Sensorcomponenten zijn inmiddels een bulkproduct. Maar het is alleen mogelijk om ze op een kosteneffectieve manier te produceren, als het proces bijna volledig automatisch werkt. Veel van dit soort massaproducten vervullen kritische veiligheidsfuncties, bijvoorbeeld als ABS-sensoren, versnellingssensoren en nog veel meer. Daarom zijn compromissen aan de kwaliteit geen optie. Tot voor kort werd de siliciumwafer handmatig in de drager gelegd en vastgeklemd. Alleen correct geplaatste wafers kunnen in de daaropvolgende processtap correct geëtst worden. Op dit punt in het fabricageproces hebben de wafers al een aanzienlijke waarde en dat vraagt om een bijzonder zorgvuldige hantering. Diensten voor 24-uurs continubedrijf verhogen de algehele productiekosten nog verder.

Kwaliteit boven alles

INGENIA heeft kwaliteit als basisprincipe. Het bedrijf is gespecialiseerd in hanteringssystemen en heeft een automatisch montagesysteem ontworpen, specifiek voor chipfabrikanten. INGENIA biedt oplossingen voor de belangrijkste problemen rondom aangepaste productieprocessen en zijn aanbod is op maat gemaakt voor de specifieke vereisten van klanten. Er gelden strenge vereisten voor hanteringssystemen: ze moeten niet alleen 24 uur per dag kunnen werken, maar de gebruikte apparatuur moet ook de nauwkeurigheid en exacte positionering op de lange termijn garanderen. Om de dure siliciumwafers optimaal te etsen, moet de wafer extreem nauwkeurig in de houder geplaatst worden en vervolgens worden vastgeklemd voor de verdere verwerking.

Dit is al een uitdaging voor standaard chips, maar voor sensoren of micromechanische chips zijn de vereisten voor de hantering zelfs nog hoger. In tegenstelling tot standaard geheugenchips of CPU's vragen deze eindproducten namelijk om tweezijdige bewerkingen van de wafer. Alleen dan kan de ingewikkelde structuur van de mechanische elementen optimaal worden gecombineerd met de benodigde elektronica. De chipfabriek heeft bovendien geen aandrijvingsspecialisten in dienst, of experts voor hanteringssystemen. De installatie en het systeemonderhoud moeten dus zo eenvoudig mogelijk worden gehouden. Het doel is om aanpassingen en optimalisatie mogelijk te maken tijdens het lopend bedrijf, of dat het systeem na onderbrekingen weer probleemloos kan opstarten. Daarnaast verlaagt een eenvoudige hantering ook de exploitatiekosten van een systeem.

Betrouwbare plaatsing

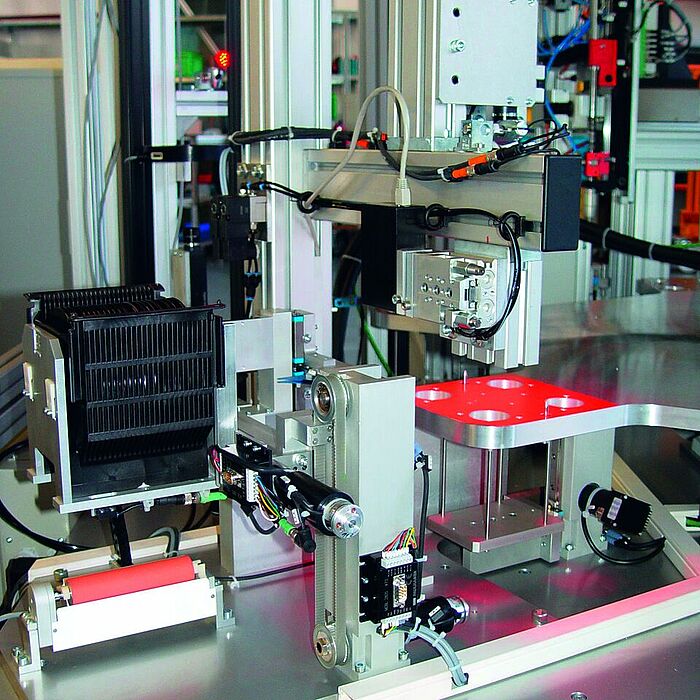

Het is een kernthema in de automatisering in ieder werkveld: hoe bouwen ontwerpers veelzijdige, aanpasbare productieapparatuur? Voor de optimale hantering werken ze met een mix van standaard componenten en speciale oplossingen. Het apparaat zelf is verantwoordelijk voor de hantering van een volledig scala aan processen: van het plaatsen van de wafers tot aan het monteren van het dragende frame en het transport van dit frame. Alle montagestappen worden op hetzelfde niveau uitgevoerd.

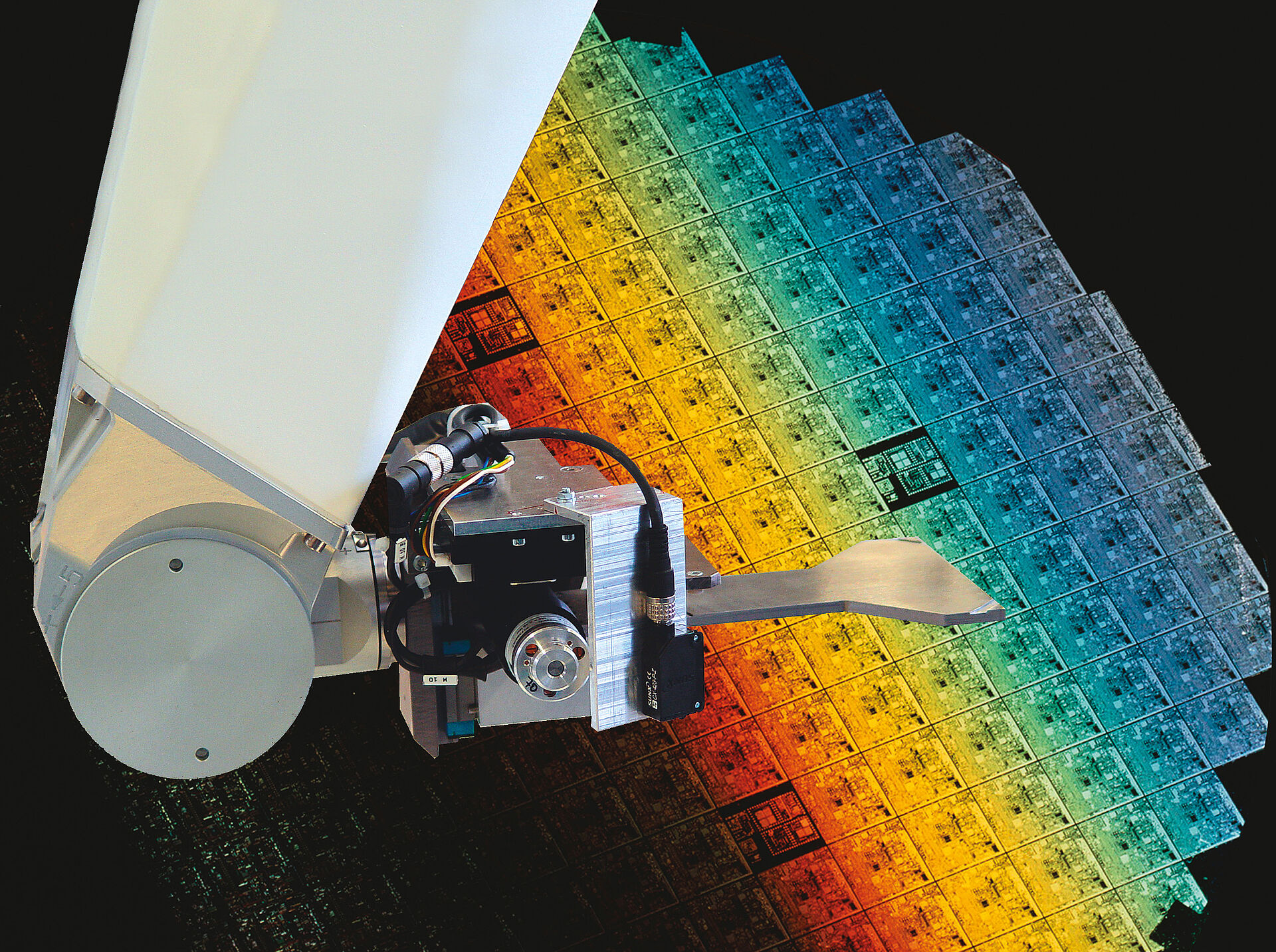

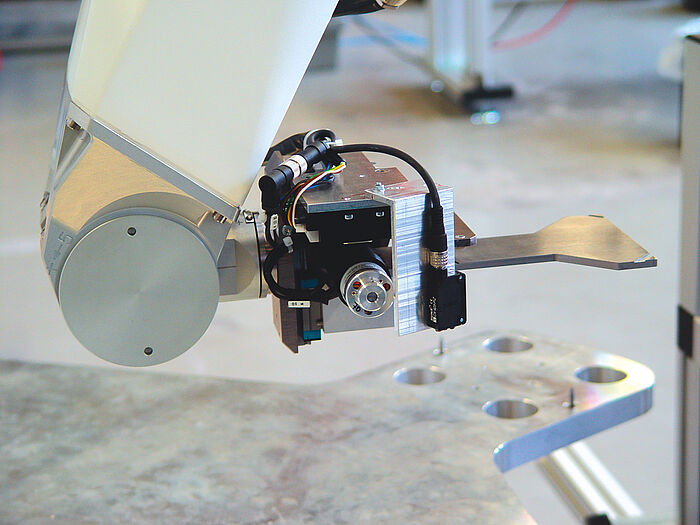

Robotarmen plaatsen de wafers en slaan de wafer in zijn doos op. Dit zijn machinecomponenten waar het hele bedrijf van afhangt. Om betrouwbaarheid en exacte positionering te garanderen, en CE-conformiteit bij stroomuitval, worden motoren met ingebouwde remmen gebruikt. De hoge basiscyclus die standaard is bij de productie van elektronica vraagt om aandrijvingen met krachtige prestaties en een hoog koppel. En ondanks de hoge dynamiek moet de positionering perfect zijn – zonder uitzonderingen. Voor het daadwerkelijke plaatsen en vastklemmen van de wafer in de houder is niet bijzonder veel kracht vereist, maar de vereisten zijn net zo hoog bij de positionering. Ten slotte moet de wafer perfect in het midden liggen, zodat het oppervlak zo optimaal mogelijk kan worden gebruikt. En de schroeven van het frame moeten niet alleen op exact de juiste positie worden ingedraaid, maar ze moeten ook identiek worden gedraaid. Alleen dan kan het systeem afwijkingen voorkomen door verschuivingen van het frame of door scheve schroefkoppen.

Flexibele aandrijvingen

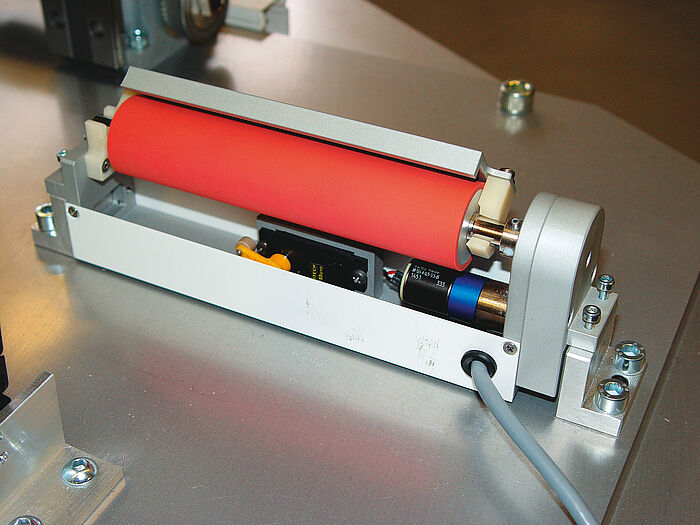

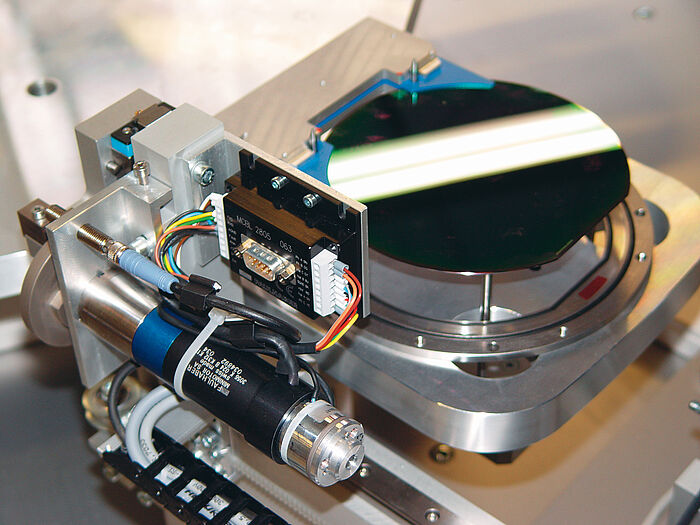

INGENIA gebruikt slijtvaste elektronisch gecommuteerde DC-motoren om aan deze strenge vereisten te voldoen. De EC-motoren van FAULHABER, specialist voor micromotoren, zijn de perfecte oplossing met een uitgebreid aanbod aan technologie voor de aansturing en de tandwielkasten. Motoren uit de productserie 3056 zijn ideaal voor machinecomponenten die bovengemiddelde eisen stellen aan toerental en koppel. De miniatuuraandrijvingen hebben een diameter van slechts 30 mm en een lengte van 56 mm, maar leveren een continu koppel van wel 21,5 mNm (blokkeerkoppel tot 100 mNm) bij een uitgangsvermogen van 49 W. De micromotoren zijn beschikbaar voor voedingsspanningen van 12, 24, 36 en 48 V DC. Met optionele tandwielkasten uit de serie 30/1 of 38/1 kan het toerental worden aangepast. De dynamische kleine krachtpatsers kunnen worden aangestuurd via de analoge Hall-sensoren van de micromotor en de motion controller MCBL 2805 die specifiek is ontworpen voor deze geavanceerde productreeks. De grotere motoren van de serie 3564 zijn ook leverbaar met geïntegreerde motion controllers. Zo ontstaat een bijzonder compacte aandrijving die inclusief controller maar 83 mm lang is bij een diameter van 35 mm. Ondanks dit compacte formaat levert deze EC-micromotor een uitgangsvermogen van 70 W en een piekkoppel van 160 mNm (continu koppel 50 mNm). Ook voor deze motor zijn passende tandwielkasten beschikbaar om het toerental en koppel aan te passen aan de vereisten.

In het model 3564 K 024 BC is de elektronisch gecommuteerde servomotor gecombineerd met een encoder met hoge resolutie en programmeerbare motion controller, met een krachtige 16 bits controller. Het toerental is regelbaar van 10 tot 10.000 t.p.m. en er zijn toerentalprofielen mogelijk met geleidelijke versnelling en trapezoïde of positioneerbewegingen met resoluties tot 1/1000e omwenteling. Controles voor referentiemarkeringen en limietschakelaars zijn ook mogelijk. De aandrijvingen zijn voorzien van een ingebouwde bescherming tegen oververhitting, overbelasting of overspanning bij gebruik met een generator. Naast autonome implementaties is ook een extern aangestuurd bedrijf mogelijk via een RS232-interface. Met adressering kunnen meerdere motoren via één interface worden aangestuurd. Speciaal hiervoor is een multiplexer-board verkrijgbaar.

De combinatie van flexibele aandrijfconcepten en vernieuwende systeemoplossingen biedt ook een goede basis om productiekosten voor elektronica omlaag te brengen, terwijl de productkwaliteit tegelijkertijd stijgt. Geavanceerde aandrijvingen zorgen op ieder moment voor snelle en nauwkeurige hantering.