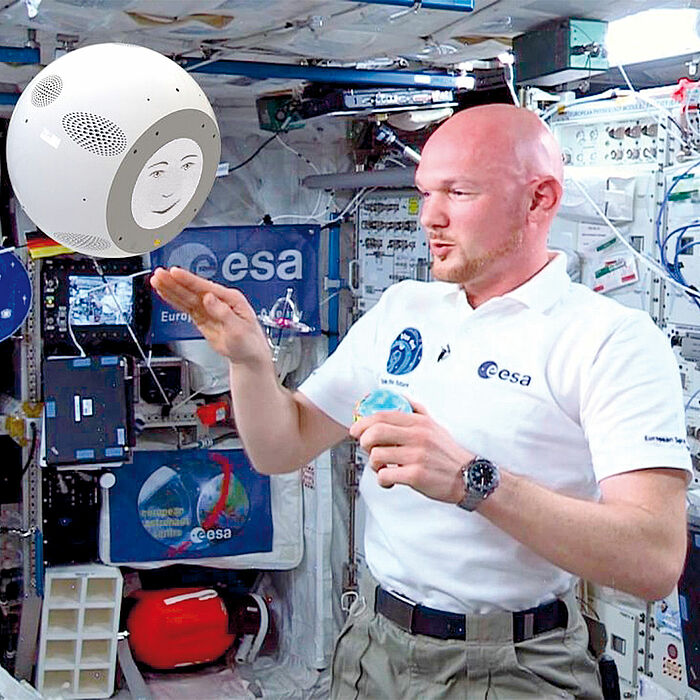

Airbus initially examined the flight assistant concept as part of a self-financed study. Then came the order from the aeronautics division of the German Aerospace Centre (DLR) in August 2016 to go ahead with the project. This was subsequently implemented by a team of around fifty people from Airbus and DLR and the Ludwig Maximilian University in Munich (LMU) in the record-breaking time of less than two years. Also participating were experts from computer manufacturer IBM, upon whose Watson technology the artificial intelligence (AI) of the CIMON project is based. Thanks to this technology, the little helper is able to orientate himself, move, acquire knowledge and recognise his human counterpart.

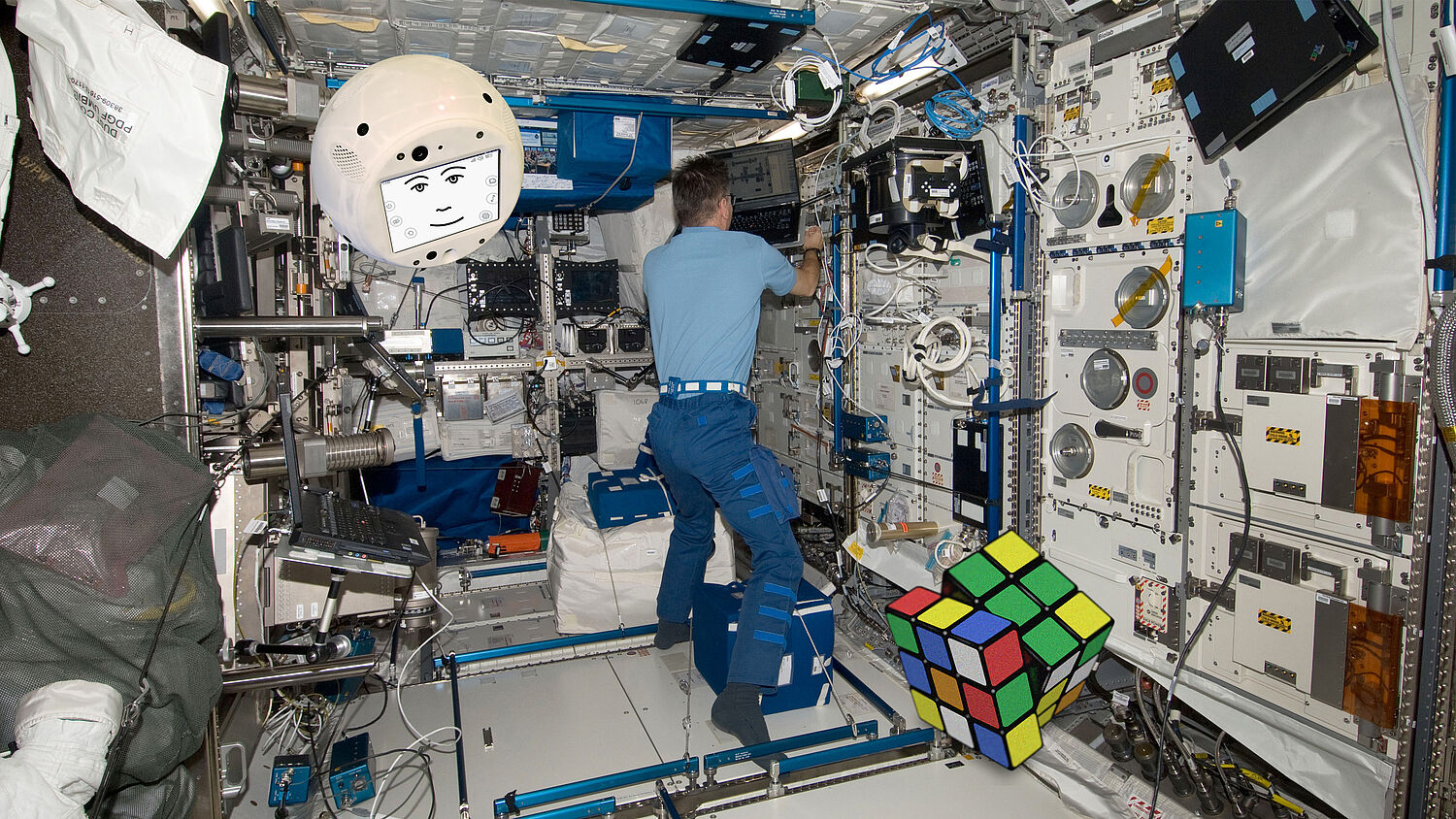

CIMON journeyed to the ISS as part of the Horizons mission. Its work there will initially be limited to three experiments, which it will conduct together with the German crew member and temporary commander Alexander Gerst. Together, they undertake to sort the colours of the Rubik magic cube and carry out an experiment with crystals, as well as a medical experiment. The helper assists with learning processes, gives step-by-step instructions, checks the completion with the help of his built-in camera and intervenes if necessary – of course only verbally – and corrects where needed.

With propeller drive in space

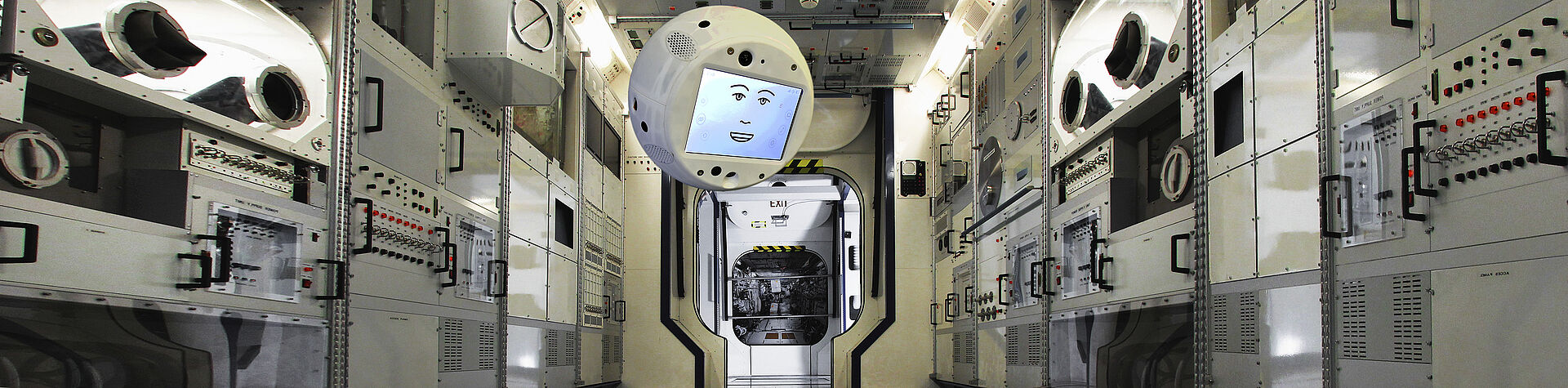

On board the ISS, the spherical robot, the size and shape of a medicine ball, floats weightlessly in space despite its weight of five kilos. To make sure it does not crash into anything and for precise movement, CIMON is equipped with seven tubular air nozzles, each of which has two small propellers. They also allow it to interact using body language.

"Four tubes are provided along the x-axis, which are responsible for forward and backward movement, for which we need the highest speed," explains Philipp Schulien, Science Engineer at Airbus in Friedrichshafen. When the individual propellers are properly controlled, they also give mission companion CIMON the ability to nod or shake his head. Two tubes are provided for lateral movement, one for up and one for down. This arrangement – instead of one larger propeller per axis – was chosen among other things because of the strict noise regulations of the ISS.

When the helper works with a crew member, he must remain in a "box" – an imaginary cuboid within the station. CIMON must do quite a bit of work to stay put, as this box moves circularly with the permanent rotation of the ISS. Moreover, the air on board is constantly circulated. The airflow and rotation would easily push him against the nearest wall if it was not for his resistance.

Automatic thrust pulses

This is why the propellers in its air nozzles regularly push out small thrusts to correct the position. The various movements of the mission companion are controlled by switching the individual propellers on and off as well as by controlling the speed of the individual motors. The latter are brushless servomotors from the 0824 … B series. The SC1801 Speed Controller translates the commands of the navigation software into the proper speed.

"FAULHABER motors have proven themselves in space travel," explains Philipp Schulien. "Since every gram and every cubic centimetre matter when travelling in space, we always need as much driving power as possible with the lowest possible weight and volume. The selected combination is extremely compact. In addition, total reliability, a long service life and low maintenance are just as important. And lastly, the drives should also consume as little energy as possible and be very quiet so that the crew is not disturbed by additional noise." Other FAULHABER motors were also selected for the trip to the ISS for the very same reasons: they drive the peristaltic pumps for a bio-experiment, which is also carried out during the Horizons mission. The astronaut assistant is intended to remain on board after completion of the mission and continue his own training. His feedback will help the earth-bound developers to fine-tune the concept.