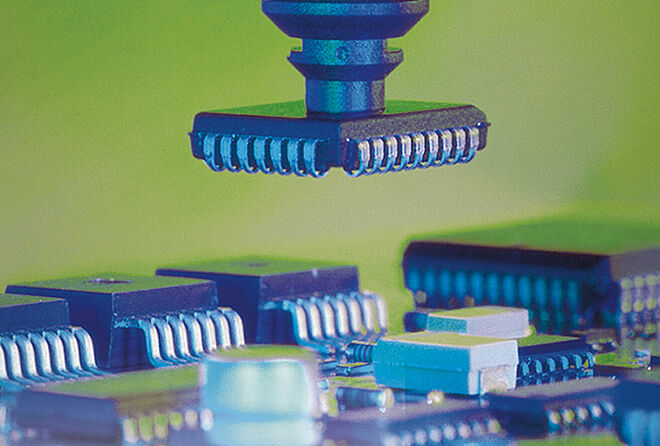

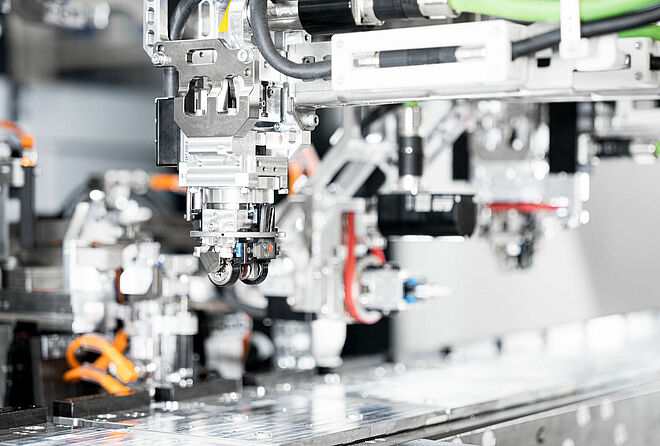

L'«automazione compatta» è un sistema meccatronico che esegue in modo autonomo tutta una serie serie di passaggi produttivi consecutivi. Il termine «compatto» si riferisce alle piccole dimensioni, nell’ordine del millimetro e del centimetro, dei prodotti da lavorare. La progettazione...