Lo smaltimento dei rifiuti era e continua a essere di vitale importanza per la civiltà moderna. A provvedere a tale compito vi è anche il sistema fognario sotterraneo, responsabile di raccogliere le acque superficiali e di convogliarle verso l’impianto di depurazione. Un qualunque danno all’impianto può causare dilavamenti, allagamenti delle strade o la contaminazione di terreni e/o falde freatiche. È per questo che numerose normative in materia di acque reflue prevedono l’esecuzione di controlli periodici alla rete fognaria. Per ottenere un quadro della situazione nel sottosuolo e verificare l’eventuale presenza di danni, l’azienda IBAK, con sede a Kiel, ha sviluppato un sistema mobile di ispezione estremamente compatto, il cui fulcro è rappresentato da una telecamera miniaturizzata. La configurazione ideale è nata dalla collaborazione fra gli esperti dei sistemi fognari e gli specialisti dei microazionamenti FAULHABER. Più micromotori, dotati di trasmissione, muovono la telecamera in modo da consentire all’operatore di visionare l’impianto da qualunque angolazione.

Secondo le stime, l’effettiva lunghezza della rete fognaria tedesca è di quasi 1 milione di chilometri. Tutte queste condotte e canalizzazioni sotterranee sono soggette a vari tipi di sollecitazioni contemporaneamente: «aggressione interna» o corrosione, dovuta alla reazione chimica e biologica dell’acqua con le pareti dei tubi e agenti esterni, quali le vibrazioni generate dal traffico o il cedimento del terreno. A tutto ciò si aggiungono i danni provocati dalle radici degli alberi sui giunti di saldatura o le cricche nelle pareti, che possono causare anche lo scoppio delle tubazioni più resistenti. Nel tempo, si generano danni a cui è necessario porre rimedio nel più breve tempo possibile. Gli interventi di riparazione sui sistemi fognari possono essere molto costosi e lunghi e causare spesso gravi disagi al traffico in superficie. La precisione e la tempestività nell’individuare e localizzare l’entità dei danni fa sì che qualunque intervento di riparazione possa essere pianificato ed eseguito al meglio. Con l’ausilio dei sistemi di ispezione IBAK, la telecamera può viaggiare lungo l’intera rete fognaria, controllando e documentando le condizioni di tutti i tubi e componenti lungo il percorso.

Controllo in loco

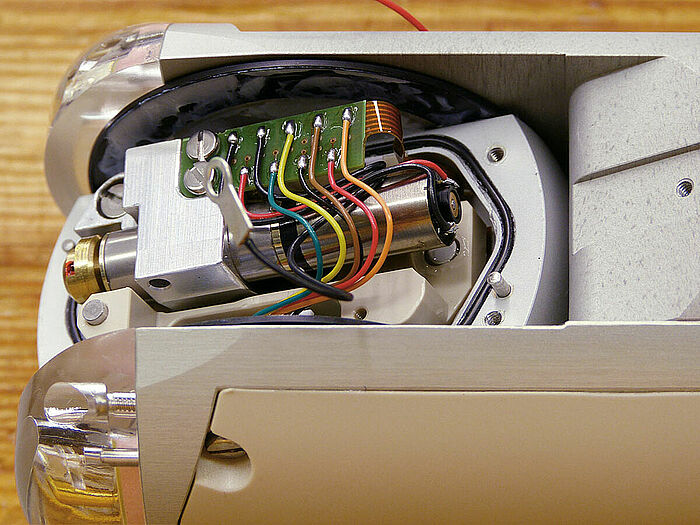

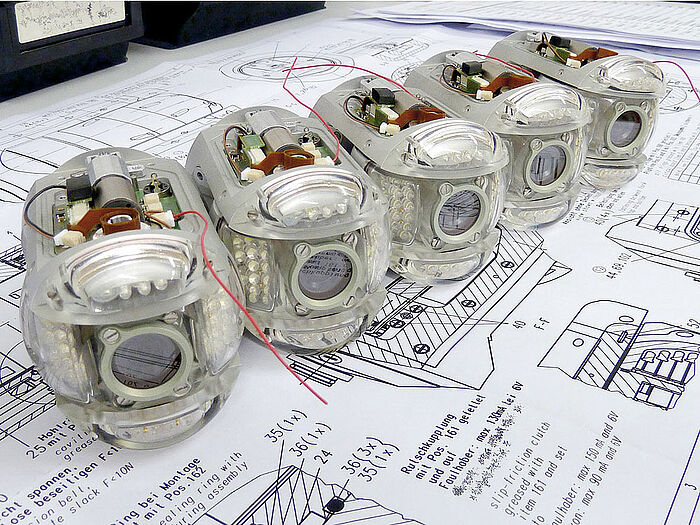

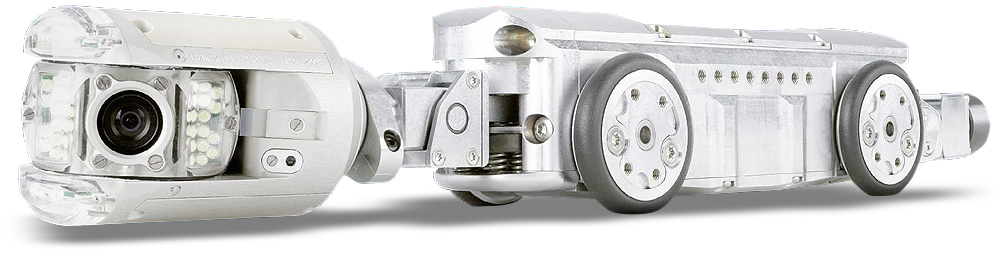

Oltre alla necessaria telecamera, un sistema di ispezione moderno include in genere anche un carrello, che consente alla telecamera di spostarsi lungo le tubazioni. Per illuminare il campo visivo, le telecamere IBAK sono dotate anche di un elemento di illuminazione integrato. Per l’uso in tubazioni di grande diametro, IBAK fornisce proiettori supplementari con un raggio d’azione maggiore. Oltre all’illuminazione, la dotazione «di bordo» comprende anche una vasta gamma di sensori elettronici, che consentono di definire il percorso da seguire all’interno delle tubazioni sotterranee, oltre a fornire misurazioni obiettive di qualunque oggetto incontrato lungo il tragitto. L’alimentazione e la trasmissione dati necessarie sono assicurate da un cavo per telecamera lungo fino a 500 metri, che collega il sistema di ispezione alla centralina di controllo in superficie. Oltre a questi componenti hardware, il sistema di ispezione necessita anche di numerosi software per la corretta ricezione e valutazione delle letture e delle immagini generate dai sensori. La caratteristica fondamentale di tutti i componenti utilizzati nelle condotte fognarie sotterranee è la compattezza nelle dimensioni e un elevato grado di affidabilità. Nel caso della telecamera ORION qui descritta, significa che la testina compatta con telecamera deve potersi muovere in tutte le direzioni. I «muscoli del collo» che consentono una tale mobilità a 360 gradi si devono ai tre motoriduttori della gamma prodotti FAULHABER. Un motore provvede all’attivazione del movimento di rotazione (costante) della testina, il secondo esegue la funzione di panoramica e il terzo interviene come motore di messa a fuoco per garantire la nitidezza delle immagini. Tutti e tre gli azionamenti funzionano in modo indipendente tra loro. Ad esempio, quando l’operatore muove la testina della telecamera in alto e in basso per eseguire una panoramica, l’intera testa è in grado di ruotare contemporaneamente anche intorno all’asse longitudinale per mostrare ciò che si trova nel tubo da ogni angolazione.

Piccolo, ma con una forma perfetta

L’azionamento rotativo fa muovere l'intera testina della telecamera. Dotato di un motore con diametro da 12 mm provvisto di alloggiamento in metallo, funziona a circa 0,5 W e 6 V. Dato che si tratta di un motore DC a commutazione in acciaio inox, la velocità è facilmente controllabile tramite modulazione della larghezza di impulso (PWM). Un riduttore planetario da 10 mm con rapporto di riduzione di 256:1 riduce la velocità complessiva e aumenta la coppia di uscita. I cuscinetti a sfera precaricati riducono al minimo il gioco e assicurano un movimento continuo, fondamentale per eseguire riprese senza tremolii. L’azionamento girevole e la messa a fuoco funzionano grazie a un motore largo 8 mm con un riduttore opportunamente compatto. Con una potenza di circa 0,2 W e un rapporto di riduzione di 1024:1, questi azionamenti consentono di eseguire regolazioni di rotazione, panoramica e messa a fuoco di grande precisione. Anche in questo caso, l’obiettivo è la massima accuratezza e versatilità. La telecamera, infatti, può eseguire riprese di qualità solo nella misura in cui lo consentono gli angoli impostati dall’operatore. Nonostante le dimensioni ridotte non superiori a 8-12 mm, questi motori vantano rispettivamente un’efficienza superiore al 70% e al 50%. I compatti motori DC a commutazione in acciaio inox, abbinati ad appositi riduttori, garantiscono un adattamento ottimale della velocità in uscita per ciascun uso specifico. L’operatore è perciò in grado di controllare agevolmente la coppia mediante la semplice modulazione della larghezza di impulso. I cuscinetti a sfera precaricati, leggeri e di lunga durata, presenti nel motore e nei riduttori consentono movimenti precisi e fluidi a partire da 0 giri al minuto. Questi piccoli concentrati di potenza, quindi, risultano ideali anche per i compiti più complessi in cui è richiesta la massima continuità di velocità o un posizionamento altamente preciso.

Prodotti