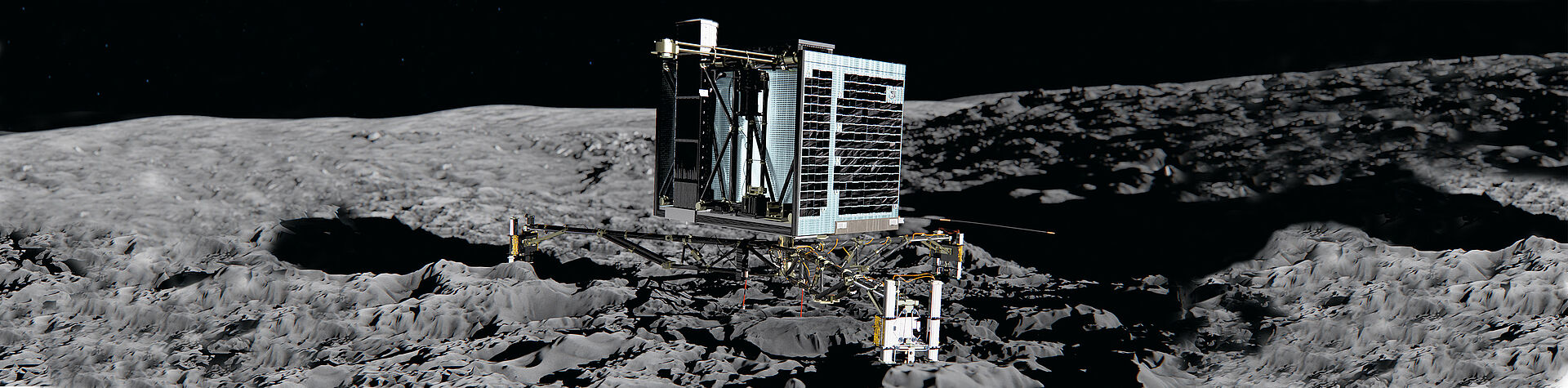

As is the case with asteroids, comets (or shooting stars) are considered to be the remnants of the genesis of our solar system. They are formed in the cold outer reaches. In proximity to the sun, the comet nuclei – which are usually just a few kilometres in diameter – are surrounded by a nebulous shroud, the so-called coma; this is what gives them their typical appearance. Comets have always fascinated mankind. In the antiquity, ancient Greeks and Romans thought them to be divine omens; in the Middle Ages, they were considered to be harbingers of fate. Now, European scientists have for the first time landed on a comet to observe and examine it close up and so to gain new insights into the origins of our solar system. An endeavour such as this places high demands on the technology that is employed, though. Consequently, the ballistically-propelled lander makes use of an entire series of compact drives, which must reliably fulfil their functions after the spaceflight of many years. For example, they must operate during the landing and while analyses are being performed on the surface of the comet.

Philae touched down three times

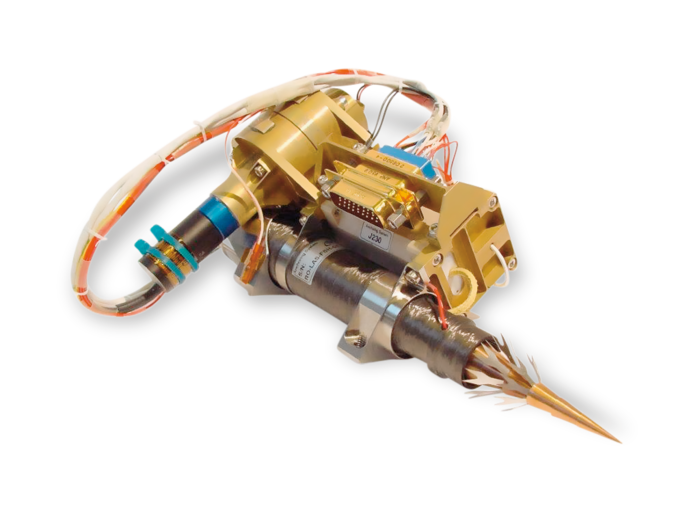

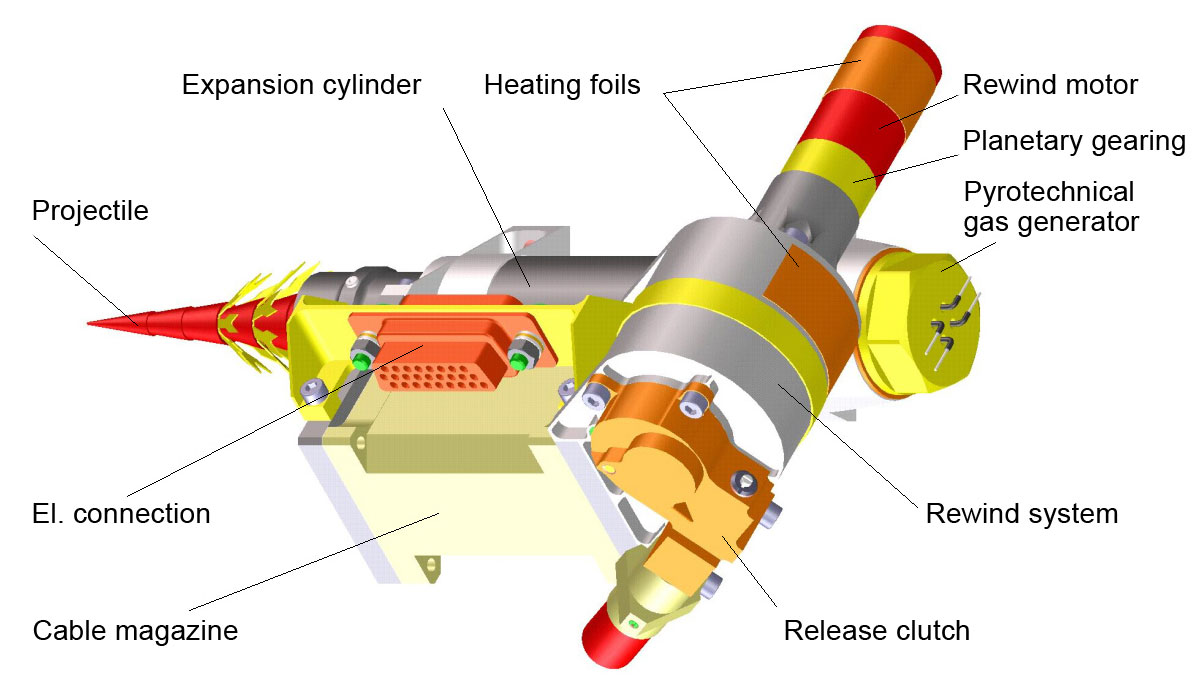

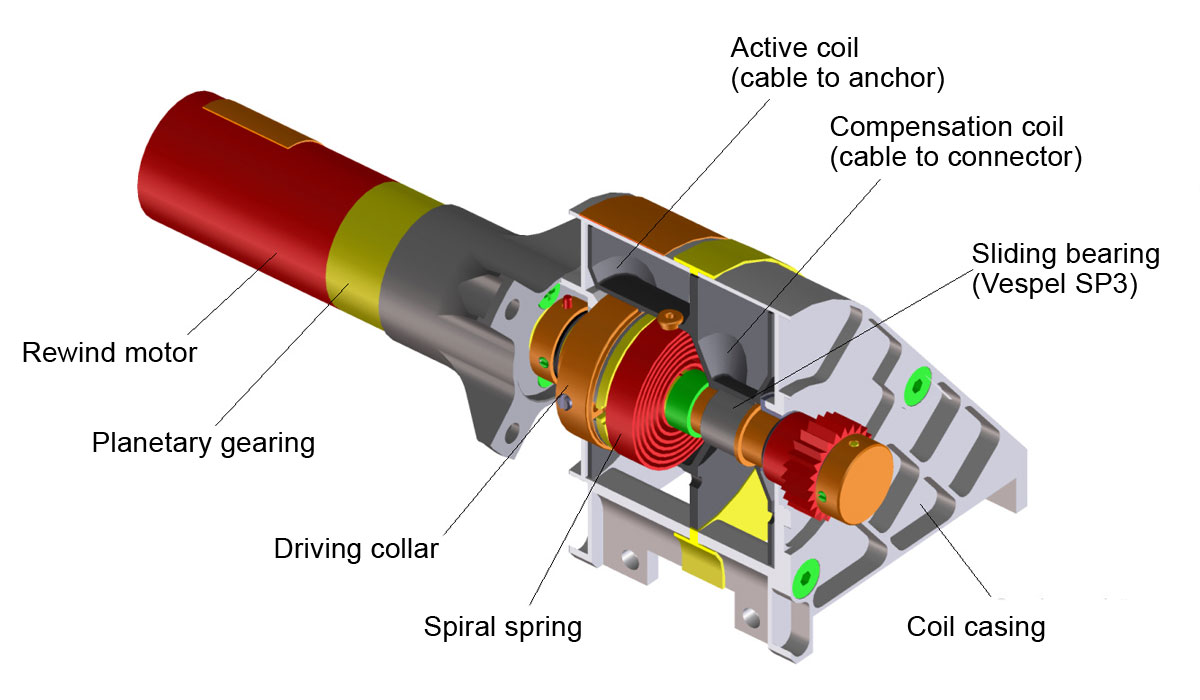

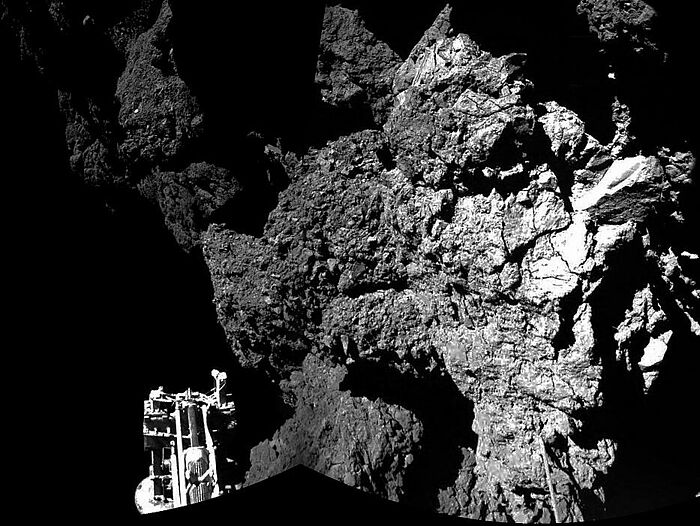

Because of the low gravity of the celestial body, it is difficult find firm footing on the surface and to also ensure a secure stance during the entire operating period. Thus, under the auspices of the DLR (Deutsches Zentrums für Luft- und Raumfahrt; German Aerospace Center), the Max-Planck-Institut for Extraterrestrial Physics (MPE) developed a special anchor system for the probe: immediately after ground contact upon landing, two harpoons were to be shot by a propellant charge into the surface of the comet and lodge into it. Barbs were provided to prevent these anchor fittings from coming loose again. As each harpoon shot out, it would have pulled a cable out from a magazine. This cable would then be wound up on a drum until taut by means of a 1628 series brushless servomotor with a 16/7 planetary gearhead in order to secure the probe to the surface. At least that was the plan – unfortunately the harpoons were not fired, the rewinding mechanism was not used and Philae ended up touching down three times without anchoring to the comet. Nevertheless, the miniature laboratory was still able to begin its analyses as planned.

Landing gear and sample analysis

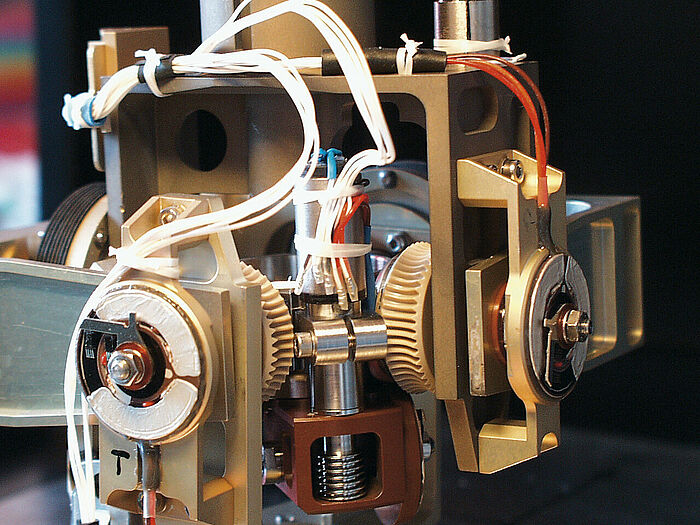

During the landing phase, other motors had further important tasks to perform: In order to transform the kinetic energy generated during the landing (approx. 50 J) into electrical energy and finally into heat using a spindle drive, a 3557 series bell-type armature motor was connected directly through an external resistor and operated as a generator. Additional drives from the 1224 series are used in the three-legged landing gear of the lander, e.g. in order to swivel or rotate the upper part of the lander by means of a cardan joint so that the solar panels can be optimally aligned. And, microdrives were also needed for taking the samples: The lander has a drill that feeds core samples into a small oven for pyrolysis. Small 1016 series motors with 10/1 planetary gearhead drive a cam via a worm drive, which feeds to a ceramic breech piece on the respective oven and simultaneously closes the electrical contacts for the oven heating element. The gas is routed through thin tubes in the oven latch to the scientific instruments for analysis. During its first scientific phase which lasted a total of 56 hours, the lander performed all of the planned scientific measurements on the comet surface. Philae successfully transmitted this data to the Lander Control Center and, furthermore, has moved its upper part so that it is better aligned with the sun. ESA and DLR already regard the mission as a complete success. Evaluation of all of the received data will take some time.

Outer space and its demands

The demands that outer space place on these drives are high: every kilo of mass that is shot into space costs energy, i.e. fuel – hence money too. Therefore, small, light solutions are sought. At the same time, however, they must also be able to withstand the enormous vibration and acceleration forces during take-off, as well as the constant very-low temperatures and the many years of vacuum conditions prevailing in outer space.

Because the cost factor also plays a major role in all considerations when selecting components for space projects, the developers wanted to do without costly custom developments if at all possible. Accordingly, they first looked for series products which complied with as many of their specifications as possible. They found what they were looking for in the comprehensive drive systems product range from FAULHABER. Standard drive solutions they offered fulfilled all mechanical requirements. The special conditions in space could then be met by making comparably few modifications that entailed negligible additional costs.

Tuning for standard drives

For example, a brushless DC servomotor with precision gearheads served as the initial motor for driving the anchor harpoon. Motor and gearhead together measure only 16 mm in diameter and 61 mm in length. Low gear play of less than 1° also allows for much more precise positioning. Thanks to their compact dimensions, the drive solutions could be easily integrated. Their low power requirements were also ideally suited to the application.

As was the case with the other drives used in the lander, their lubrication was also adapted to the conditions in space. Greases or oils are ineffective under these circumstances; they either solidify in the cold of outer space or vaporise in the vacuum. Solid lubricants offer a promising remedy to this. Graphite was rejected, though, because it only lubricates well if gases such as water vapour or nitrogen can be built up between the layers of graphite. These gases are lacking in a vacuum; that which is a solid lubricant on earth then acts more like chalk. Which is why it was decided to use molybdenum disulphide (MoS2) for the space mission, which also has a graphite-like layer structure. With it, the lubrication also functions in a vacuum and in the frigid temperatures of outer space, but also at temperatures of up to several hundred degrees Celsius. This solid lubricant was therefore applied to the surfaces of the special bearings to be lubricated and the standard gear wheels.

The gearhead housing had to also be made suitable for deployment in outer space. Deep temperatures of less than -100 °C and different materials can lead to thermal expansion problems with precision parts due to blockage. For this reason, the standard nickel-plated brass housing of the gearhead was replaced by a steel housing, which is matched to the thermal expansion rates of the steel gears. It was possible to manufacture the steel housing in FAULHABER's standard production facility. This in turn helped assure the precisely-fitting interchangeability. Thanks to the easily-assembled individual gearhead parts, the spaceworthy "reinforced" parts could then be easily put together. The modified standard drives prove their performance in space just as they already have in many other extreme applications, e.g. in the high vacuum of electron microscopes or in chip production.

Products