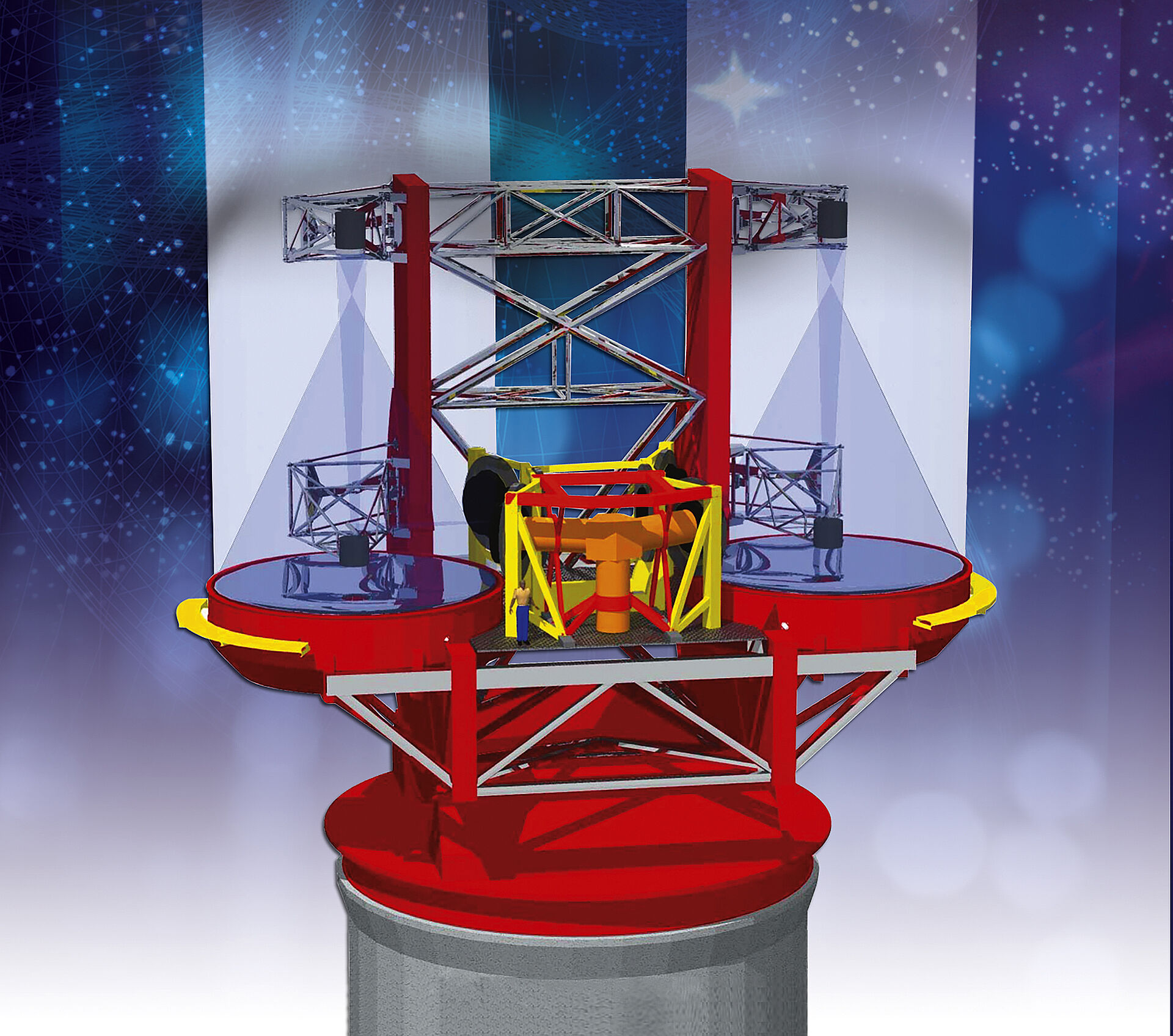

In 2004 wordt in de Amerikaanse staat Arizona de grootste onafhankelijke telescoop ter wereld in gebruik genomen op Mount Graham.

De astronomen zijn met name geïnteresseerd in beelden van afgelegen melkwegstelsels, jonge dubbele sterren en sterren die net ontstaan zijn. De Large Binocular Telescope (LBT) is ruim 20 meter hoog en weegt meer dan 600 ton. Het werkingsprincipe is echter hetzelfde als dat van een verrekijker. De twee reflectoren hebben allebei een diameter van 8,4 m en vormen samen een schotel van ongeveer 100 vierkante meter om licht op te vangen. Hiermee kan de LBT zelfs straling van zwak verlichte objecten opvangen, die zich aan het uiteinde van het observatiebereik bevinden. De samenwerking tussen de twee reflectoren die op 14,4 meter van elkaar staan, geeft de telescoop een resolutie die overeenkomt met die van een verrekijker met een diameter van 23 meter. De reflectoren zijn gemaakt van boriumsilicaat en lijken op een reusachtige honingraat met een gewicht van 15,6 ton.

Interferentie als sleutel voor hogere beeldresoluties

Het ontwerp van de telescoop en de ingebouwde optische systemen bieden wetenschappers ongekende flexibiliteit voor hun observaties. Ze kunnen de reflectoren onafhankelijk van elkaar gebruiken om hetzelfde object te bekijken, maar ook verschillende objecten bestuderen door de assen licht te kantelen, of observaties van één object verbeteren door beide reflectoren te combineren voor een maximale resolutie. Een natuurkundig trucje helpt hierbij: de lichtstralen die door iedere reflector worden weerspiegeld, worden over elkaar gelegd om interferentie te creëren en zo een uitzonderlijk hoge resolutie te behalen.

In vergelijking met een conventionele enkele telescoop is de resolutie ongeveer tien keer hoger. Om ervoor te zorgen dat de LBT goed werkt, moeten alle individuele componenten uit verschillende landen – de Verenigde Staten, Italië en Duitsland – probleemloos samenwerken. Daarbij zijn de bedrijfsomstandigheden op locatie ongunstig: Mount Graham is ongeveer 3300 meter hoog. Op die hoogte liggen de temperaturen vaak onder nul, bij een hoge luchtvochtigheid van wel 90%. Ook zijn er extreme temperatuurschommelingen.

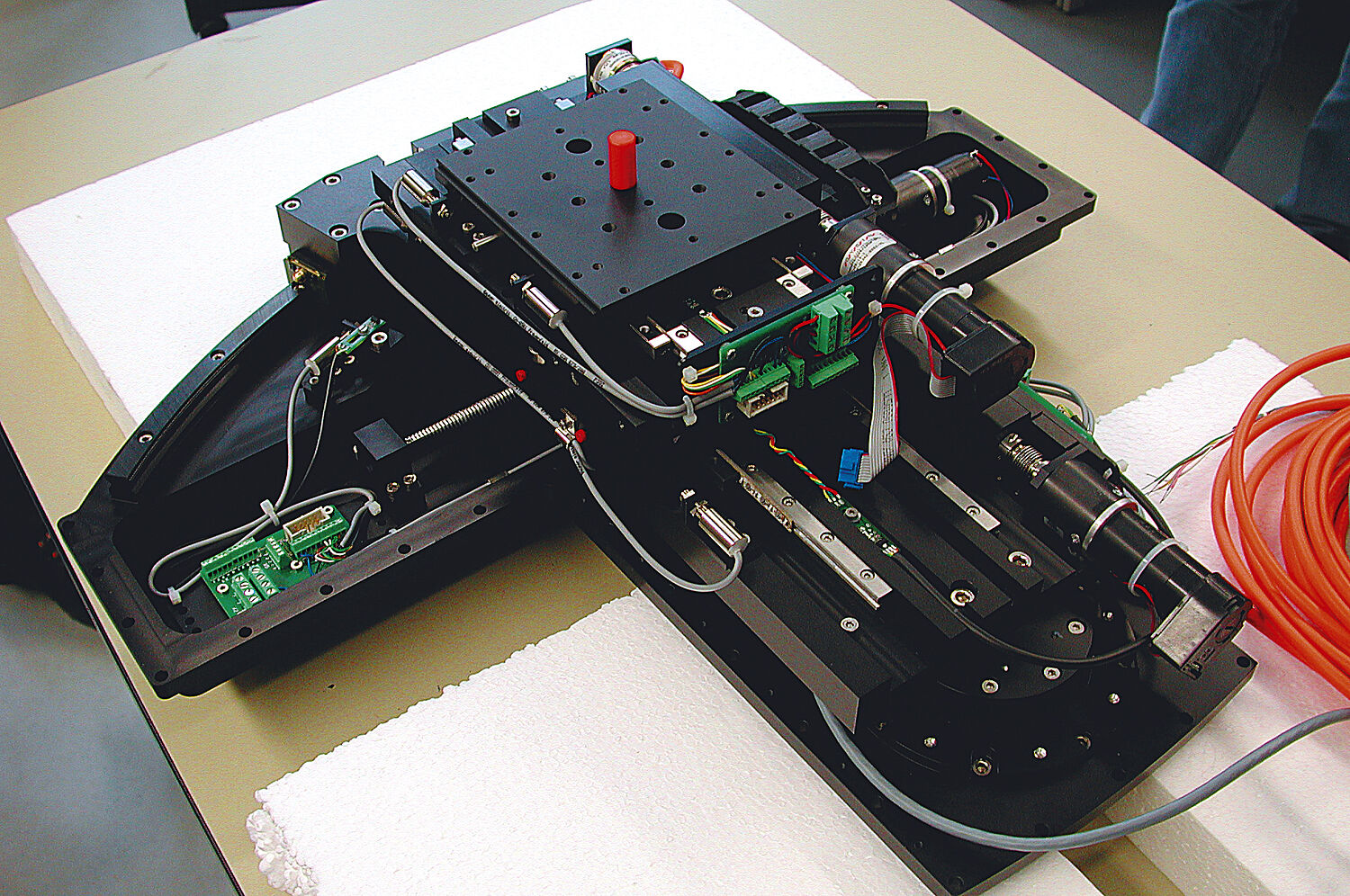

Positioneringseenheid om interferentie te creëren

Om een beeld met hoge resolutie te behalen door interferentie te genereren, moeten de optische componenten van de twee reflectoren het weerkaatste licht bundelen en de bundels over elkaar heen leggen. De vereiste nauwkeurigheid voor de positionering is hierbij 5 µm. Voor deze toepassing heeft het Duitse bedrijf Feinmess in Dresden een drieassig positioneringssysteem ontwikkeld dat het betreffende optische systeem op de twee reflectoren van de LBT naar de juiste positie beweegt. Horizontaal moet het systeem afstanden tot 200 mm overbruggen (longitudinale positionering) en verticaal, voor de scherpstelling, tot 50 mm. Tegelijkertijd moet de optische module tot een hoek van 36 graden geroteerd worden. Om de vereiste positioneringsnauwkeurigheid te garanderen, moet de speling binnen het systeem tot een minimum beperkt blijven. Daarom wordt grote waarde gehecht aan de aandrijvingen op de spindels.

Voor deze toepassing is gekozen voor aandrijvingen van FAULHABER. De traditionele klokankermotor met kernloze rotorspoel vormt een uitstekend uitgangspunt voor dit soort toepassingsgebieden. De kleine DC-aandrijvingen werken ook onder zware bedrijfsomstandigheden betrouwbaar. Ze zijn bestand tegen temperaturen van -30° C tot +125° C en met de juiste specificaties is ook een hoge luchtvochtigheid tot wel 98% geen probleem. Een belangrijke basisvereiste bij de selectie van de DC-motoren was ook een directe start met een hoog koppel, nadat ze onder spanning zijn gezet. Dit garandeert dat de motoren onmiddellijk reageren op de signalen van de besturing. De kernloze koperspoel ondersteunt een bijzonder lichtgewicht motorontwerp met een hoog rendement tot 80%. De motoren voor alle drie de spindels van het positioneringssysteem hebben een diameter van 26 mm en een lengte van slechts 42 mm. Bij toerentallen tot 6000 t.p.m. leveren ze een uitgangsvermogen van 23,2 W.

Motor, tandwielkast en pulsencoder als compacte eenheid

In de LBT-telescoop zijn de motoren gecombineerd met planetaire tweetraps tandwielkasten met een ratio van 16:1. Ze zijn aan het uiteinde van de motor geflensd en leveren indrukwekkende prestaties, niet alleen met hun compacte formaat maar ook met hun constante bedrijf en stevigheid. De speling van de tandwielkasten is geoptimaliseerd voor gebruik in het positioneringssysteem. Bij standaard planetaire tandwielkasten is een waarde van ongeveer 1 graad gebruikelijk, maar deze modellen hebben een speling van slechts 12 boogminuten, gemeten aan de uitgangsas.

Voor een consequent nauwkeurige positionering moet de huidige motorpositie steeds bekend zijn. De positioneringssystemen van de LBT werken hiervoor met optische pulsencoders bij iedere motor, die 500 pulsen per omwenteling genereren. Met behulp van een metalen schijf genereert het systeem met uitgezonden licht tweefase kwadratuur uitgangssignalen. De indexpuls is gesynchroniseerd met uitgang B. Voor alle drie de kanalen zijn er geïnverteerde, aanvullende signalen. De pulsencoder wordt bevestigd aan het vrije uiteinde van de motoras en met drie schroeven vastgezet. De voedingsspanning voor de pulsencoder, de miniatuur-DC-motor en de uitgangssignalen loopt via een bandkabel en een 10-pins connector. Omdat de aandrijvingen met motor, tandwielkast en encoder bijzonder compact zijn, kunnen ze eenvoudig worden geïntegreerd in het drieassige positioneringssysteem. Miniatuurtechnologie voor motion control speelt dus een essentiële rol om ervoor te zorgen dat de LBT een nieuwe dimensie binnen astronomisch onderzoek opent.

Producten