Prosthetics with disadvantages

If one follows the sports competitions for disabled persons, such as the Paralympics, it is amazing to see the level that prosthetics have attained these days. For example, in the summer of 2014 the erman long jumper Markus Rehm was not allowed to travel to the European Athletics Championships because the German association was afraid that, with his carbon leg prosthesis, he would have an advantage in jumping vis-à-vis non-disabled sportsmen. And yet the sophisticated prosthetics made of carbon and other materials have a decisive disadvantage: the bearer cannot truly use them just the same as he would the missing part of the body. The hand prostheses available on the market detect muscular movements in the residual limb somewhat, and enable the bearer to open and close the hand as well as to grasp objects. But without any sensory feedback to the nervous system, the bearer cannot feel what he is attempting to grasp and must therefore keep an eye on his prosthesis so that he does not crush the objects.

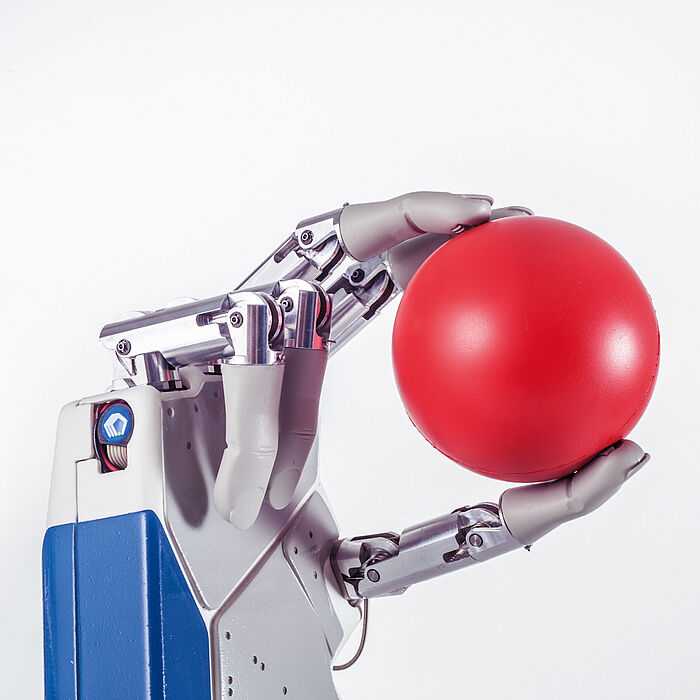

Comparable with a natural hand

A major step in progress was achieved with the LifeHand 2 project. The artificial hand makes fascinating things possible for the bearer: he can grasp objects with suitable pressure and, via contact sensors, feel which attributes they have. The bearer can even feel which exact fingers have contact with the object. The size and the weight of the prosthesis are thereby comparable with those of a natural hand. LifeHand 2 is equipped with sensors which register tactile sensations by measuring the tension in the artificial tendons and controlling the finger movements. These data are then transformed into electrical signals which are then transmitted to the nerves. This is made possible through electrodes to the nerve fibres, which convey signals to the bearer's brain. A computer translates the signals from the sensors into pulses which the nerves can interpret. They are further transmitted via electrodes to the median nerve (nervus medianus) and the ulnar nerve (nervus ulnaris).

An international research team developed the bionic hand prosthesis at the École Polytechnique Fédérale de Lausanne (EPFL). Six research institutes in Italy, Switzerland and Germany were involved. Professor Silvestro Micera and his team from the Scuola Superiore Sant’Anna (SSSA) in Italy developed the sensory feedback system, thanks to which a patient can feel something again when touching and moving objects.

In February of 2013, a prototype of the LifeHand 2 was tested in the Gemelli hospital in Rome within the scope of a clinical study supervised by Paolo Maria Rossini. The Dane Dennis Aabo Sørensen volunteered to be the first test person for the LifeHand 2. Nine years ago he had lost his left hand in an accident. Four microscopic interfaces were grafted onto the main nerves of his left arm. After the electrodes had been surgically implanted and the wounds had healed, the prosthesis could be connected. When Sørensen touched objects, the sensors of the prosthesis generated signals which were processed by a computer and relayed through a stimulator to the electrodes implanted in the nerves and, ultimately, to his brain. This all took place in less than 100 milliseconds. With such minimum time intervals, human beings don't sense any delay in transmission. Sørensen was able to recognise the shape, consistency and position of objects in real-time and use this information in order to grasp the objects with the proper grip and appropriate application of force by controlling his fingers.

The research team was surprised just how quickly Sørensen was able to control the prosthesis. For the tests, the researchers blindfolded Sørensen and then asked him to pick up objects with the LifeHand. He succeeded in not only controlling the strength of his grip, but also in describing the shape and texture of the objects – although he could not see them.

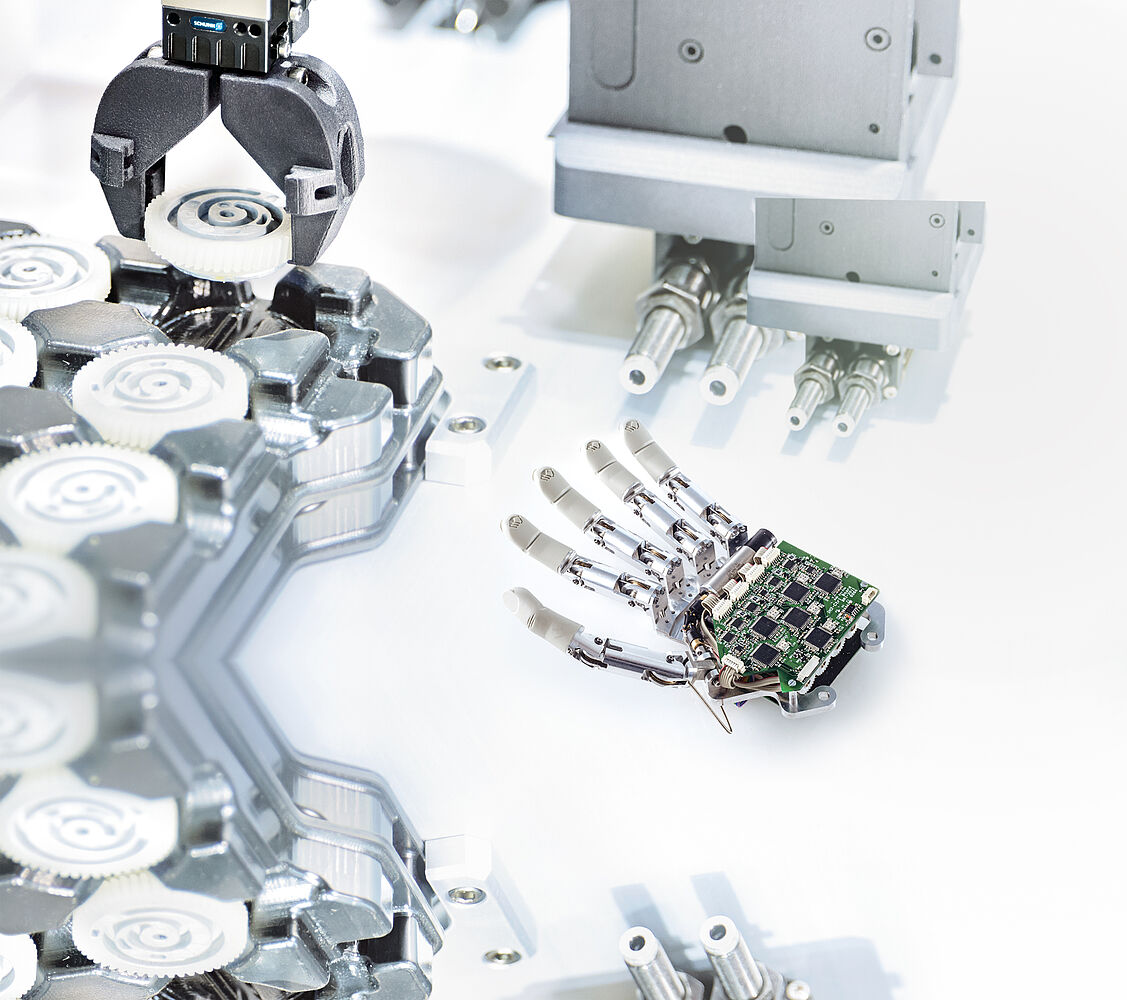

Sophisticated motors from FAULHABER

The finely-detailed workmanship, which the Life-Hand thumb and fingers put into effect, are implemented with DC micromotors from FAULHABER. With a motor diameter of 13 millimetres and a motor length of 31 millimetres, the motors are lightweight and compact. A unique aspect of the FAULHABER DC motors is their rotor, which is not wound around an iron core, but instead consists of a copper coil manufactured with a self-supporting, skew-wound design. The FAULHABER rotor has also proven itself convincingly in the Lifehand project with its extremely low inertia torque and cogging-free running properties.

Products