It's unlikely that even the most sophisticated robot can do a more effective job than a person if the task is to rescue disaster victims from a pile of rubble. A UGV (unmanned ground vehicle) such as the Recon Scout IR by ReconRobotics Inc. (Edina, Minnesota, U.S.) however can, in contrast to a human, explore a collapsed building without danger and send real-time pictures from there, which can be an important decision making tool for emergency workers when it comes to tactical responses. The Scout, looking to everyone like a small dumbbell, can climb up rough terrain or navigate along a specified path as instructed while transmitting a continuous flow of pictures, and all this while operating without a cable connection. Using sophisticated design, robust materials, and compact, high-torque servomotors from FAULHABER to build the device, ReconRobotics has positioned itself as a major player in the search and rescue robot market.

Tiny But Mighty

The UGV may be small but designing it was a tall order. The engineering team faced conflicting performance demands at every turn: The unit had to be powerful but small, high torque but with long lifetime on a single charge. This required compromises, optimisation of components and setting of priorities for the specifications. Nevertheless, the robot resulting from this process masters almost all of its tasks well.

The primary requirement was sufficient motive power – a search and rescue UGV isn’t much good if it can’t reach the target area. Travelling over rubble or uneven ground requires an appreciable amount of torque. Normally, an engineer would just choose a motor large enough to provide the power required, but the Scout’s compact form factor presented limitations. The second obvious approach, adding a high-reduction-ratio gearhead to convert motor speed to torque wasn’t an option – not only would it increase the drive's size beyond the available space, but it would only increase torque at the expense of reducing speed, which is unacceptable in a search and rescue robot.

This project required motors with a high power density and the diameter of a cigarette. The solution came from FAULHABER's sister company MICROMO in the U.S. with 8 and 10 mm direct current motors. “FAULHABER had the best available solution in the size range we were looking for”, says Patrick McKinney, chief operating officer of Recon Robotics. The motors were more typically used for medical applications, which brought the added benefit of a dependable solution. “They have to operate in an environment where lives depend on their function”, he adds. “We've had these motors running continuously in tests for well over 168 hours at a 50% load. They’re very impressive.” An additional planetary gearbox provides a 64:1 reduction ratio to raise the torque even further with a modest size increase.

The UGV cross beam contains an infrared-sensitive camera, IR illumination, as well as the motors and drive units, a controller, and the transceiver for the radio transmission of all data. The two wheels of the Recon Scout are driven independently of each other. For this purpose, a control system with a closed loop regulator circuit provides the control signals that have been processed accordingly. A gyroscope provides the z-axis feedback (yaw axis) and ensures that the wheels are driven evenly and the Scout can move along a straight line. To allow the UGV to be steered on the desired path, an accelerometer monitors x- and z-axis motion. A weighted stabilisation tail keeps the rotating position of the cross beam stable such that the camera lens remains correctly aligned for image acquisition.

Tough Stuff

Forget about driving to the region of interest; the Recon Scout IR is designed to be cast or dropped directly into the surveillance location. As a result, the ReconRobotics team had to design the unit to survive an impact on concrete from 30 vertical feet. They began with a chassis of aircraft-grade aluminium, which also helps dissipate heat. A titanium housing on the crossbar protects the contents. The wheels are made of proprietary polyethylene and also function as impact absorbers.

When the device lands after a throw, the wheels hit the ground with enough force to potentially strip the gears. To protect against this posibility, the team designed a patented mechanical clutch that disengages the gears on impact and reengages after the Scout has landed. With imager, illuminator, and wheels running constantly, the Scout has a percharge runtime of one hour, thanks to the high-efficiency operation of FAULHABER motors.

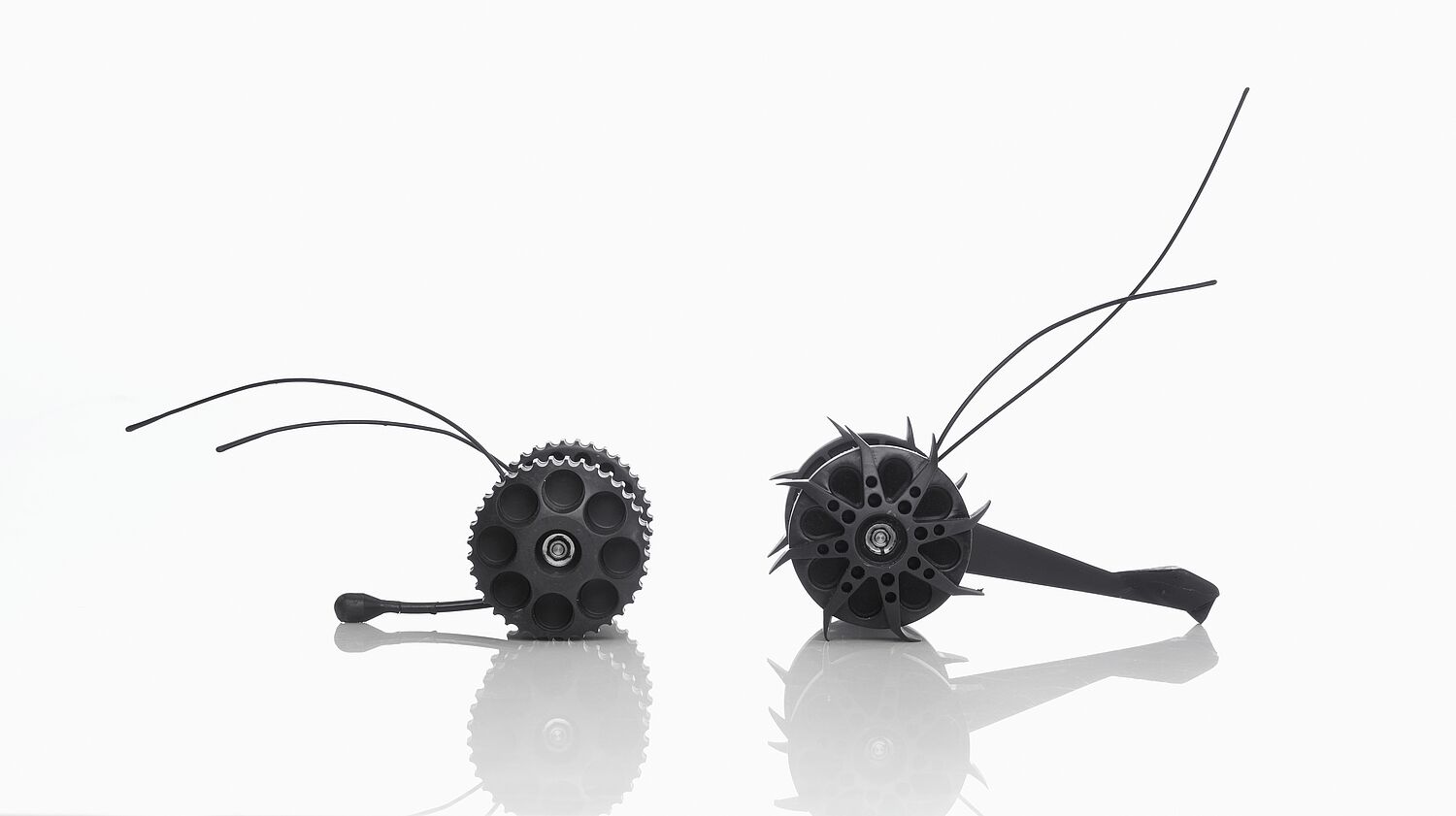

The original version of the Scout was a surveillance robot designed for military applications and for special assignments in a relatively clean urban environment. When the ReconRobotics group set out to develop the search and rescue version, they faced a new requirement of operation amid rubble, dirt, and heat. The customer specified that the 4-in-tall Scout be able to lift itself over 2-in-high objects unaided. Meeting that spec was a challenge for such a small machine, especially since the other requirements remained as strict as ever. The problem was solved by using a more powerful motor with 10 mm diameter, a slight widening of the wheels, and the fitting of terrifying inch-long spikes to improve the traction.

Products