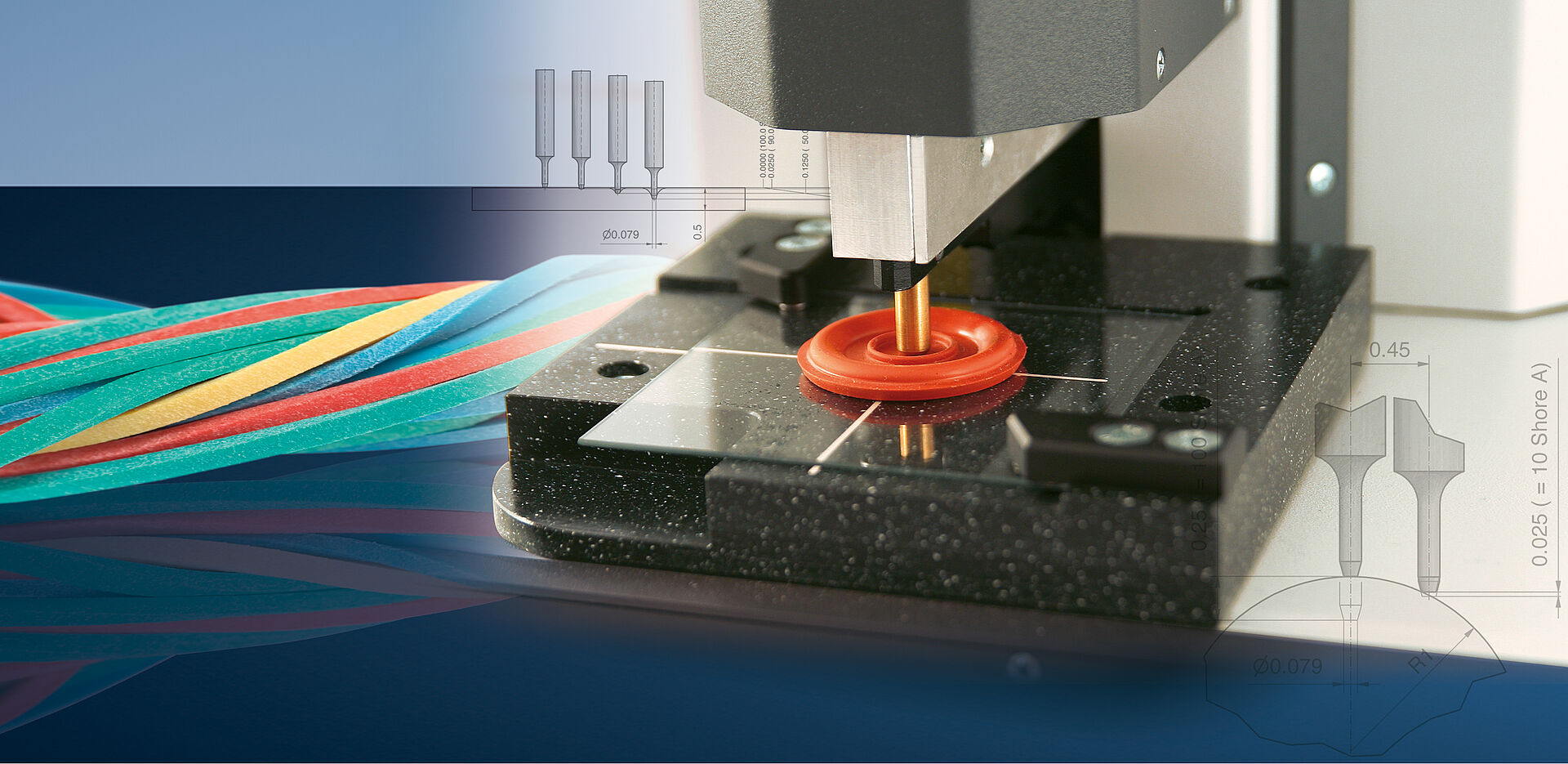

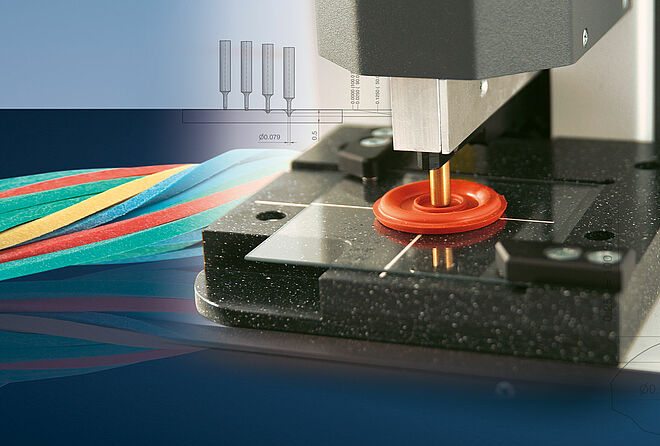

The hardness of a material is one of its key properties. A wide range of procedures can be used to test hardness, including the Vickers, Brinell, Rockwell, Knoop and Shore A hardness tests. For example, the latter is used for components made from elastic polymers: A testing probe presses against the material with a defined force. Electronically commutated DC-servomotors precisely control the force applied. With an integrated Motion Controller and a corresponding communication interface, they form the mechanical link between the measuring computer and the probe.

In other testing tasks too, such drives are used to perform precise movements, for example when positioning sample mounts in three dimensions, moving the turret of testing tool magazines or aligning optical components.

The compact drives must fit in the smallest testing devices and allow intermittent start/stop operation with zero vibration. The graphite-commutated motors of the CR and CXR series in combination with IE3 encoders and planetary gearheads are among the drives particularly well suited to such tasks. In addition to high power from an extremely small volume, they offer a very high resolution. In addition, the position of reference marks and limit switches can be taken into account.

Very similar requirements apply when testing other material properties such as the viscosity of flowing media. It is determined in a measuring pot with a rotating paddle. The viscosity changes the resistance and therefore the torque of the drive. Using DC-servomotors from FAULHABER, for example from the brushless series 4490 … BS, the torque can be read with high precision and repeatability. The integrated, linear Hall sensor enables low speeds. The motor runs without a cogging torque and with an absolutely linear ratio of voltage to speed and current to torque. If desired, FAULHABER can provide the drives as a complete package including motor, gearhead, encoder, brake and controller from a single source.