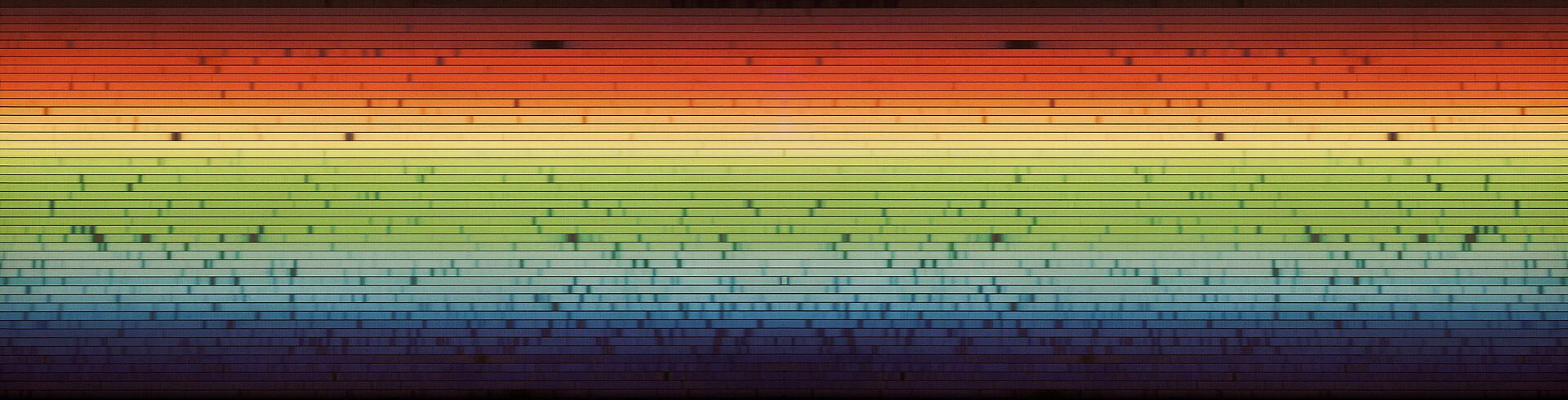

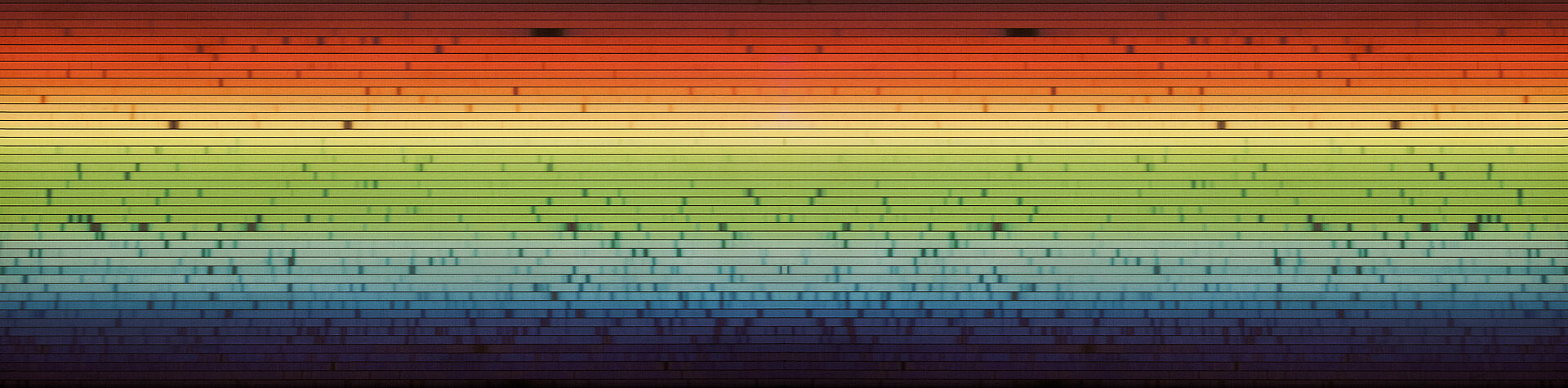

What is my material actually made from? The answer to this question is crucial in many fields, from life sciences and recycling through to incoming goods inspection in the processing industry. Nondestructive material analysis usually uses optical processes such as laser-induced breakdown spectroscopy (LIBS), X-ray fluorescence (XRF) and spectrophotometry. The way in which a material absorbs or reflects the induced radiation provides detailed information about its composition.

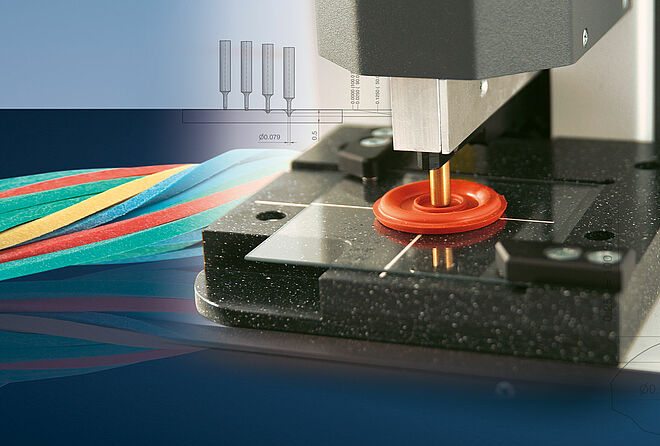

In such optical analytical devices, apertures are opened and closed, filters and filter wheels rotated or positioned, and lenses and mirrors focused with micron precision. Micro drives perform all these tasks in a highly complex and confined environment.

For example, in the spectrophotometer, the sample mount moves along the z-axis. It sits on a fine-thread spindle that is driven by a servomotor with a planetary gearhead. A high-resolution, magnetic encoder supplies the controller with the required precise position data which is used to set the optimal path length.

Other optical elements such as filter wheels and shutters place similar demands on the drive. When they are housed in handheld devices, there are even more requirements: Less space is available and the battery operation means that particularly high energy efficiency is needed.

A comprehensive modular system comprising motors, gearheads and encoders of many different sizes and with many different technologies enables FAULHABER to create the optimal drive for optical material analysis devices. Combining this system with our precision lead screws opens up even more extremely interesting possibilities.