In spectrophotometry, the amount and wavelength of light absorbed by a sample reveals the type and concentration of molecules present. Microvolume spectrophotometers such as the DS-11 let researchers obtain fast and accurate results, use the minimum amount of sample, and move more rapidly to answering the questions the research is trying to address.

For the optimal absorbance measurement, an optical path length (OPL) must be scaled for the size and characteristics of each sample. Unfortunately, the conversion factors typically used in these calculations assume a 10-mm OPL. As a result, the OPL must be adjusted for each sample and each measurement, then scaled to provide the true value. The more accurate and repeatable the OPL, the more accurate the results of the analysis. The key innovation of the DS-11 is DeNovix’ SmartPath Technology, which automatically optimizes the OPL to ensure trustworthy, usable results.

Design efficiency

From the outset, the DeNovix team designed the DS-11 for ease of use. The instrument incorporates an Android operating system for touchscreen operation and analysis without needing an additional PC. It consists of a 20 x 33-cm base with sample mounts available for microvolume and cuvette modes. In the microvolume design, an optical fiber carries the signal from a xenon lamp in the base of the instrument to the tip of the sample mount.

During a measurement, the user lowers a hinged measurement arm that puts a fiber-optic cable into contact with the sample. At the touch of the screen, the analysis algorithm begins running, continually fine tuning the mount position throughout a data-acquisition period.

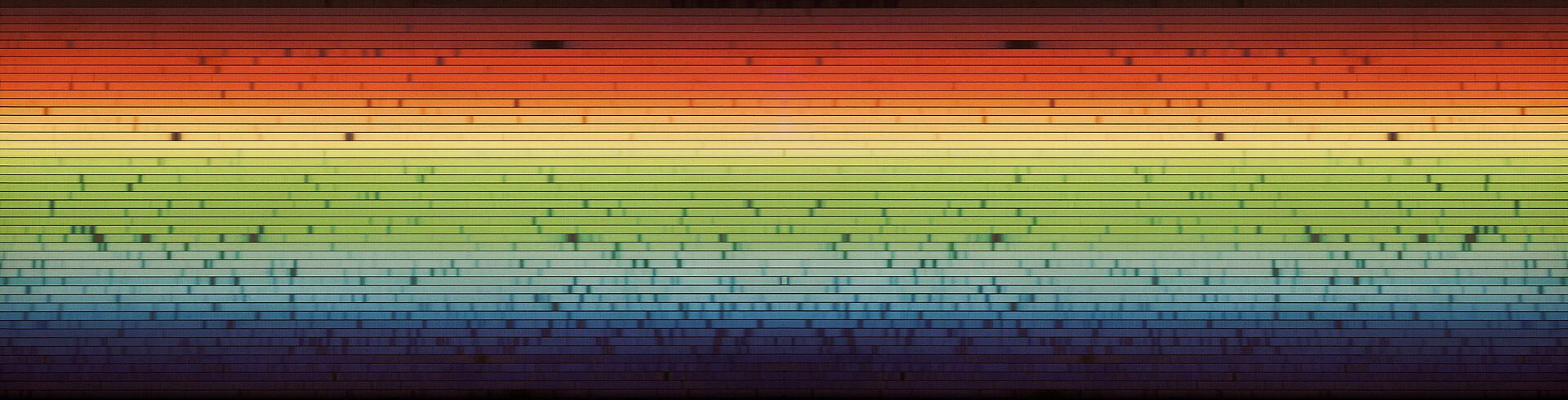

Electromagnetic energy (190 to 840 nm) passes through fiber and optical junctions, propagating to the spectrometer, where a 2,048-pixel linear CCD detector reads out counts for analysis.

SmartPath Technology uses an initial absorbance measurement to adjust the position of the sample mount to optimize the OPL. The system is based on sophisticated algorithms, but to work effectively, they require an accurate, closed-loop opto-mechanical positioning system capable of multiple iterations in a matter of seconds. As if this weren't challenging enough, the DeNovix team set themselves an ambitious product development timeline. They needed innovative engineering but also efficient design.

A first step was to simplify the design process by relaxing constraints. Instead of trying to optimize the OPL in three dimensions, they focused on positioning the sample mount along the z axis while letting it "float" in other dimensions. This removed components from the final device, reducing cost, integration time, and points of failure.

For z-axis positioning, the design drives a fine-threaded screw using a servo motor operating with closed-loop feedback. A planetary gearhead introduces a reduction ratio so that one rotation of the motor corresponds to a fractional rotation of the screw. A high-resolution magnetic encoder provides feedback to let the system iterate through the SmartPath algorithm and determine optimum OPL.

Picking a motor

The DeNovix team needed a motion solution that would do the job reliably and economically while letting them focus on their core value proposition, the spectrophotometer, and on getting their product to market as quickly as possible. The application called for intermittent short, quick motions with micron-level accuracy. After research and testing, they chose a coreless DC brushed motor module with an encoder and an all-plastic planetary gearhead, produced by FAULHABER.

The brushed motor significantly simplified the design-and-integration process. A standard brushless servo motor would have been more complicated. It would require eight connections: three power phases, three for the Hall-effect sensors, and two lines for powering the electronics. In contrast, a brushed motor only requires two connection points, making the drive scheme, assembly, and overall system more straightforward.

"Going with a brushed dc motor really uncomplicated our world," says Dave Ward, engineering manager at DeNovix. "That also meant that we had conventional braking capabilities. We wanted the best of both worlds. A passive system would be stable while it was taking measurements, and it let us develop an active braking algorithm. The combination gave us what the instrument needs: rapid, repeatable, precise motion.

” Many designers assume that a brushless motor gives the best performance, making it their first choice. It isn't always the ideal solution. It is true that a brushed motor will probably fail eventually due to wear between the brushes and commutator, but it's a question of time. Coreless dc motors with low inductance can last many thousands of hours, far beyond what most applications will ever need. The intermittent motions of the DS-11 gave the motion system a low duty cycle, letting a brushed dc motor solve the problem.

The choice of motor also helped the team achieve another design goal: speed of operation. Individual adjustments to the z-axis position of the sample mount take 0.25 to 0.5 sec, for a total data acquisition time of less than 4 sec. By selecting a coreless motor, the DeNovix team minimized inertia, enabling the motion axis to position rapidly and reliably without overshoot or ringing. "That’s where the motor comes into play," says Kevin Kelley, Business Director at DeNovix. "The system makes a lot of real-time decisions and the reaction speed of the motor lets it precisely control the path length, which is the most critical part of the apparatus."

Integrated modules

Once the team determined what they wanted, the next question was how to source it. They started with commercial off-the-shelf components and offloaded some of the headaches to their vendor by choosing a complete, pre-integrated gear motor from FAULHABER that arrives ready to install. "The biggest challenge was trying to get the product to market as quickly as possible, so the fact that several prototype motor assemblies were available for quick evaluation made this part of the project easy to deal with,” says Kelley. The motor company machined flats on the gearhead shaft in the prototype stage to aid with assembly. Now that the instrument has ramped up to production volume, the flats are machined in at the factory.

Taking delivery on a motion module lets DeNovix focus on the optics and leave the motion design to us. It also streamlines manufacturing, as well as eliminating the risk of damaging motion components during integration. "We didn’t want to build it piece-meal," says Ward, "so the integrated package was important."

With the aid of SmartPath Technology, powered by precision motion, the DS-11 can measure samples with OPLs as low as 0.03 mm. This correlates to 500 absorbance units at the standard 10-mm equivalent OPL, which represents a BSA protein concentration of 750 mg/mL or dsDNA concentration of 25000 ng/µL. Powered by the reliable motion system, the instrument demonstrates a repeatability of better than 1%.

The system survived rigorous lifetime testing. To date, DeNovix has had no reported motor failures in the field, a fact they credit in part to the performance of the motion control module.

Products