Their vision is clearly formulated: Magazino aims to create the world's first selfthinking and selfacting warehouse – and is well on the way to doing so. The new logistics robot is called TORU and is currently proving itself in practical tests with major shipping service providers. These use the intelligent, selfdriving system above all for retrieving shoeboxes during order picking. Conceptionally, TORU is a socalled perception-controlled robot. Through the use of cameras, image processing, sensors and artificial intelligence, it is able to perceive and correctly interpret its environment and use this as a basis to make decisions.

Robot creates its own picture of its surroundings

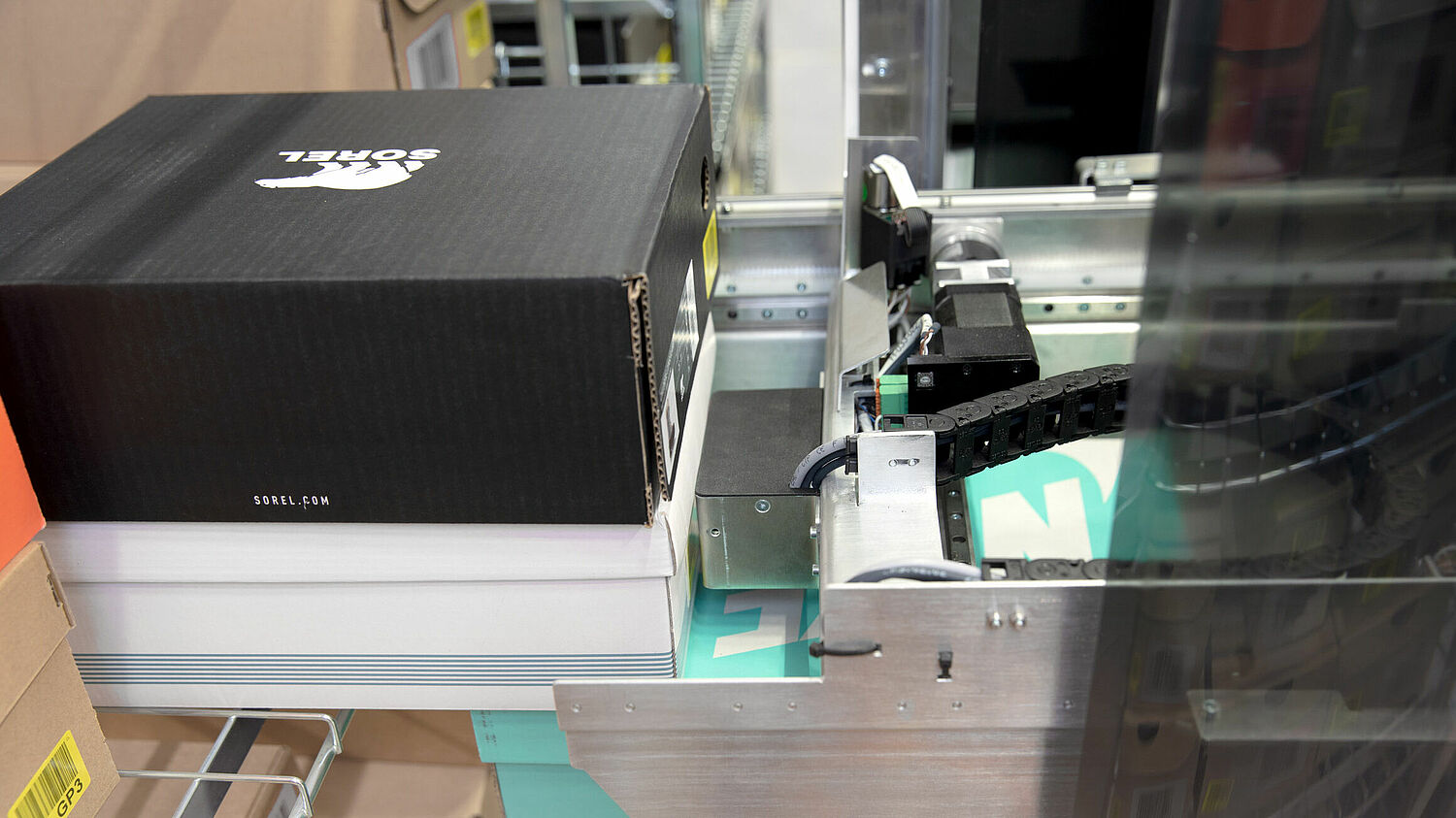

Make decisions? When TORU receives an order to pick a certain pair of shoes, it is first given the warehouse address plus a bar code. Thus, the robot knows where the target bin must be located and navigates right up to the address. The lifting column at the front of the vehicle then rotates 90 degrees towards the shelf, a gripper moves to the specified bin and now TORU begins to make decisions on its own. Using threedimensional camera images, the robot first produces a picture of the current situation. "Is there even a shoebox on the shelf? Is the right bar code present? Am I able to grip the carton: perhaps it was moved a couple centimetres to the side and would jam when pulling out?" With these questions, Magazino spokesperson Florin Wahl describes the primary tasks of the visual analysis. It is the answers that make the system from Munich so unique. If a picking order is linked to a carton that was placed on the shelf somewhat askew by an employee, the robot attempts to adapt its gripper process to the circumstances. If TORU ascertains that gripping is still not possible, the job is returned to the system – and a warehouse employee would need to perform the order picking by hand.

If no problems are detected, it is above all drives from FAULHABER that are responsible for handling the shoeboxes. Here, Motion Controllers, brushless DC servomotors of the BX4 series and planetary gearheads form a drive system that extends and retracts a metal tongue. The task in this case is to close the gap between the vehicle and the bottom of the shelf. The path is thereby levelled, allowing the cartons to be pulled out on the flat surface with negative pressure.

High overload behaviour

For the positioning of the suction gripper along a toothed rack, Magazino uses type BX4 drives from FAULHABER. With a power of 62 watts, the brushless DCservomotors deliver rated torques of up to 72 mNm in continuous operation. Interesting for Magazino are the peak torques of up to 96 mNm. The overload capability is decisive for overcoming the breakaway torques when handling the shoeboxes. "We need motors with high power density," explains Raphael Vering from engineering development at Magazino. Because the peak torques are only called for in a very narrow time window, there is no risk of the motors becoming too hot.

Smaller drives

The powerful overload behaviour of the motors – with their diameter of just 32 millimetres – offers the Munich logistics pioneers a number of advantages. The design provides the basis for being able to use smaller motors through the reliable handling of the breakaway torques. The result is that smaller drives are inherently lighter. "The mass of the gripper needs to be as low as possible because it has to be moved along the vertical axis with TORU," explains Raphael Vering. The heavier the gripper unit, the greater the required motor power of the vertical axis. Then there is the question of the centre of mass when TORU needs to grip a shoebox located on the top level of a two-metre rack.

Without question: the centre of mass can easily be shifted downwards by using a thicker base plate. This, however, makes the travel unit heavier. As a result, a stronger drive motor is needed. This, in turn, requires more power from the battery, thereby reducing the range. A lightweight design is also necessary because TORU is to be used not only on solid concrete on the ground floor, but also on more delicate ceiling constructions of intermediate levels. "Here in particular, the surface loads are very limited. We want to make TORU as versatile as possible, however," notes Florin Wahl. Larger motors would also inhibit handling – especially when cartons are stored just a few centimetres above the floor and it is necessary that the drives simply not be in the way. With the FAULHABER solution, Magazino is able to move down very low and up again. "This is extremely important when we consider the capacity of a warehouse with respect to the floor area. Every additional shelf space is worth gold," summarises Florin Wahl.

The idea behind TORU lies in the implementation of a sophisticated system of automation, robotics, vision and autonomous driving. When evaluating the drives, Magazino was therefore in search of solutions with optimum power density. These in, turn, must be capable of being elegantly integrated in the existing automation concept. "Support of CANopen communication was decisive for us," reflects Raphael Vering. Because the Munich firm was also able to use a perfectly fitting, complete Motion Control system from FAULHABER, the development department had more freedom for further optimisations of the new logistics solution. "We don't need to invest any time in our own controllers or in the integration of encoders," emphasises Vering. With the DC-servomotors, the FAULHABER Motion Controllers of the V2.5 generation form highly dynamic positioning systems. For feedback control, Magazino uses analog Hall sensors, thereby eliminating the need for a separate encoder for feedback. The integrated current control of the Motion Controllers limits the torque and thereby protects the electronics and motor from overload. Magazino, in turn, uses this function to detect faults in material flow – such as if a shoebox has jammed in a shelf compartment, causing the removal unit to stop.

The bottom line

With TORU, Magazino has succeeded in developing a material handling solution that can simply and reliably improve efficiency in logistics. The current employment situation in Germany makes the potential offered by this invention clear. Labour is in short supply – especially at night and on weekends. But this is when most online shopping takes place. The use of autonomously and intelligently acting logistics robots would be a way to at least prepare order picking at the start of the week. For this purpose, TORU is equipped with a travelling shelf into which the removed boxes are inserted. Centring units with FAULHABER drives help to position the boxes in a space-saving manner.

Products