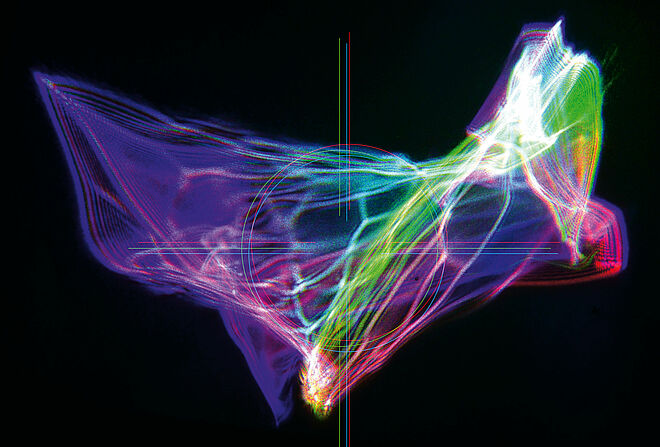

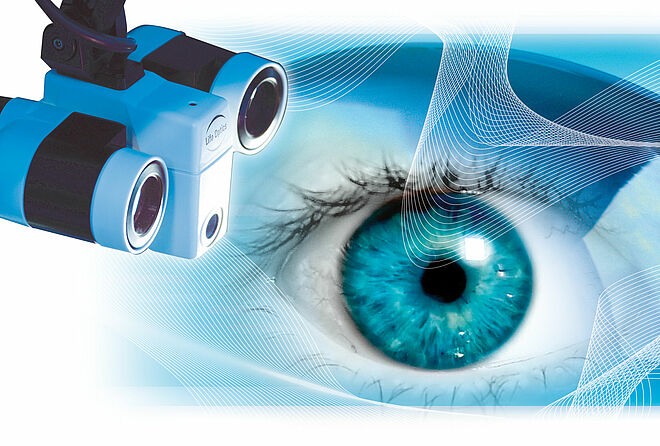

Small cameras for big emotions

Fans want to get as close as possible and the media must deliver: a subtle twitch at the corner of the trainer's mouth, contentious fraction-of-an-inch decisions or once-in-a-lifetime events. In the competition to deliver the most spectacular images, cameras are ahead of the field,...