Siemens heeft zijn geavanceerde SIPLACE X Series ontworpen met een duidelijk doel: wereldwijde elektronicafabrikanten moeten met deze machine nog kostenefficiënter in staat zijn om printplaten te produceren. De X Series bevestigt tot 80.000 componenten per uur en hanteert 01005-componenten van 0,4 x 0,2 mm tot aan componenten van 6 x 6 mm. Daarnaast besteedden de ontwerpers veel aandacht aan snelle wissels. Net als bij alle machines met geavanceerde mechanica, was ook hier de aandrijftechniek van doorslaggevend belang voor een succesvol design.

Het ontwerpteam van de SIPLACE X Series werkte samen met de specialisten voor microaandrijvingen van FAULHABER om de best mogelijke expertise in huis te halen voor deze uitdaging. De nauwe samenwerking vormde een uitstekende basis voor een stroomlijning van de componenten in de X Series. Het resultaat: direct in de eerste ontwerpfase kon het team al eersteklas oplossingen ontwikkelen. Met deze benadering bouwde Siemens een high-performance montagemachine voor het premiumsegment, die nieuwe standaarden bepaalt voor de montage van printplaten.

Basisprincipes

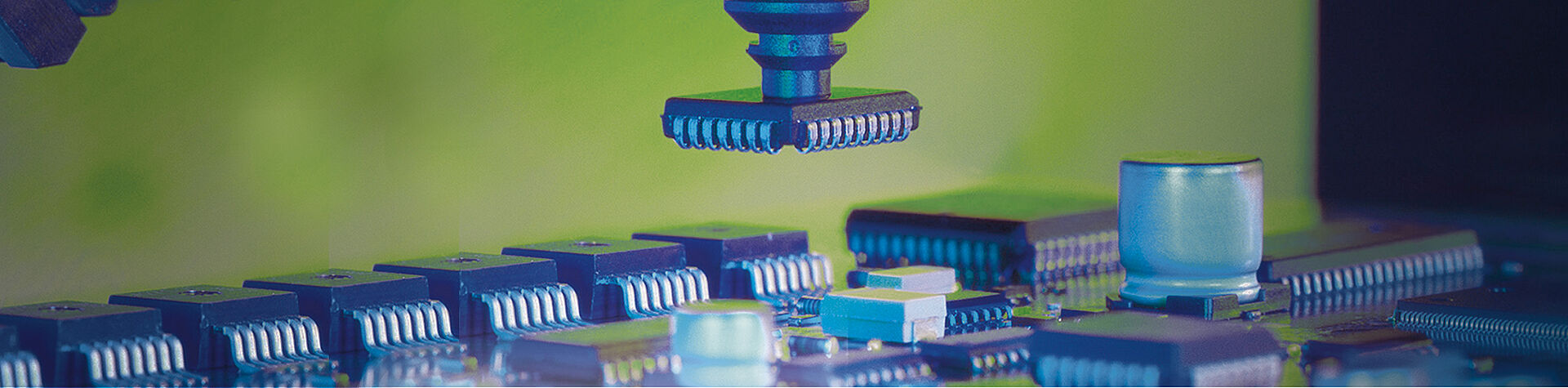

Een montagemachine bestaat uit onafhankelijke onderdelen, die allemaal synchroon moeten samenwerken. Een positioneerkop op een mobiel portaal verzamelt de printplaatcomponenten van de aanvoerband en transporteert ze naar hun montagepositie op de printplaat om ze hier nauwkeurig op de juiste plaats te bevestigen. De stap tussen het verzamelen van de component en het positioneren van de eenheid boven de printplaat vereist tijd. Hoe sneller en minder vaak deze verplaatsing plaatsvindt, des te sneller kan de machine printplaten fabriceren.

Ook de aanvoer van de componenten is een belangrijke factor. In de huidige technologie worden de componenten aangevoerd met banden en rollen. Het principe is vergelijkbaar met dat van analoge fotorolletjes. Kleine uitsparingen in de transportband bevatten de componenten en perforaties aan de rand garanderen het nauwkeurige transport. De transportband gaat een transporteur in en verplaatst zich zo dat een component altijd precies klaar is om door de positioneerkop opgenomen te worden. Voor dit proces moet de positioneerkop exact de juiste opnamepositie en -snelheid behouden. Ook de toevoer moet continu gegarandeerd zijn, ook als er meerdere componenten achter elkaar nodig zijn van dezelfde band.

De SIPLACE Collect & Place-unit – klein ontwerp, grote prestaties

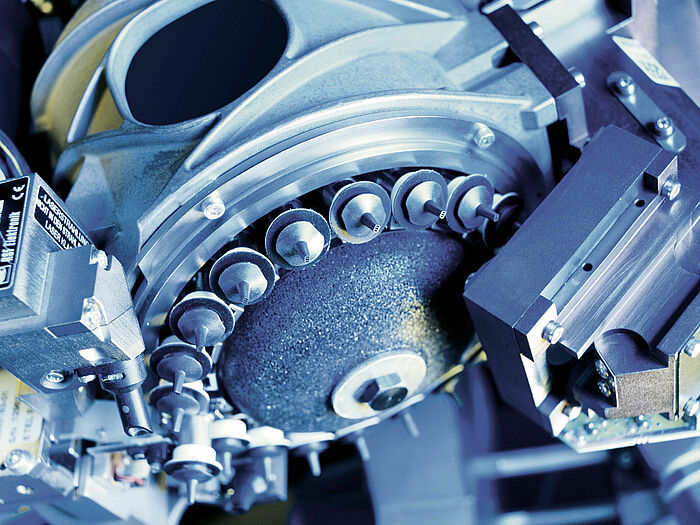

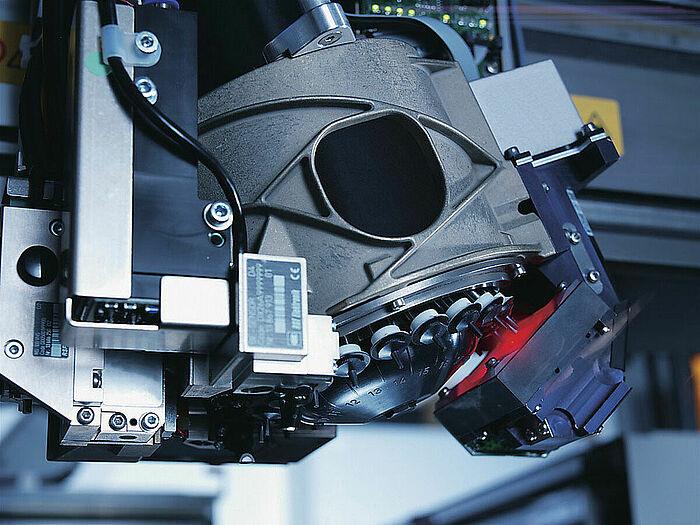

De Collect & Place-unit voor 20 segmenten vormt de kern van de machine. En juist deze eenheid bleek een bijzondere uitdaging te zijn. Aan de ene kant is het een bijzonder dynamisch onderdeel, wat licht gebouwd moet worden, dus zonder grote massatraagheid. Aan de andere kant moet de unit zoveel mogelijk componenten tegelijk kunnen opnemen. Als de unit meer componenten verwerkt per cyclus, hoeft de kop minder vaak heen en weer te gaan tussen de printplaat en de opnamepositie. Dat vertaalt zich in hogere bedrijfssnelheden. De ontwikkelaars kozen daarom voor een nieuwe Collect & Place-unit (C&P) met 20 segmenten.

De kop werkt met pipetten op onderdruk om de componenten op te pakken en vast te houden. Een camera registreert de componenten die stevig op de pipetten zitten, vergelijkt hun positie met de doelpositie en geeft een commando af aan de micromotor om de pipet in de juiste positie te draaien. De C&P-unit voor de positionering heeft 20 segmenten met 20 pipetten, die allemaal een eigen motor hebben. De kop zelf is licht conisch gevormd om zoveel mogelijk ruimte over te laten voor de componenten. Dit betekent dat er met name in het bovenste deel van de kop erg weinig plaats is. De motoren die de pipetten in de juiste positie draaien, hebben dus vrijwel geen ruimte om te manoeuvreren. Daarom was alleen een extreem gespecialiseerd motorontwerp, perfect aangepast op de beschikbare ruimte, in staat om een compacte en lichtgewicht oplossing te leveren.

De 20 borstelloze DC-motoren met een diameter van slechts 8 tot 9 mm, inclusief positiesensor, zijn hiervoor in een licht conische vorm uitgevoerd. Door hun elektronische commutatie zijn ze bijzonder geschikt voor positioneringstaken bij continubedrijf. Dit vereist echter een superieure aansturing van de aandrijvingen. Op dit punt gaf het goede partnerschap tussen de experts de doorslag. Het team gebruikte niet twee aparte controllers voor de motoren en de andere componenten in de kop, maar koos voor synergie. De controle-elektronica voor de motoren is geïntegreerd in de besturing van de overige componenten, zodat deze veel minder ruimte in beslag neemt. De besturing is hierdoor kleiner en lichter, terwijl de montageprestaties beter zijn.

Snelle en precieze aanvoer van componenten

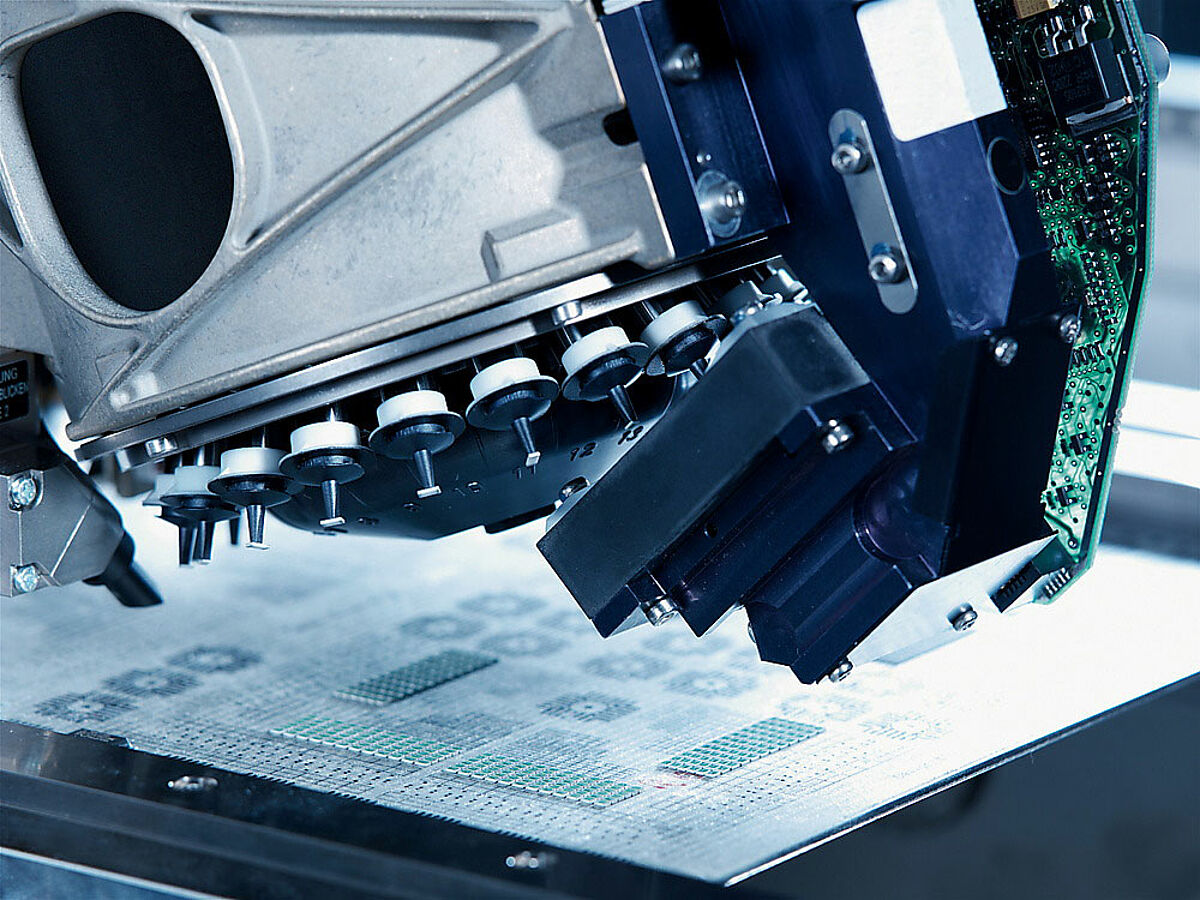

Om optimaal te profiteren van de superieure operationele performance van een C&P-kop met 20 segmenten moet ook de aanvoer van de componenten uitermate nauwkeurig werken. Naast hogere snelheden waren hiervoor ook eenvoudige wissels tijdens het bedrijf en een universele toepassing belangrijke ontwerpdoelen. Tot voor kort was de standaard aanvoermethode voor componenten een transporteur van minstens 30 mm breed, waar één, twee of drie banden op pasten (met standaard bandbreedten van 8, 12, 16 tot en met 88 mm). Bij een componentwissel moesten alle banden worden uitgewisseld met de transporteur, zelfs als er maar één andere component nodig was voor de betreffende printplaat. Om efficiënter te kunnen werken was het doel om met drie onafhankelijke transporteurs te werken – op dezelfde breedte van ongeveer 30 mm die de Triple Feeder bood. Tot nu toe werden de banden aangedreven door relatief "grote" micromotoren met een diameter van 15 mm: twee naast elkaar, en een derde verder naar achteren.

De X-Feeder moest echter alleen ruimte bieden aan motoren met een diameter van ca. 10 mm. Dankzij speciale, extra sterke magneten zijn deze nieuwe motoren in staat om dezelfde prestatieniveaus te leveren als conventionele motoren van 20 tot 25 mm. Dit is een indrukwekkend staaltje ingenieurskunst: een toename of afname van de motorprestaties hangt samen met de diameter in het kwadraat. Tegelijkertijd moet het aandrijfsysteem de tractie van de band kunnen absorberen. Over het algemeen gaat het hierbij om meerdere Newton trekkracht. Bij grotere krachten scheuren de perforaties aan de rand uit. Deze vereiste is ongebruikelijk voor kleine aandrijvingen, maar de aandrijfspecialisten van FAULHABER vonden een oplossing door voor iedere bandtransporteur twee motoren te gebruiken.

De motoren zijn schuin geplaatst op een gedeelde helische versnellingsas die op zijn beurt het tandwiel voor de bandtransporteur aandrijft. Deze aanpak garandeert op ieder moment de benodigde dynamiek en de koppelcurve tot in het veilige bereik. De aandrijving van de X-Feeder zorgt zo voor betrouwbare positionering tot op ±25 µm bij cyclustijden van minder dan 40 ms. Zo ontvangt de C&P-kop met 20 segmenten een betrouwbare toevoer van componenten.

Producten