A normal pregnancy lasts 40 weeks. During this time, the baby gets everything it needs in the womb. It receives oxygen and nutrients through the umbilical cord; the amniotic fluid and the body heat of the mother ensure the ideal temperature. The mother's movement and touch as well as noises from the body and the outside supply the sensory input that is so important for the development of the brain. A premature birth robs the foetus of these important resources.

Thanks to modern neonatal medicine – the term for the medical care of premature infants – babies still have a good chance of surviving outside of the womb from the 25th week of pregnancy. Approximately 80% of preemies can even make up their growth deficit within the first two years and develop fully normally.

Constant warmth crucial for survival

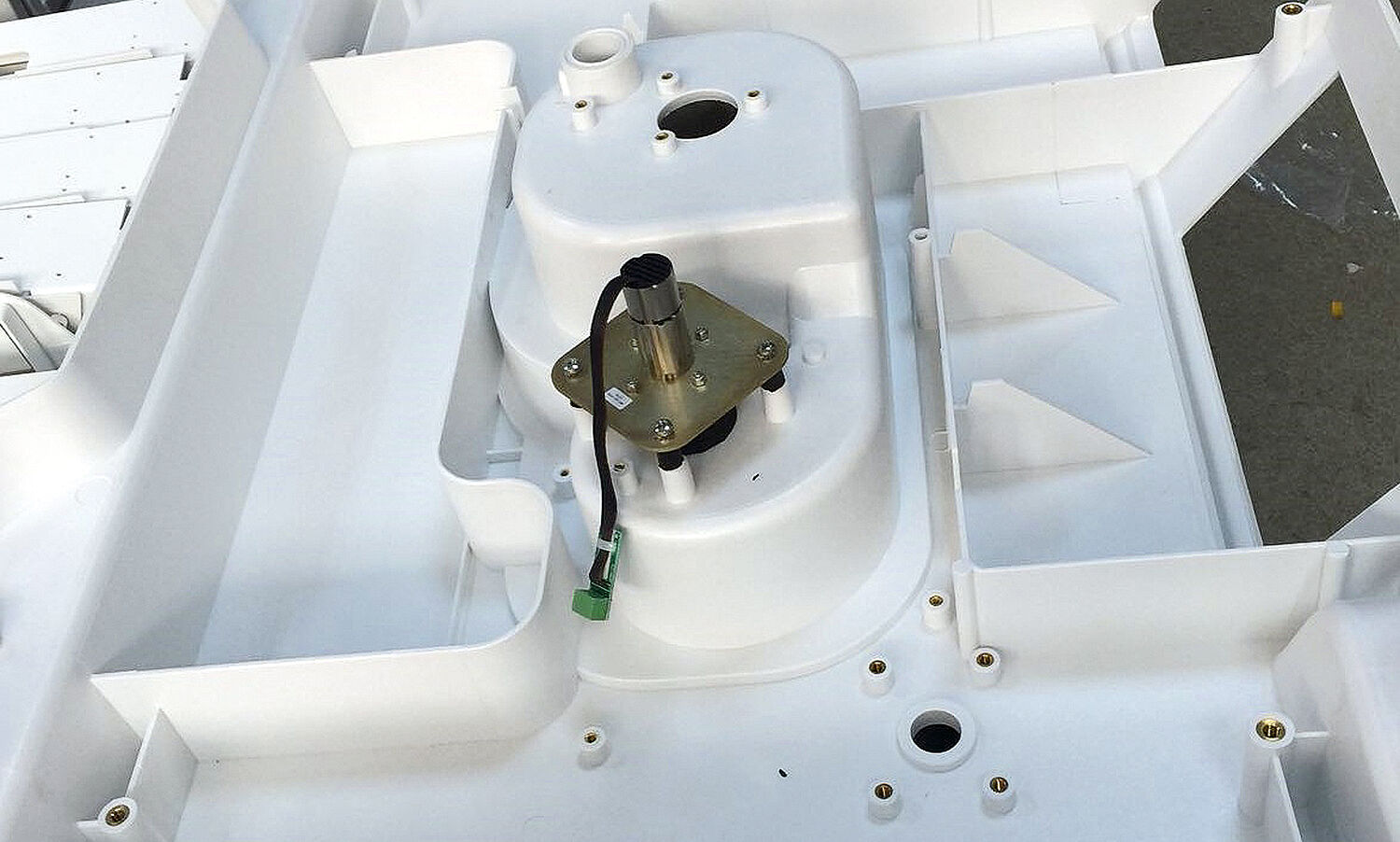

In the first weeks and months, however, they need comprehensive care and the protective environment of an incubator. The incubator simulates the physiological conditions normally present in the mother's womb. In addition to various possibilities to provide assistance with feeding, it offers above all a pleasant and constant warmth as well as consistent air humidity.

These are decisive parameters, as the organs of the child are – depending on the time remaining to the normal due date – more or less significantly underdeveloped. The small body is not yet able to regulate its temperature itself. Furthermore, the lungs often need enriched air to absorb enough oxygen.

"The incubator is supplied with air that is at exactly the right temperature and humidity," explains Ferhat Yıldız, CEO at Tende Elektronik. "The air is transported into the incubator by as if an impeller, i.e., a propeller enclosed in a housing. As a result, this fan is a decisive component for the function of the incubator and for the well-being of the baby."

But the impeller needs to do more than just supply a constant flow of air. After all, the incubator cannot remain closed all of the time. To care for and treat the baby and – of course – for the ever so important body contact with the parents, it is regularly opened completely or partially. The fan then provides an "air curtain", which largely prevents the penetration of cooler air. At the same time, it supplies more warm air to compensate for the nevertheless unavoidable drop in temperature. The speed of the impeller therefore also regulates the temperature in the incubator.

Quiet technology prevents hearing damage

The fan and its electric drive are, however, a noise source that is located very close to the small body. Like the other organs, the ears of the preemie are not yet fully developed, making them especially sensitive. If the noise level rises above a certain, relatively very low value, there is a risk of permanent hearing damage. Because the impeller runs continuously, its operating noise must be considerably below this value.

There is, thus, a clear requirement on the drive: it must run as quietly as possible. The FAULHABER motor achieves this thanks to – among other things – it's ironless design, which eliminates cogging torque: the "jerking" on every revolution that is unavoidable with electric motors with iron armatures cannot occur here. In addition, the noise of the electromagnetic interference is minimised by an integrated speed controller. Because another noise source is the socalled pulse width modulation (PWM): this is used to switch the power supply of the motor on and off in very short intervals. The pulse width – the distance between the switching operations and their corresponding duration – influences the speed and makes precise control possible. The PWM can, however, cause a humming noise. With the brushless DC-Servomotors used here – 2232...BX4 SC for stationary and 3153...BRC for mobile incubators (both models with integrated Speed Controller) – the so-called electrical noise is avoided by the very high frequency of the PWM as well as by foregoing a separate lead wire between motor and electronics.

"Also decisive for minimising the noise is the perfect balance and the tight tolerances of the individual parts," explains Tiziano Bordonzotti. At FAULHABER, he coordinated the cooperation with Tende Elektronik and organised the development of the customerspecific solution. "The outstanding running characteristics of the motors are the result." The exceptionally low noise level of the Tende Elektronik incubators of 4245 dB, which corresponds to a whisper or quiet music, is largely thanks to these motors. An integrated speed controller ensures the precise and reliable control of the drives. This, in turn, helps keep the units very compact and lightweight, which is especially important with the mobile incubators.

Certification for medical technology

Ferhat Yıldız praises the cooperation: "FAULHABER provided us with comprehensive support and developed what is for us the ideal drive. The high quality of the motor matches the high quality of our incubators. Another advantage for us stems from the fact that the production facility for the motor possesses the necessary ISO certificates for medical products, allowing us to install these components without additional certification effort."

Tende Elektronik, explains CEO, began producing incubators for premature babies for other firms as an OEM supplier in the 1990s. The company, which is based in the Ankara Technopolis of the University in the Turkish capital Ankara, has produced under its own name for the past three years. It now exports its products to dozens of countries. This success, Yıldız is certain, is related to the clear focus on quality and innovation: "We are, for example, the first company in the world to directly integrate Masimo Rainbow SET technology to incubators. This enables very sensitive, noninvasive monitoring of the body functions of the newborn."

In addition to the wellbeing of the small patient, yet another aspect plays a decisive role. The incubator is in operation around the clock and the neonatal clinics want to use the devices over long periods of time. "We are aiming for an operating life of at least ten years," says CEO. "The components – i.e., including the motor – must perform their work for a very long time with maximum reliability. With the FAULHABER motors, we know that they are capable of doing this."