How did your robot platform come about?

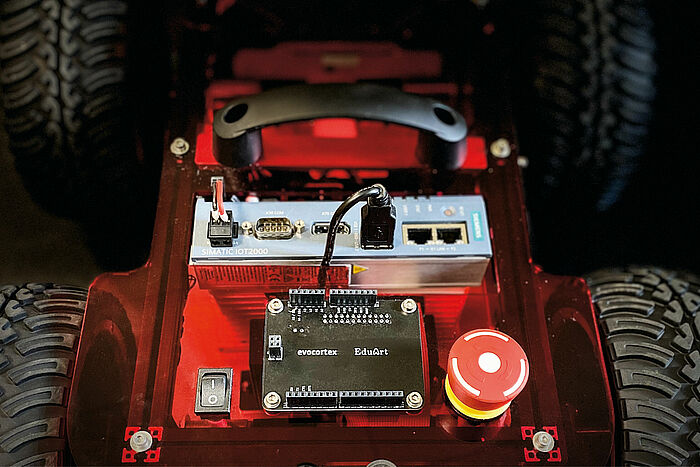

It started as a result of an inquiry from a company to Prof. Stefan May. The company needed a platform to educate and train their employees on mobile robotics. Subsequently, we developed “EduArt” together. In addition to the robot platform, EduArt Robotik GmbH provides a range of teaching and service offerings for testing and optimization.

What makes your robot platform unique?

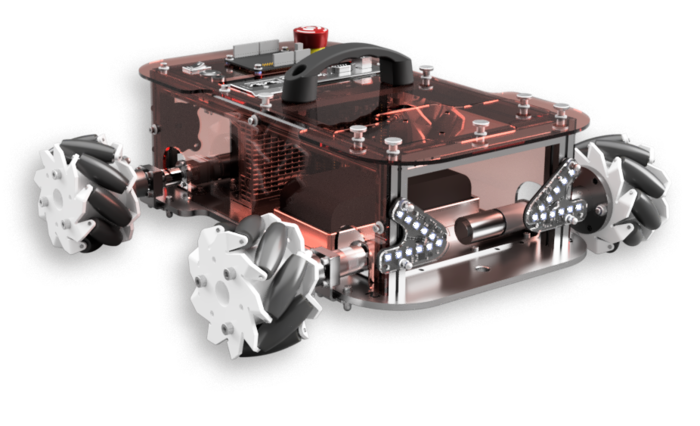

The robot is about 40 x 40 x 15 cm in size and weighs almost 8 kg. The platform offers simple rubber tires as well as mecanum wheels. These allow the robot to turn on the spot, drive sideways or diagonally. This enables exact positioning and navigation in very tight spaces. The rubber tires are mainly used for testing in outdoor areas or in rescue robotics, but only in pretend scenarios. The use of high-quality FAULHABER motors is ideal for both applications.

Furthermore, the platform has open interfaces, an integrated sensor concept with integrated distance and inertial measuring devices, and an integrated battery management system (BMS). This basic equipment can be expanded at the customer's request, either by us or the customer himself. This allows the customer to, e.g., select the gear ratio of the drive, whether 72:1 or 89:1, depending on the speed or torque required. This enables the customer to cost-efficiently test his new concepts. But we are also helping with the implementation of application solutions.

How relevant is the use of EduArt in the industry?

AGV and AMR are becoming more and more important for automation, but unfortunately companies are largely uninformed. The robot platform, for example, makes it possible to quickly and easily test a new sensor system. And because the platform can virtually be expanded as needed, it can bring the relevant knowledge into production.

The trends for AGVs and AMRs are towards more autonomy. They are becoming a production component and work with production modules instead of conveyor belts. So AGVs and AMRs work together out of necessity. Are they able to understand each other?

AGVs and AMRs have the VDA5050 standard interface and can thus also communicate with the control center. Customers can easily test new software using a platform like EduArt, and the results can be transferred 1:1 to large AGVs and AMRs. Applications can thus be evaluated without much simulation, because the software essentially remains the same, whether with EduArt or with a large system. A digital twin helps with the planning and expansion, this is available with the platform on request.

EduArt's drive systems also have to meet the future requirements of AGV and AMR concepts. Which drive systems do you use for the platform and why?

For our training and PoC platform we are using DC-micromotors with precious metal commutation from FAULHABER. They are capable of generating high torques despite their small size and are particularly power efficient. They are also easy to control and are suitable for high-precision control loops.

For larger platforms, we use large DC-motors from the same manufacturer to enable a quick proof of concept, e.g., easy controllability with own electronics. Where necessary and depending on the application, we have replaced these with BLDC motors, because they are maintenance-free and durable.

For a long time, production has been characterized by decreasing lot sizes and a greater number of variants. What effects does this have on logistics and on the functionality of AGVs and AMRs?

In this context robots are needed for smaller loads, i.e., smaller robots with smaller but more powerful drives, like the high-quality drives from FAULHABER. These autonomous industrial trucks have fewer electronics and smaller batteries, which means lower weight and decreased energy consumption. If the loads get higher again at any time, it is easy to scale up and work as a unit, as the robots are able to work together collision-free thanks to high-precision drives.

More functionality requires more complexity in AGVs and AMRs: What is feasible and what makes sense in this regard?

When it comes to AGVs and AMRs, only the software is complex. What is important is the planning, so that AGVs can work together seamlessly. To ensure that it not only recognizes pallets, but also sees whether these are full or empty or perhaps tilted, the AGV must be as intelligent as possible. This is where AI (Artificial Intelligence) comes into play. The complexity will increase due to the use of AI. Our small robot is suitable for testing this efficiently.

Another trend is towards larger automated fleets. For that you need fleet management.

For this the robots have to interact with each other, “think” themselves, exchange information via standard interfaces and, if necessary, cooperate. Whether these are small or large AGVs/AMRs only has a small impact on the software. Short of a few different lines in the program, they are essentially the same. The software only needs little information about the AMR. It only has to calculate where the robot is located on the hall plan. The navigation, which is one of the few components that knows the dimensions of the robot, then searches for the appropriate path. But testing remains an important factor, because mobile robotics is still in its infancy and has few standards.

In order to reach the required speed, the motor controller calculates the number of wheel revolutions required. Adjusting this requires three lines in the program code or a configuration file. FAULHABER supplies motors with high-precision gearheads and encoders for precise positioning for this, which together provide optimum performance and safety.

Intralogistics 4.0/Industry 4.0 require networked AGVs and AMRs: Does the networking take place via the cloud or is it better via the edge? And what about security and protection from hackers?

Depending on the manufacturer, the systems can be made "unhackable" to a certain extent by separating the hardware from the Internet. Robots have safety scanners with distance sensors so they don't hit the wall. This means that even if hacked, no dangerous movements can be triggered on the robot. And the process data is as secure in the network as the company network itself.

One of the goals of the Industry 4.0 are self-organizing, heterogeneous, multimodal systems. These require the exchange of data between AGVs and AMRs, and AI also requires data. What are the requirements for FAULHABER components, as they also have to collect and forward data?

This takes place via 5G or via the company's internal WLAN. The systems do not need the data in real time because the data from the planning phase is already available. For example, the routes and speeds are available in the system in the route planning and do not change continuously. If the robot moves from one point to the next, a sign of life every few seconds is all it takes. This means less data traffic and the networks are not overloaded. The available data are compiled and evaluated on the AMR. Encoders record what is happening and ensure safe control with the controllers.

How safe are AGVs and AMRs?

Very safe. If one of four motors fails, the motor controller recognizes it and stops the drive. If a person enters the driving area, this is recognized by the laser scanner and the system brakes. These two safety levels are sufficient.

Where is research still needed for the development of future AGVs and AMRs, and how does that impact the requirements on your test platform? At the same time, the demands on drives are also increasing. What about the drive of the future?

Robots still have to be better networked with each other. For example, if four small robots instead of one large robot are working on a transport task together, you need small motors that work very precisely. Otherwise, the robot swarm will stumble or lose its synchronization. In order to improve reliability, encoders must be absolutely immune to interference so that the robot is not influenced by external interferences. For this reason, FAULHABER sometimes uses two encoders on each motor.

When you combine the different motor variants from FAULHABER with gearheads, encoders, controllers etc., you theoretically get 25 million combinations. A considerable percentage of which has already be realized by FAULHABER. This enables every company to find the optimal drives for current and future uses.

Products