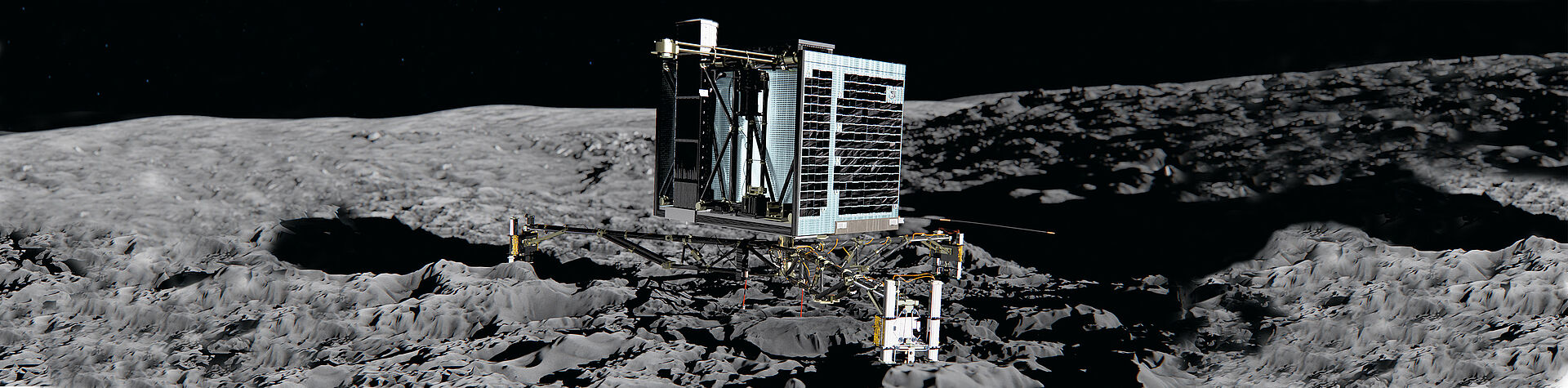

Come nel caso degli asteroidi, si ritiene che le comete (o stelle cadenti) siano i resti della genesi del nostro sistema solare. Si formano nelle regioni esterne più fredde. In prossimità del sole i nuclei delle comete, che di solito hanno un diametro di appena qualche chilometro, sono circondati da un velo nebuloso, la cosiddetta chioma, che gli conferisce il loro aspetto particolare. Le comete hanno sempre affascinato l'umanità. Nell'antichità, i greci e i romani pensavano che fossero presagi divini; nel medioevo erano considerate araldi del destino. Ora degli scienziati europei sono atterrati per la prima volta su una cometa per osservarla ed esaminarla da vicino e ottenere nuove informazioni sulle origini del nostro sistema solare. Ma un'impresa del genere esige molto dalla tecnologia impiegata. Di conseguenza, il lander a propulsione balistica ricorre a tutta una serie di azionamenti compatti che devono svolgere in modo affidabile le loro funzioni dopo i molti anni di volo spaziale. Ad esempio, devono funzionare durante l'atterraggio e mentre vengono svolte le analisi sulla superficie della cometa.

Philae è atterrato tre volte

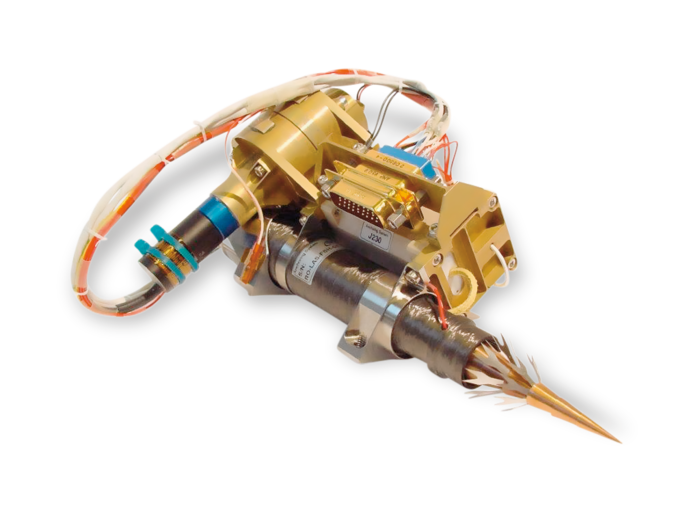

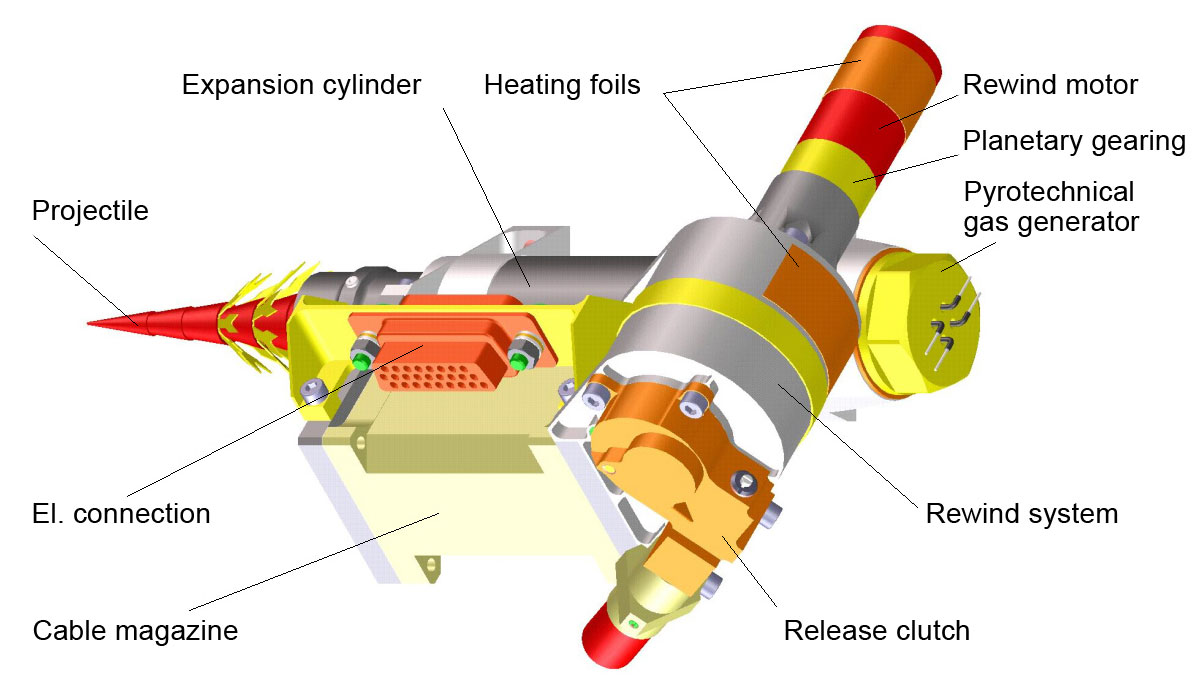

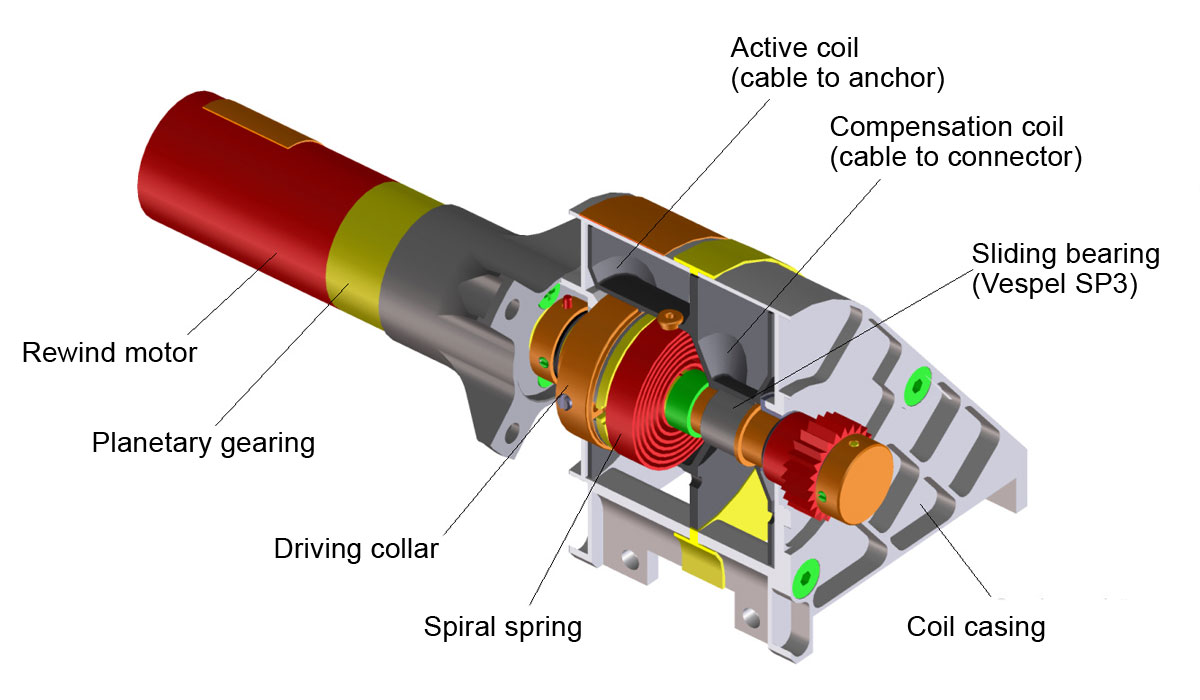

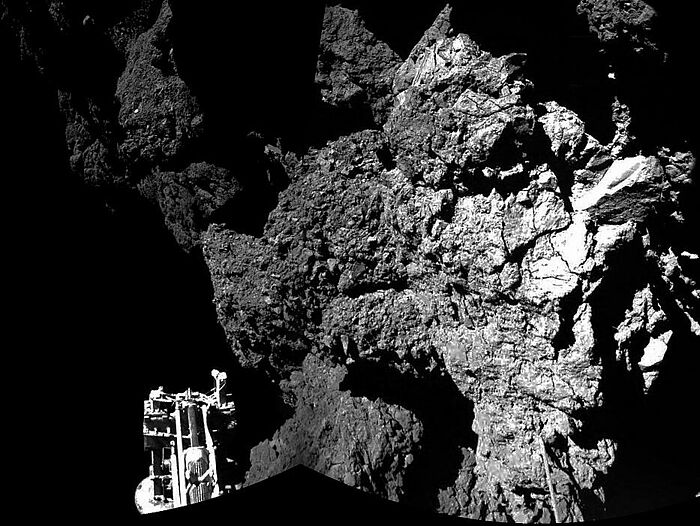

Data la gravità ridotta del corpo celeste, è difficile mantenersi saldamente sulla superficie e assicurare una posizione stabile anche durante l'intero periodo di funzionamento. Così, sotto l'egida del Centro aerospaziale tedesco (DLR - Deutsches Zentrum für Luft- und Raumfahrt), l'Istituto Max Planck di fisica extraterrestre (MPE) aveva sviluppato uno speciale sistema di ancoraggio per la sonda: subito dopo il contatto con il suolo a seguito dell'atterraggio, una carica di propellente doveva lanciare nella superficie della cometa due arpioni che vi si sarebbero conficcati. Delle punte uncinate avevano il compito di impedire un eventuale distacco successivo di questi ancoraggi. Al momento di essere lanciato, ciascun arpione avrebbe estratto un cavo da un caricatore. Poi questo cavo doveva avvolgersi e tendersi intorno ad un tamburo per mezzo di un servomotore brushless serie 1628 con un riduttore planetario 16/7, in modo da fissare la sonda alla superficie. Almeno questo era il piano. Ma purtroppo gli arpioni non furono lanciati, il meccanismo di riavvolgimento non venne usato e Philae finì per toccare il suolo tre volte senza ancorarsi alla cometa. Il laboratorio miniaturizzato fu tuttavia in grado di iniziare le sue analisi come previsto.

Carrello di atterraggio e analisi del campione

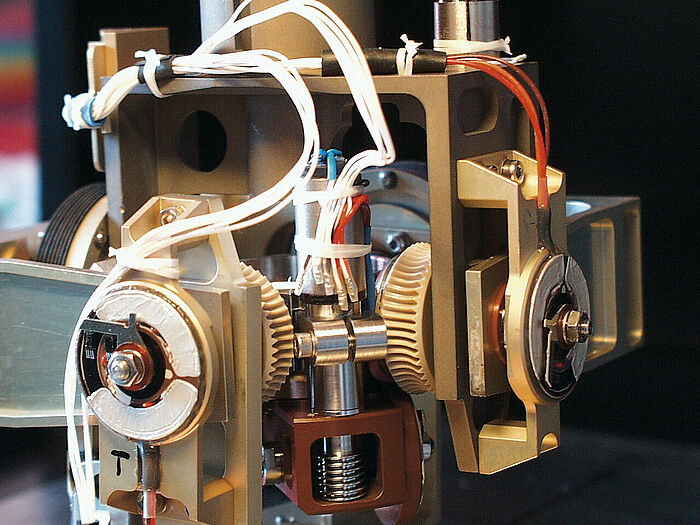

Durante la fase di atterraggio altri motori dovevano svolgere dei compiti importanti: per trasformare l'energia cinetica generata durante l'atterraggio (circa 50 J) in energia elettrica e infine in calore usando un azionamento a mandrino, un motore ad armatura a campana serie 3557 era stato collegato direttamente mediante una resistenza esterna e utilizzato come generatore. Ulteriori azionamenti della serie 1224 vennero usati nel carrello di atterraggio a tre piedi del lander, ad es. per far girare o ruotare la sezione superiore del lander per mezzo di un giunto cardanico e allineare così i pannelli solari in modo ottimale. Anche per prelevare i campioni erano necessari microazionamenti: il lander ha una trivella che convoglia i campioni di nucleo in un piccolo forno per pirolisi. Mediante una trasmissione a vite, piccoli motori serie 1016 con riduttore planetario 10/1 azionano una camma che posiziona un otturatore in ceramica sul rispettivo forno e allo stesso tempo chiude i contatti elettrici dell'elemento riscaldante del forno. Lungo tubi sottili situati nella chiusura del forno, il gas è convogliato verso strumenti scientifici a scopo di analisi. Durante la sua prima fase scientifica, che è durata in tutto 56 ore, il lander ha eseguito sulla superficie della cometa tutte le misurazioni scientifiche previste. Philae ha trasmesso correttamente questi dati al centro di controllo del lander e inoltre ha spostato la propria sezione superiore in modo da allinearla meglio rispetto al sole. L'agenzia europea ESA e il DLR considerano già la missione un successo completo. Per analizzare tutti i dati ricevuti ci vorrà del tempo.

Lo spazio e le sue esigenze

Lo spazio esige molto da questi azionamenti: ogni chilo di massa lanciata nello spazio costa energia, ossia combustibile, e di conseguenza denaro. Si cercano quindi soluzioni piccole e leggere. Ma allo stesso tempo queste soluzioni devono essere in grado di resistere alle enormi vibrazioni e forze di accelerazione che si generano durante il lancio, nonché a temperature costantemente bassissime e ai molti anni di condizioni di vuoto prevalenti nello spazio.

Dato che anche il fattore costi riveste un ruolo determinante nella scelta dei componenti per i progetti spaziali, gli sviluppatori hanno cercato di evitare, per quanto possibile, costosi sviluppi personalizzati. Pertanto, per prima cosa hanno preso in considerazione prodotti di serie che rispondessero il più possibile alle loro specifiche. Hanno trovato quello che cercavano nella vasta gamma di sistemi di azionamento di FAULHABER. Le soluzioni di azionamento standard proposte erano in grado di soddisfare tutti i requisiti meccanici. Le speciali condizioni specifiche dello spazio potevano poi essere soddisfatte apportando un numero comparativamente ridotto di modifiche con costi aggiuntivi trascurabili.

Messa a punto degli azionamenti standard

Ad esempio, un servomotore brushless CC con riduttori di precisione è servito da motore iniziale per azionare l'arpione di ancoraggio. Il motore e il riduttore hanno un diametro complessivo di appena 16 mm e una lunghezza complessiva di 61 mm. Il gioco ridotto della ruota dentata, inferiore a 1°, permette anch'esso un posizionamento più preciso. Si è riusciti ad integrare facilmente le soluzioni di azionamento grazie alle loro dimensioni compatte. Inoltre, il basso fabbisogno di energia le rendeva ideali per l'applicazione.

Come nel caso degli altri azionamenti utilizzati nel lander, anche la loro lubrificazione è stata adattata alle condizioni presenti nello spazio. In queste circostanze, grassi e oli sono inefficaci: si solidificano al freddo dello spazio o evaporano nel vuoto. I lubrificanti solidi offrono una soluzione promettente. Tuttavia la grafite è stata scartata perché lubrifica bene solo se tra gli strati di grafite è possibile la formazione di gas come il vapore acqueo o l'azoto. Questi gas non sono presenti nel vuoto; ciò che sulla Terra è un lubrificante solido, lì si comporta piuttosto come il gesso. Per la missione spaziale si è pertanto deciso di utilizzare del solfuro di molibdeno (MoS2), che presenta anch'esso una struttura simile a quella della grafite. Con questo composto la lubrificazione funziona nel vuoto e alle gelide temperature dello spazio, ma anche a temperature fino a diverse centinaia di gradi sopra lo zero. Questo lubrificante solido è stato dunque applicato alle superfici dei cuscinetti speciali da lubrificare e alle ruote dentate standard.

Anche l'alloggiamento del riduttore è stato adattato per l'impiego nello spazio. Le temperature molto basse, inferiori a -100 °C, e i differenti materiali possono portare a problemi di dilatazione termica nei componenti di precisione a causa dell'ostruzione. Per questo motivo, l'alloggiamento di serie del riduttore, realizzato in ottone nichelato, è stato sostituito con un alloggiamento in acciaio adeguato alle percentuali di dilatazione termica delle ruote dentate in acciaio. È stato possibile produrre l'alloggiamento in acciaio nello stabilimento per la produzione in serie di FAULHABER. Ciò ha contribuito a sua volta ad assicurare una perfetta intercambiabilità. Si è riusciti a mettere insieme facilmente gli elementi «rinforzati» adatti allo spazio grazie alla facilità di assemblaggio delle singole parti del riduttore. Gli azionamenti di serie modificati hanno dimostrato il proprio valore nello spazio così come avevano già fatto in molte altre applicazioni estreme, ad es. nei microscopi elettronici in condizioni di alto vuoto o nella produzione di chip.

Prodotti