Gli elastomeri, ossia i materiali simili a gomma, sono onnipresenti nella vita di tutti i giorni. Come altri prodotti, anche in quest’ambito si osserva una tendenza verso la realizzazione di oggetti sempre più piccoli. Finora il metodo di prova utilizzato in ottemperanza alla norma DIN 53505 prevedeva l’uso di un ago conico relativamente grande. Ora, invece, l’azienda tedesca Q-TEC GmbH, con sede a Zeilarn, è riuscita a ridimensionare geometricamente la procedura fisica, rendendo così possibile misurare sia campioni ultra-miniaturizzati, sia punti precisi di parti di prodotti più grandi. Per l’esatto posizionamento e la regolazione della forza della sonda di prova, miniaturizzata fino a un fattore dieci, l’azienda ha lavorato fianco a fianco con gli specialisti di azionamenti ultra-miniaturizzati FAULHABER. Il frutto della collaborazione è un dispositivo di misurazione compatto, capace di rispettare le specifiche standard in forma miniaturizzata.

Misurazione della durezza

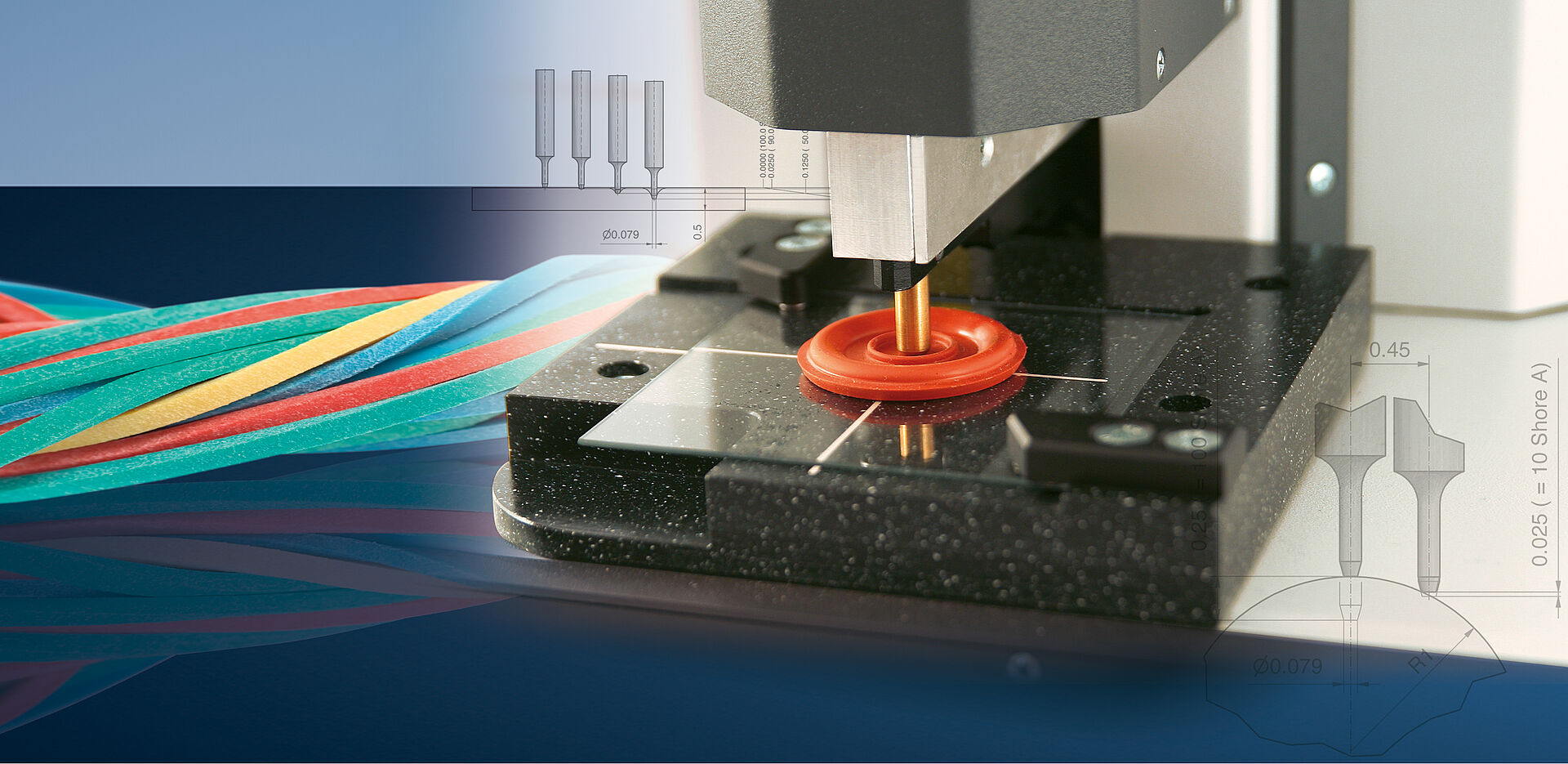

Il metodo di misurazione della durezza Shore si basa su procedure puramente fisiche. Per coprire il range di durezza più ampio possibile, sia la geometria dell’ago di prova, sia la progressione della forza sono preimpostate ai fini della misurazione. Se l’ago penetra solo a livello superficiale nell’elastomero duro, la forza di penetrazione viene aumentata. Questo permette di misurare con precisione sia i materiali morbidi, con una forza di penetrazione minore e un range di misurazione più grande, sia i materiali duri, con una profondità di penetrazione inferiore e, al contempo, una forza maggiore sulla punta dell’ago. Questa procedura standard consente di determinare la durezza a partire da uno spessore di prova minimo compreso fra 4 e 6 mm, con una superficie di appoggio di circa 18 mm di diametro. In questo processo si utilizzano in genere piastre di prova appositamente realizzate.

La nuova procedura di misurazione si basa sulla caratteristica di carico comparativo di corpi geometricamente miniaturizzati. Questo consente di misurare la durezza dei campioni di prova con una punta dieci volte più fine, che ha un diametro paragonabile a quello di un capello, con uno spessore a partire da 0,5 mm. Questo apre possibilità del tutto inedite. Ad esempio, è possibile variare una serie di parametri mirati utilizzati in fase di produzione, fra cui velocità di iniezione, temperatura di vulcanizzazione o grado di ricottura, per giungere a un risultato ottimale del prodotto, verificato nella prova di durezza. Il range di misurazione standard dei nuovi dispositivi va da 10 a 95 Shore A. Poiché l’ago di piccole dimensioni non viene pre-sollecitato, è possibile misurare anche materiali molto morbidi senza dover passare ad altri metodi di misurazione. A tale scopo, il range di misurazione può essere anche esteso a un range compreso fra –5 e 100 Shore A.

Misurazione precisa grazie all'azionamento miniaturizzato

Per determinare la particolare posizione di misurazione dei campioni ultra-miniaturizzati con il durometro Shore per range nanometrico, gli sviluppatori utilizzano uno speciale portacampioni con reticolo di posizionamento laser. In questo modo, il punto di penetrazione è definito per mezzo del reticolo, indipendentemente dalla geometria del pezzo. Le misurazioni in posizioni diverse, quali la cresta o il cavo d’onda, possono essere effettuate senza problemi sulla sommità della sporgenza o sulla superficie della base. Questa procedura può essere utilizzata con successo anche per i materiali compositi. Sono garantiti risultati di qualità a partire da una sezione di 1 mm². Una volta che il laser consente di puntare la posizione predefinita, il movimento di misurazione verticale dell’ago viene determinato con precisione mediante un servomotore miniaturizzato.

Nella scelta del motore, gli ingegneri applicativi FAULHABER hanno dovuto considerare diversi requisiti applicativi: un design piccolo per rispettare le misure compatte del dispositivo, il funzionamento in prevalenza autoalimentato del motore per ridurre il carico sull’elettronica del dispositivo e, naturalmente, un’elevata risoluzione in modalità di posizionamento. In questo caso in particolare, per dimensioni di misurazione di 35 mm di diametro e 83 mm di lunghezza si è rivelato ideale un servomotore CC con controllo di posizione integrato. Con una coppia di uscita di 50 mNm sull’albero e una potenza fino a 90 W, il sistema meccanico può essere posizionato senza alcun problema di sorta. Il controllo collegato fornisce un controllo di velocità, profili di velocità precisi e le modalità motore passo-passo e posizionamento. Quest’ultima risulta fondamentale. Con una risoluzione fino a 1/3.000 giri e la possibilità di tener conto della posizione dei contrassegni di riferimento e dei finecorsa, l’azionamento è in grado di rispettare le precise specifiche dell’elettronica dello strumento di misura.

Un’interfaccia RS232 consente la comunicazione con la logica esterna. Il controllo intelligente elabora tutti i dati relativi all’azionamento internamente, riducendo così il carico sull’apparecchiatura di misurazione elettronica. In più, nell’azionamento sono integrati l’autoprotezione da sovraccarichi e sovratensione nonché un’uscita di errore. Le funzioni desiderate, quali i programmi di esecuzione, le rampe di velocità ecc., possono essere salvate nel controllo di posizione.

La moderna tecnica di microazionamento è in grado di replicare in tutto e per tutto la versatilità dei propri omologhi tecnologici più grandi. Il sistema con sensori interni e la tecnologia di controllo elaborano i dati relativi all’azionamento all’interno dell’azionamento stesso. In questo modo, gli sviluppatori non devono più preoccuparsi della tecnica di azionamento vera e propria. In molti casi, ciò si traduce in una notevole riduzione sia dei costi generali di sviluppo, sia dei tempi di commercializzazione.

Prodotti