Siemens developed its cutting-edge SIPLACE X Series with the express purpose of providing electronics manufacturers worldwide with an even more cost-effective solution for printed circuit board (PCB) assembly. Alongside an assembly performance of up to 80,000 components an hour and a component spectrum of 01005-components up to 6 x 6 mm, particular emphasis was placed on the high-speed changeover. As is the case with all mechanically sophisticated machines, the issue of drive technology was also of pivotal importance.

In order to be able to address the task with the highest degree of expertise, the team responsible for the SIPLACE X Series joined forces with microdrive specialist FAULHABER. The close level of cooperation in this project provided a solid basis for component streamlining. The result: first-class solutions developed at the initial stage of the project. Thanks to this approach, a high-performance assembly machine was developed for the premium sector – setting new standards for printed circuit board assembly.

Basic principles

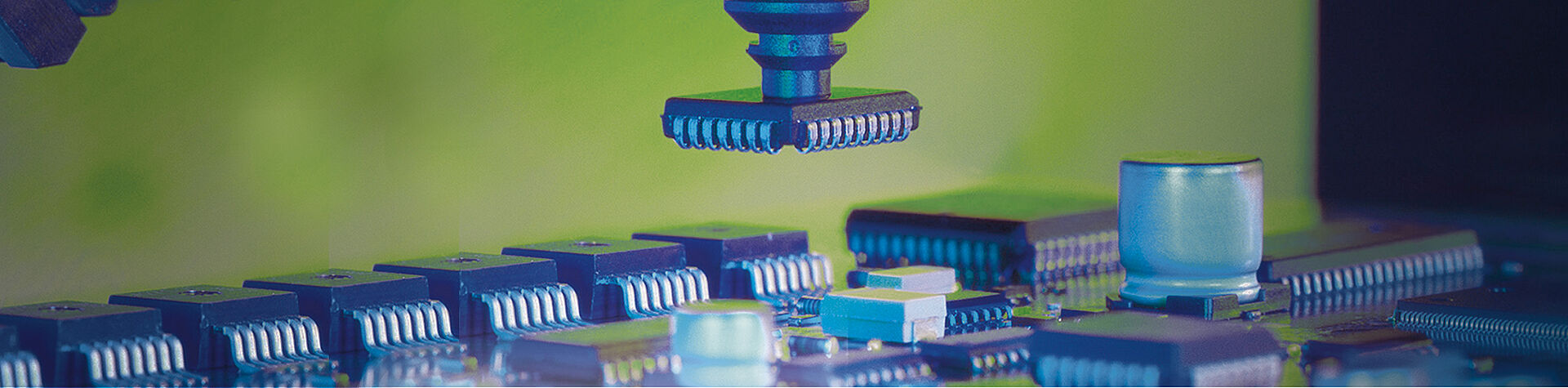

An assembly machine consists of independent components, all of which have to operate "in sync". A placement head attached to a mobile portal collects the components from the conveyor (supply module) and then transports them to the assembly position, i.e. to the printed circuit board, to accurately attach the components. The step between collecting the component and positioning the unit to the printed circuit board requires a considerable amount of time, i.e. the quicker and less frequently this "journey" has to be made, the quicker a product can be manufactured.

Another significant element is the supply of components. Currently, the components are delivered on belts and by rollers. The principle is similar to that used in classic photography (rolls of photographic film). Small pockets on the belt contain the components, and a perforation on the edge of the belt ensures accurate transport. The belt rollers enter into a so-called conveyor, and the belt travels in such a way that a component is always ready for collection by the placement head. As part of this process it is essential to maintain both the exact receiving position and the receiving speed of the head. Supply has to be guaranteed at all times, even when several components, one after the other and from the same belt, are involved.

SIPLACE Collect & Place unit – micro design, macro performance

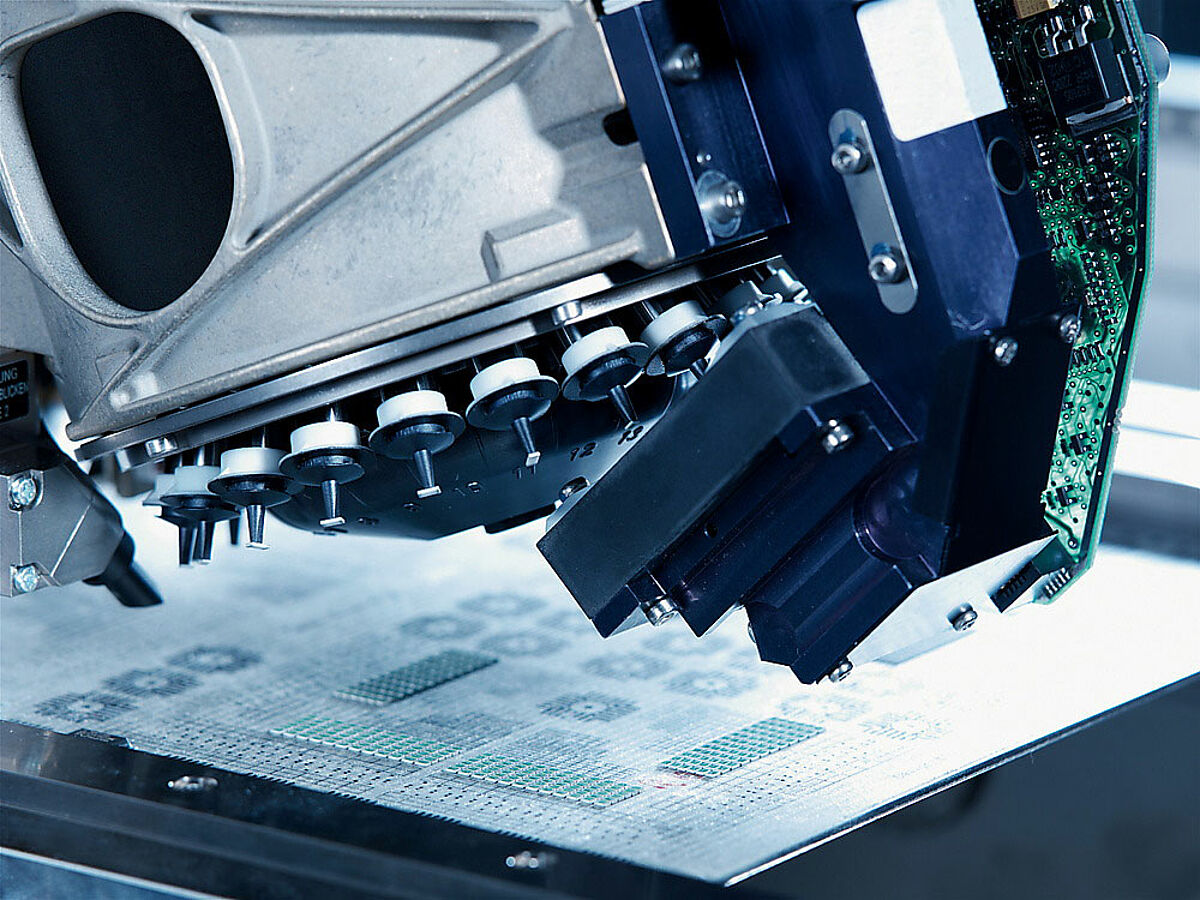

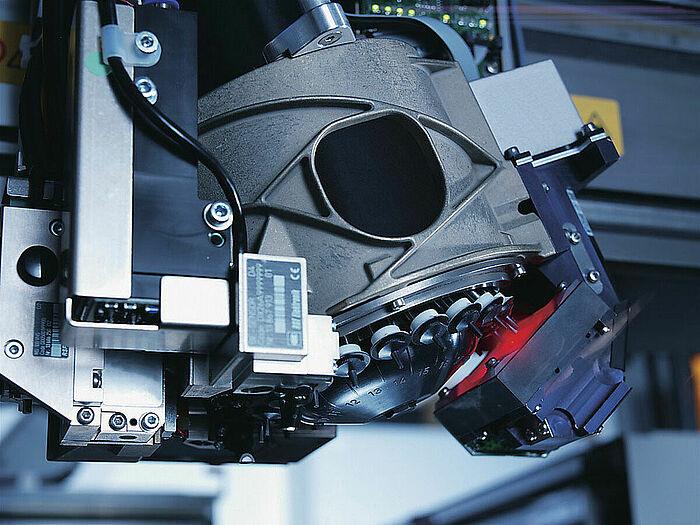

The 20-segment Collect & Place unit, as the heart of this state-of-the-art machine, proved to be particularly challenging. On the one hand, it is a highly dynamic component, calling for ultra-light construction, i.e. without a large mass inertia. On the other hand, it has to be able to hold as many components as possible at any one time. The higher the number of components per cycle, the less frequently the head has to move back and forth between the printed circuit board and the receiving position, which will result in faster operating speeds. The design engineers solved this problem with the new 20-segment Collect & Place (C&P) unit.

The head is capable of extracting and holding the components in place via negative pressure from pipettes. A camera records the components that are firmly connected to the pipette, compares the position with the target position and issues a command for the micromotor on the pipette to turn to the correct position. The 20-segment C&P placement head includes twenty pipettes, each with their own motor. The head itself is slightly conical in shape to provide as large a space as possible for the components. This means that the space in the upper section of the head is marginal, i.e. the motors that align the pipettes with the components have hardly any room to manoeuver. In this case, only a highly specialized design tailored precisely to the space available can produce a compact, light-build solution.

The 20 brushless DC motors, which have a diameter of only 8 to 9 mm including the position sensor, were developed in a slightly conical shape for this purpose. As electronically commutated motors they are particularly suitable for positioning tasks under continuous operating conditions. However, this calls for superior drive control. This is where the partnership between the two experts proved decisive. Instead of using two separate controllers for the motors and the other components of the head, the team opted for synergy. The control electronics for the motors are integrated into the control board of the other components, thus taking up substantially less space. The size and mass are scaled down, while assembly performance is increased.

Component supply, quick & precise

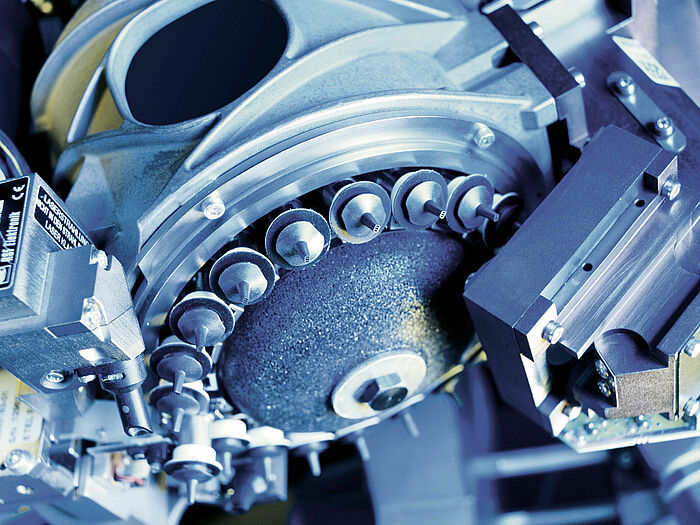

In order to make the most of the superior operating performance associated with the 20-segment C&P head, the supply of components must also be performed with utmost precision. Alongside higher speeds, simple changeover during operation and universal application were defined as key objectives. Until recently, the standard for component feed was a conveyor with a width of 30 mm or more, which could accommodate one, two or three belts (standard belt widths: 8, 12, 16 up to 88 mm wide). When changing a component all belts had to be exchanged with the conveyor, even if only one component was different. In order to increase efficiency, the aim was to incorporate three independent conveyors in the designated space of approx. 30 mm provided by the Triple Feeder. Up until now comparatively "large" micromotors, at 15 mm in diameter, were used for the drives: two next to each other and the third set to the rear.

However, the requirement for the new motors in the X-Feeder was a maximum diameter of approx. 10 mm. Thanks to special high-energy magnets, these new motors are capable of achieving performance levels like those associated with conventional 20...25 mm motors. When one considers that performance normally increases or decreases in motors along with the square of the diameter, the achievement by the design engineers is all the more impressive. At the same time, the drive system has to absorb the traction of the belt. Generally, this amounts to several Newtons of tensile force; beyond this point, the perforation of the belts will tear. This requirement, which is unusual for small drives, was met by microdrive specialist FAULHABER by using two motors for each belt transporter.

The offset motors operate on a common helical gear shaft, which in turn drives the gear wheel for the belt transporter. This device ensures that the necessary dynamics and the torque curve up to the safe range are maintained at all times. The X-Feeder drive therefore ensures reliable positioning of ±25 µm at cycle times of less than 40 ms. This facilitates a secure supply of components with the 20-segment C&P head.

Products